Main circuit of IGBT full bridge inverse conversion power

A full-bridge inverter and main circuit technology, which is applied to electrical components, output power conversion devices, and AC power input to DC power output. problem, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

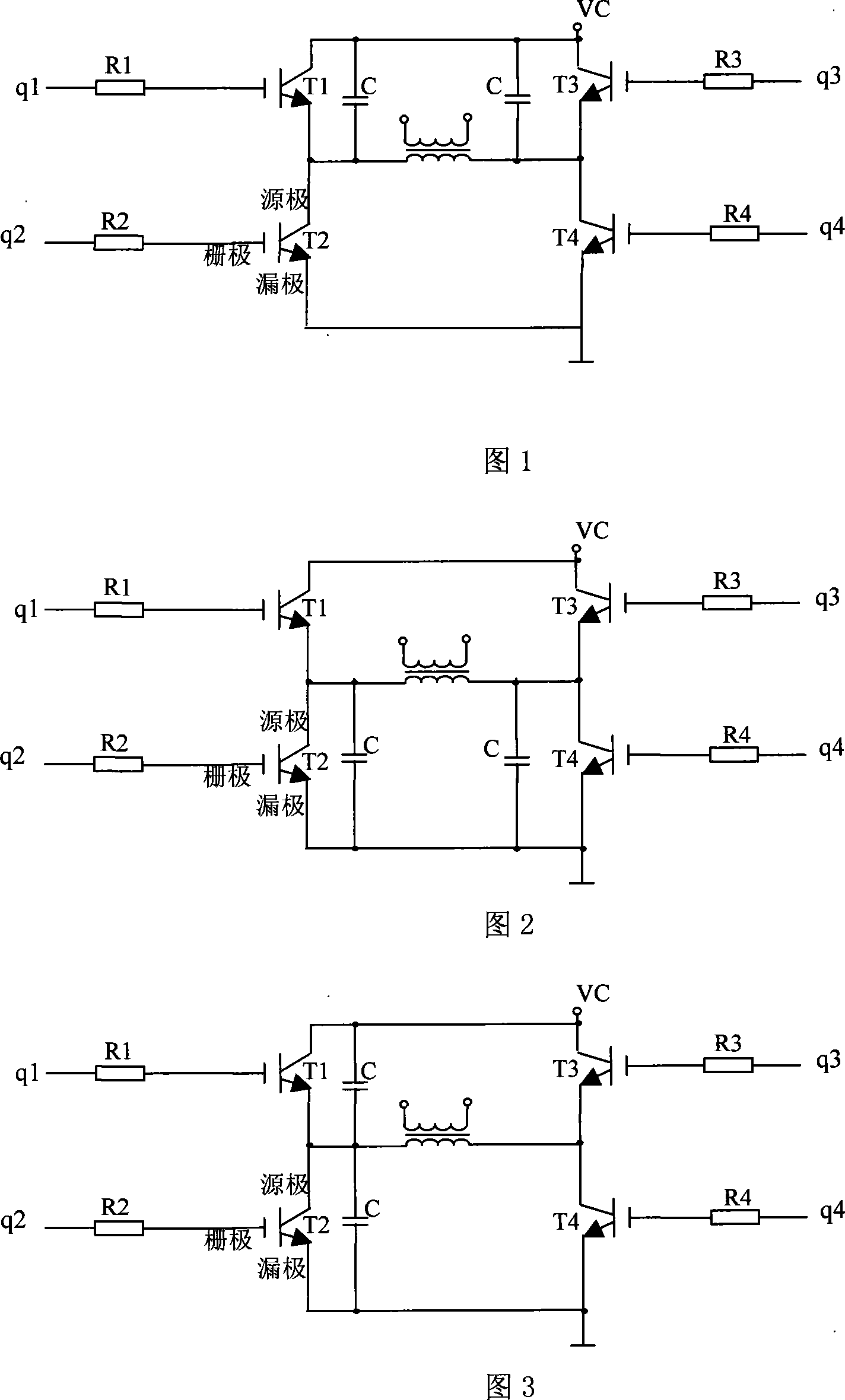

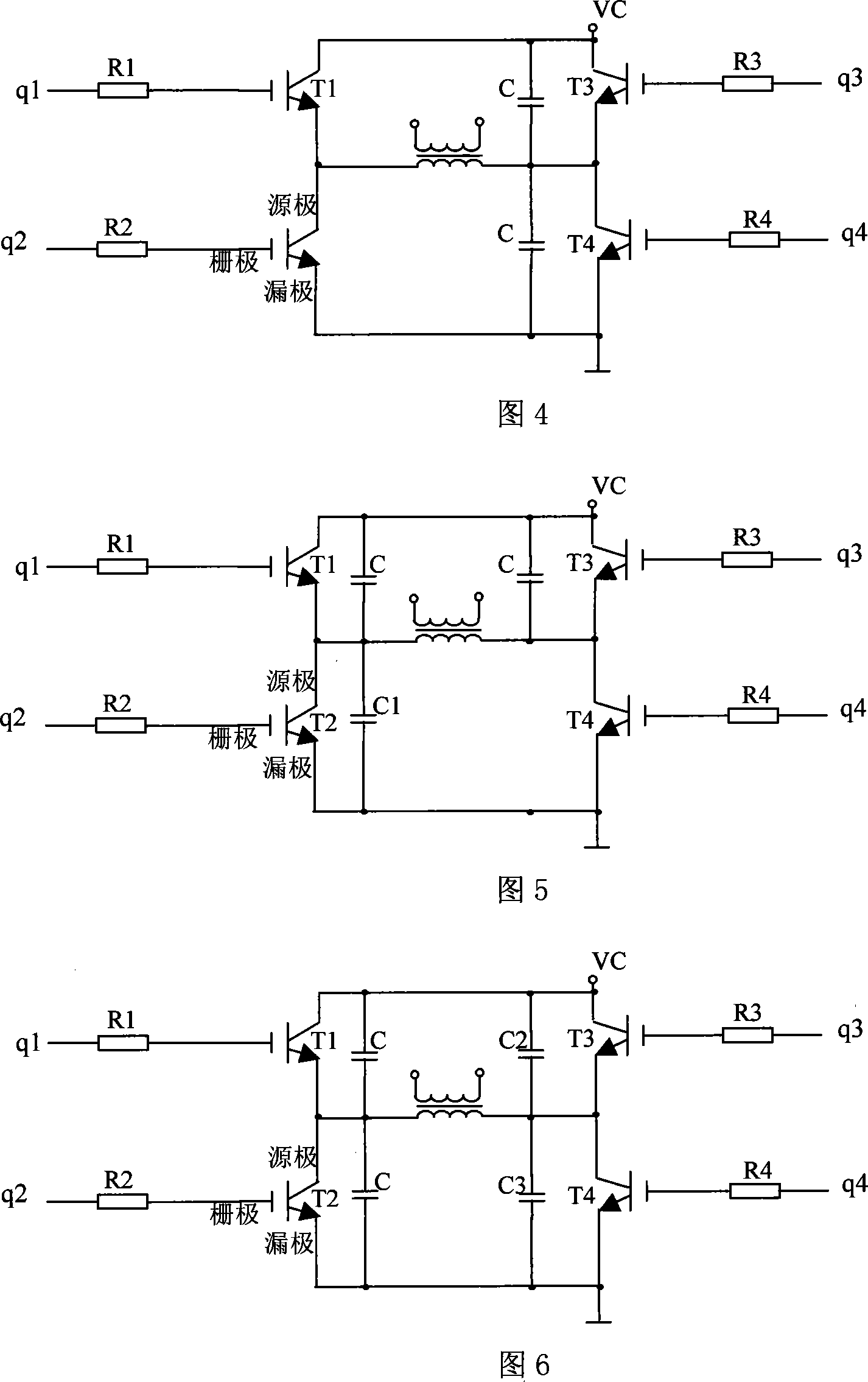

[0016] See attached Figure 1.

[0017] The main circuit of the IGBT full-bridge inverter power supply includes four bridge arms composed of four IGBT tubes T1, T2, T3, T4, low-resistance drive sources q1, q2, q3, q4, output main transformer, and IGBT tubes T1, T2 The gates of, T3, T4 are respectively connected in series with driving resistors R1, R2, R3, R4, and two IGBT source-drain bypass capacitors C.

[0018] Namely R1=R3=a; R2=R4=b; parameter selection a=1.2~5b, a=1.2Ω~500Ω, b=1Ω~100Ω, the source and drain of the two IGBT transistors T1 and T3 bypass capacitors respectively C, capacitance C=200pF~10000pF.

example 2

[0020] See Figure 2.

[0021] That is, R1=R3=a; R2=R4=b; parameter selection b=1.2~5a, a=1Ω~100Ω, b=1.2Ω~500Ω, the source and drain of 2 IGBT transistors T2 and T4 bypass capacitors respectively C, capacitance C=200pF~10000pF.

example 3

[0023] See Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com