pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, rolling resistance optimization, etc., can solve problems such as radio noise and driver discomfort, and achieve radio noise suppression, easy formation, and productivity. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

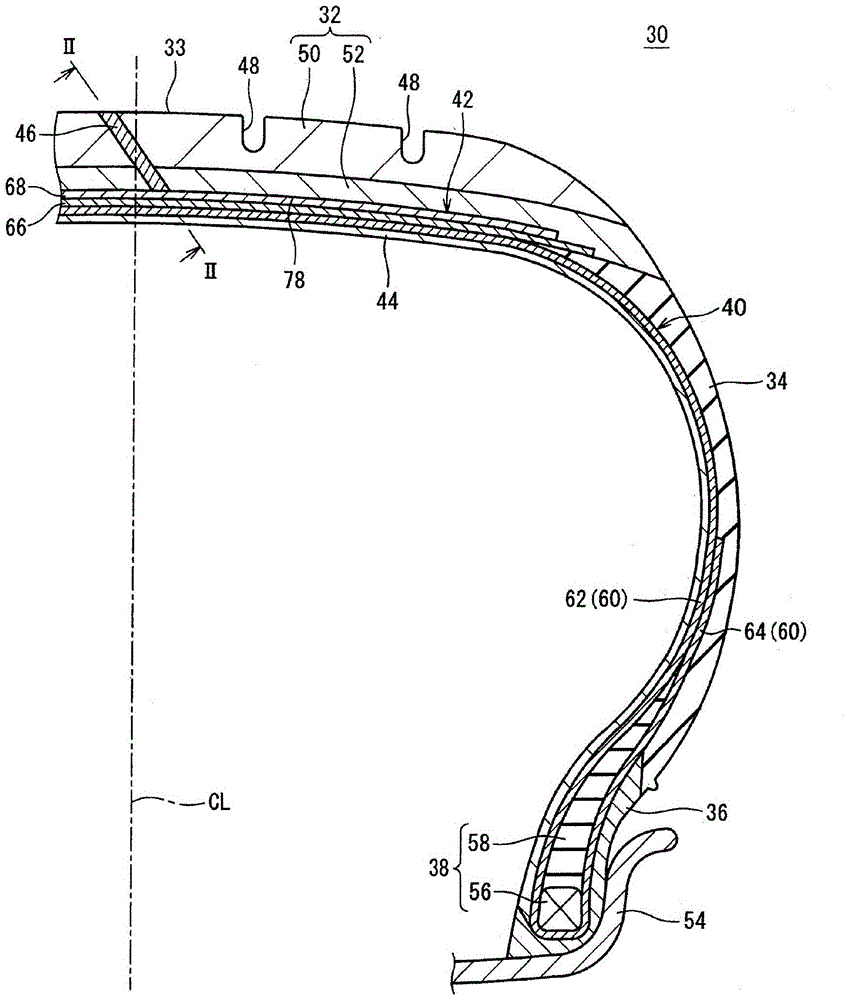

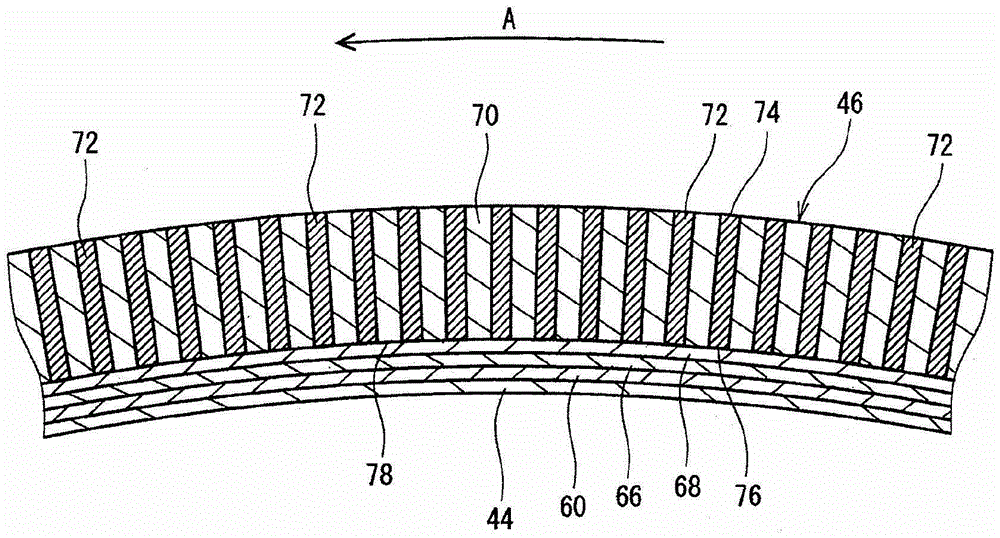

[0112] made with figure 1 and 2 The structure of the tire shown. The size of this tire is "195 / 65R15". The tire has a through portion. The penetrating portion has a topping rubber and a cord. The topping rubber is molded by crosslinking a rubber composition. The rubber composition comprises: 100 parts by mass of styrene-butadiene copolymer (trade name "SBR1500" of JSR Company), 50 parts by mass of silicon dioxide (trade name "ULTRASILVN3" of Degussa Company), 5 parts by mass Silane coupling agent (trade name "Si69" of Degussa Company), 1 part by mass of wax (trade name "SUNNOCN" of Ouchi New Chemical Industry Co., Ltd.), 2 parts by mass of anti-aging agent (Trade name "SUNNOCN" of Ouchi New Chemical Industry Co., Ltd. product name "NOCRAC6C"), 1 part by mass of stearic acid (NOF Corporation), 3 parts by mass of zinc oxide (trade name "Yaqianhua No. 1" of Mitsui Metal Mining Co., Ltd.), 1.5 parts by mass of powdered sulfur (Tsurumi Chemical Co., Ltd.) and 1 part by mass ...

Embodiment 2-15

[0115] Tires of Examples 2-15 were obtained in the same manner as in Example 1, except that the specifications of the penetration portions were as shown in Tables 1-4 below.

Embodiment 16

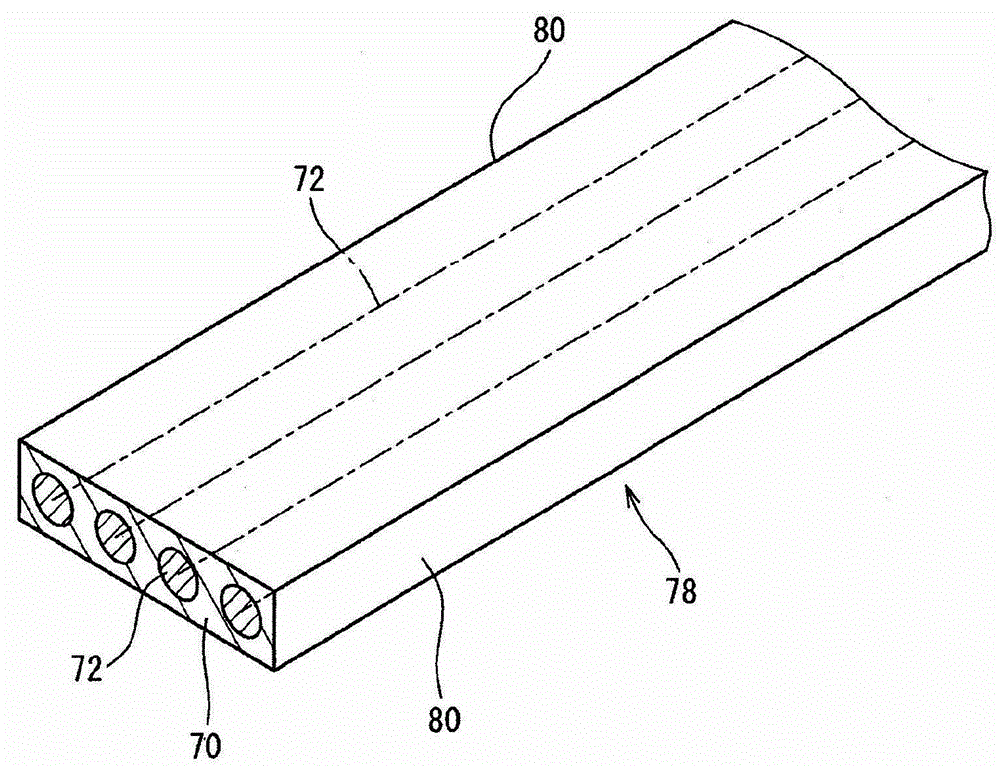

[0121] Filament bundles are formed by twisting non-conductive filaments and conductive filaments. The conductive filaments are formed of polypyrrole. The non-conductive filaments are formed from nylon 66. The fineness of this filament bundle was 1400 dtex / n. The filament bundle is twisted to form a cord. The intrinsic volume resistance of the cord is 1×10 3.2 Ω·cm. The cord has a diameter of 0.32 mm. The angle of the cord with respect to the circumferential direction is 90°. The cord has a length of 1.5 cm. These cords have a density of 15 Ends / 5 cm. The total volume of cords contained in 1 tire is 0.66cm 3 . Other configurations were the same as in Example 1 to obtain a tire of Example 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com