External joint part of a synchronous rotating joint for a wheel hub unit

A constant-speed universal joint and external joint technology, applied in the direction of rotating parts, wheel hubs, vehicle parts, etc., which are resistant to centrifugal force, and can solve problems such as wear and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

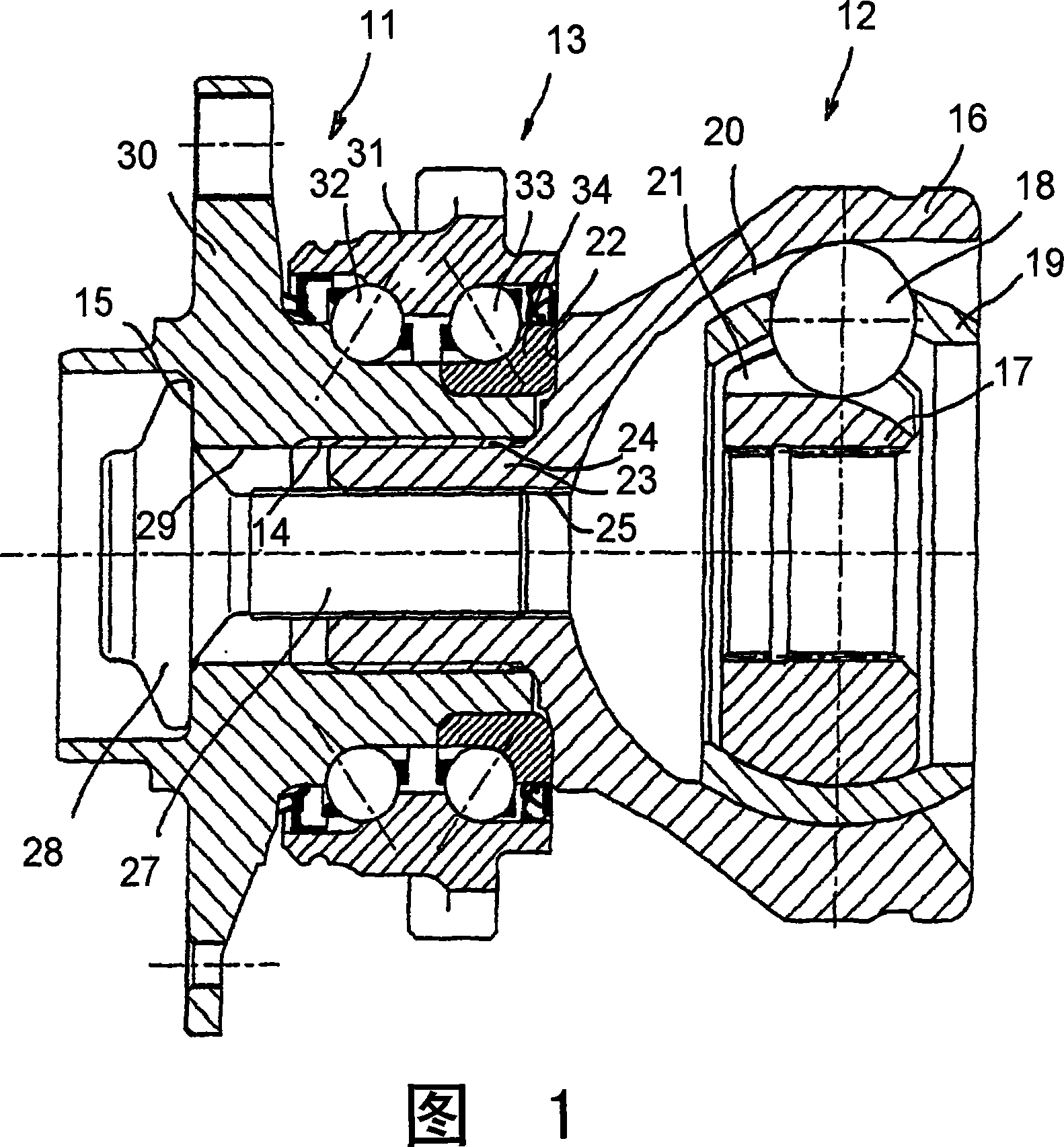

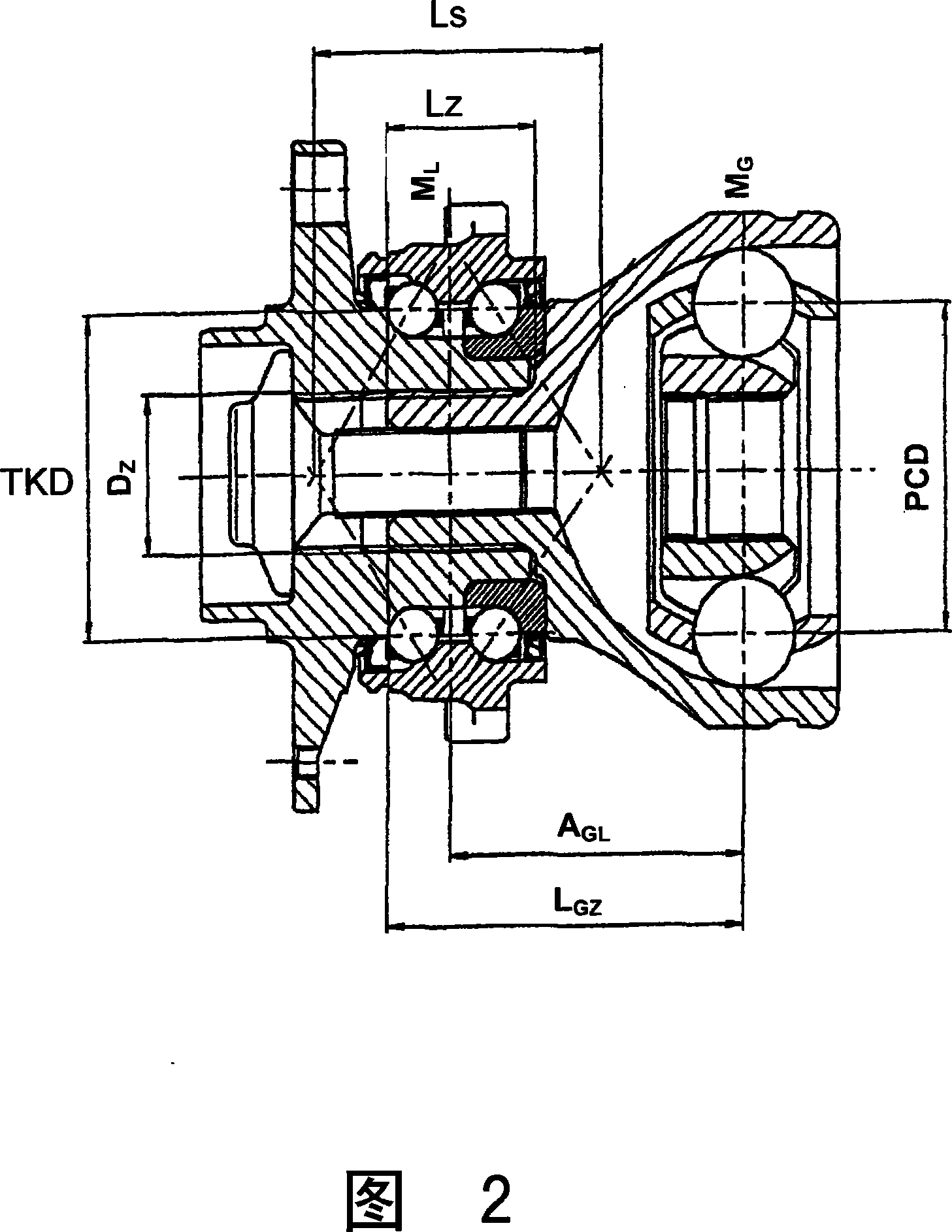

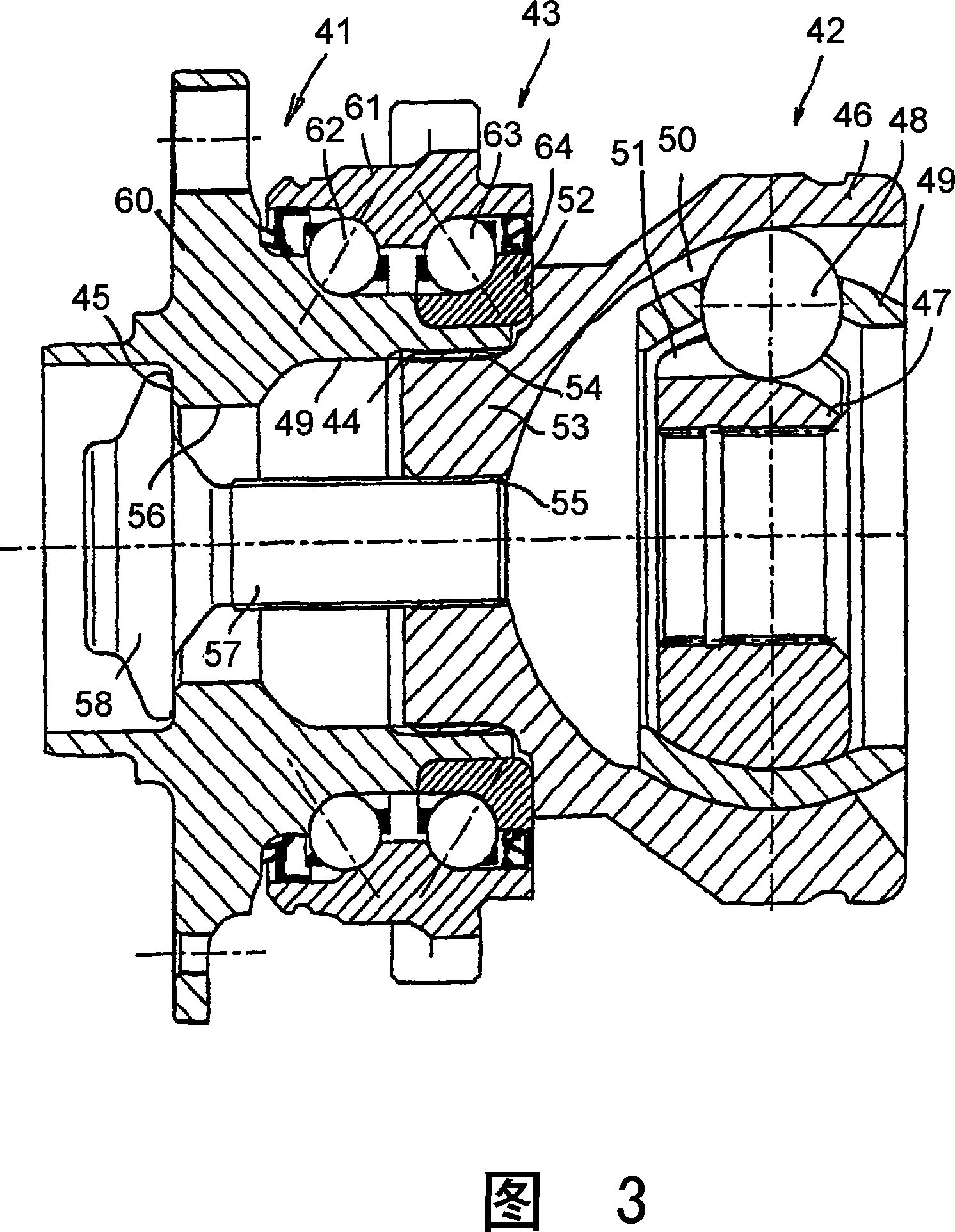

[0022] Figures 1 and 2 each show a hub unit 11 for a drive wheel of a motor vehicle, which has a constant speed fixed joint 12 connected to a drive shaft. The hub unit 11 includes a hub 30 and a bearing unit 13, wherein the bearing unit 13 is slidably fitted to the hub 30 and clamped between the hub 30 and the constant-speed fixed joint 12 in the axial direction. The hub 30 includes a flange screwed to a wheel, and a brake disc can also be screwed to the wheel. In addition, the hub 30 includes a through hole 29, and the inner shaft teeth 14 are formed into the through hole from the joint end. A support surface 15 which is located in the center and is substantially radial is formed on the flange. The constant speed fixed joint 12 is arranged in the form of a UF joint (no undercut joint), and includes an outer joint part 16, an inner joint part 17, a torque transmission ball 18 and a ball cage 19. The balls are held and guided in the outer ball track 20 in the paired outer joint par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com