Wave-guide cavity in use for microwave sulfur lamp

A waveguide cavity and sulfur lamp technology, applied in the field of waveguide cavity, can solve the problems of time-consuming and labor-intensive, and achieve the effect of suppressing the spark phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

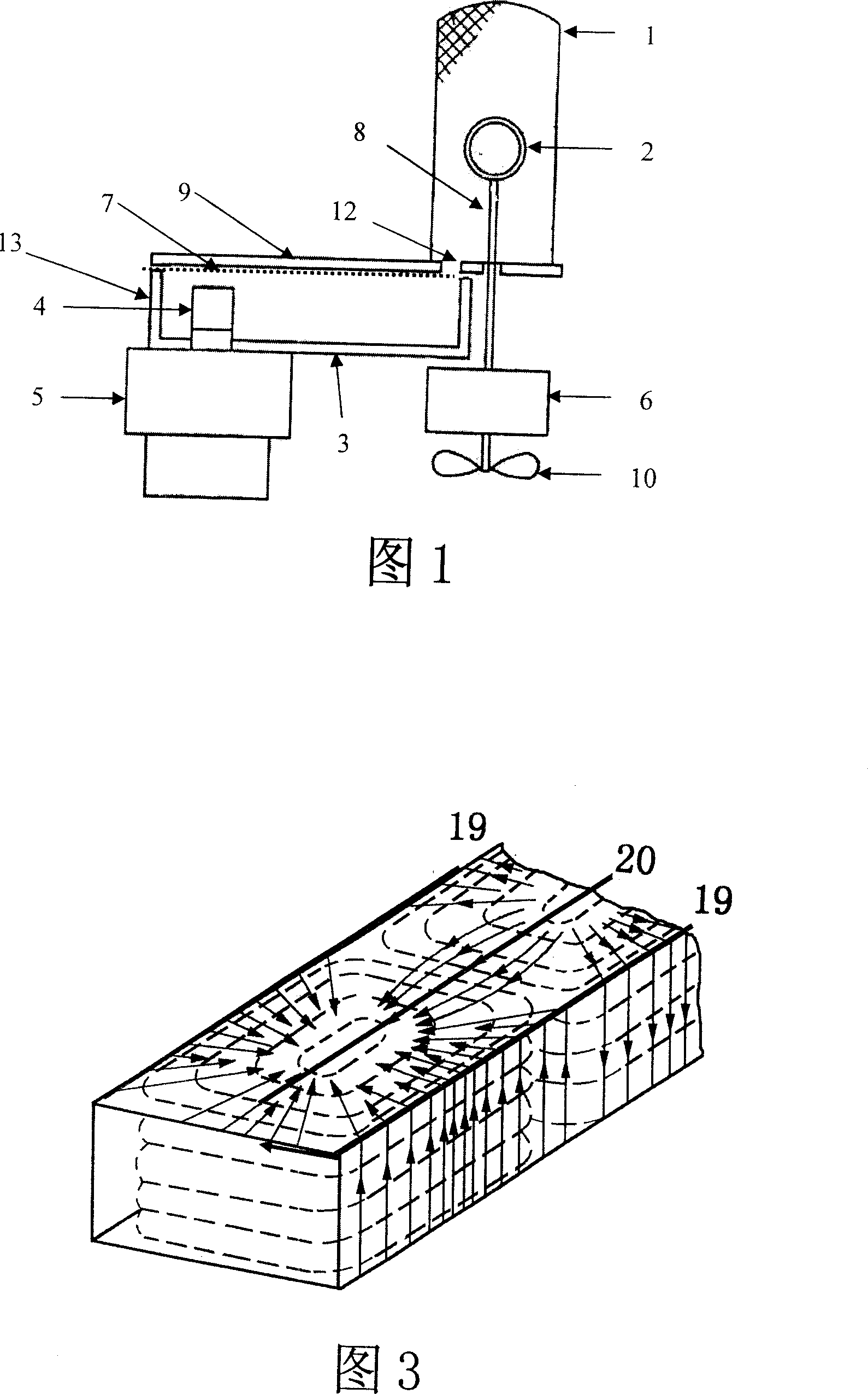

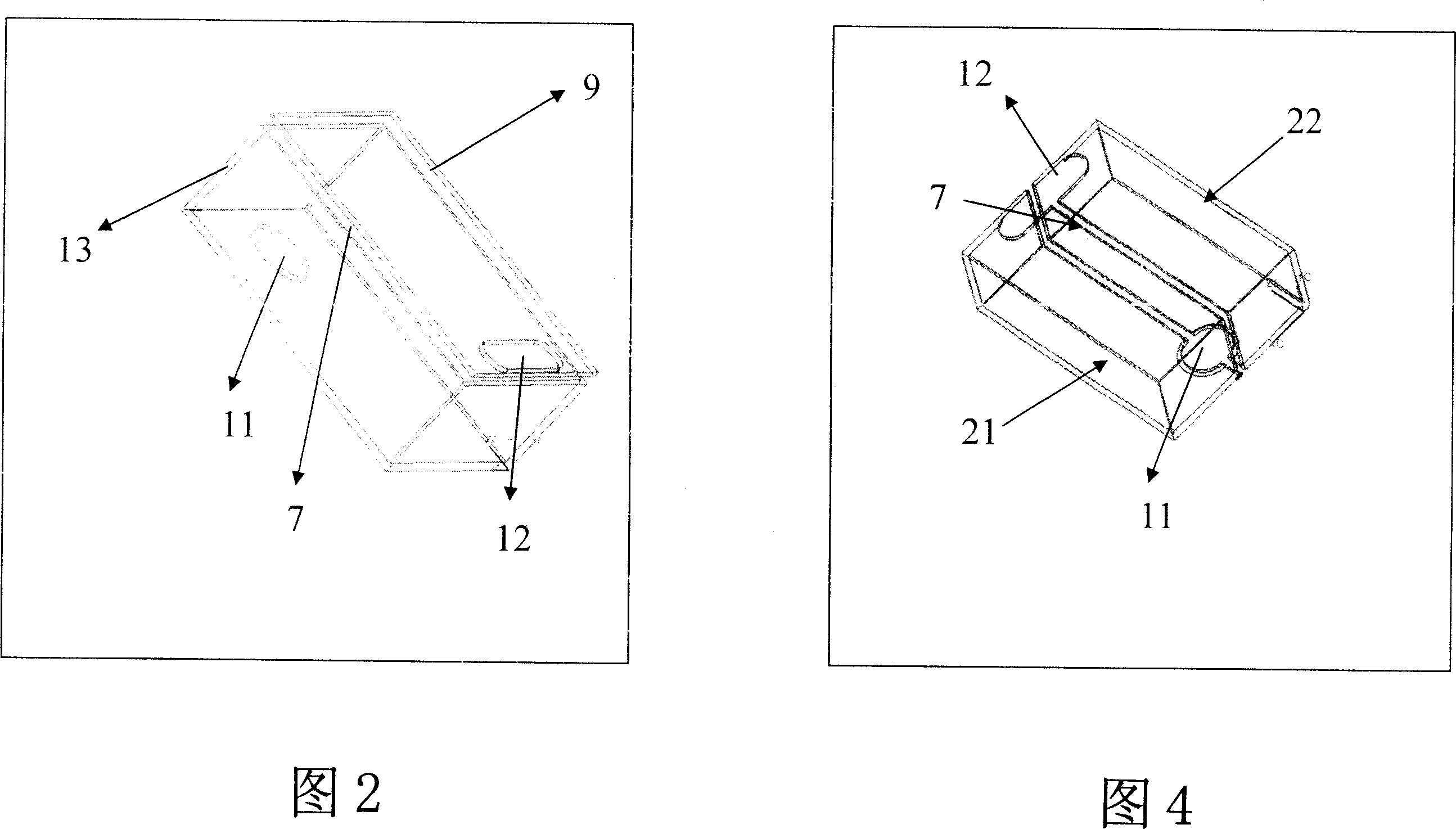

[0015] Referring to Fig. 4, the waveguide cavity is formed by docking the front cavity 22 and the rear cavity 21. The front cavity 22 and the rear cavity 21 are made of metal aluminum die-casting, and the magnetron input hole 11 and the radiation hole 12 are connected together. And molded by die casting, the butt joint of the front cavity body 22 and the rear cavity body 21 is located at the centerline of the waveguide cavity, and finally they are connected into one body with bolts (not shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com