Double array direct insertion integrated pin shaping method and device

A dual-in-line, integrated block technology, applied in the direction of electrical components, electrical components, etc., can solve the problems that the pins of the integrated block are not completely vertical, can not save time and effort, and it is difficult to accurately grasp the scale, so as to improve Reliability and consistency, avoid device damage, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

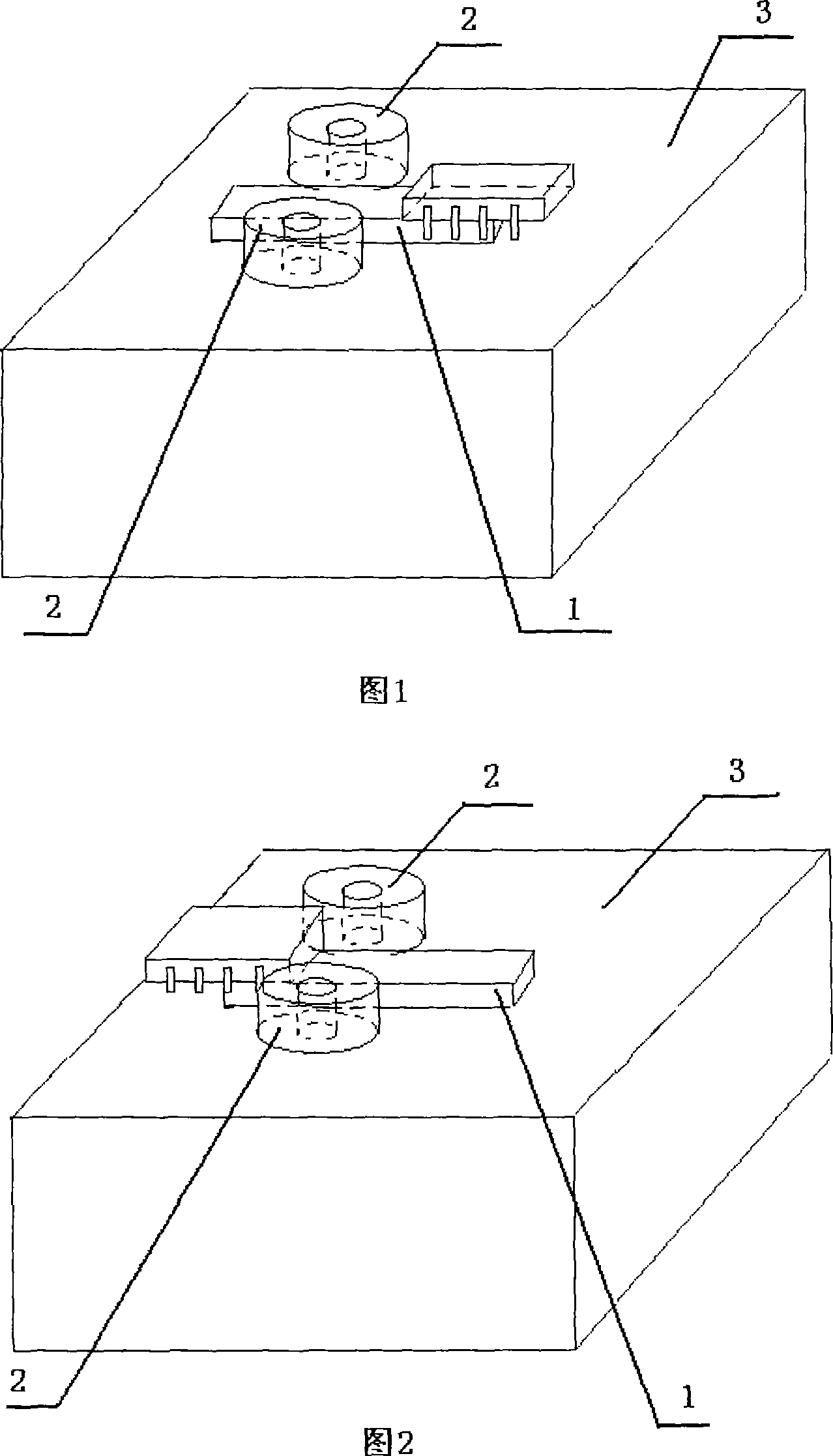

[0026] The double-in-line integrated block pin shaping device includes a base 3 , a bracket 1 , and a cylindrical rolling bearing 2 . The support 1 is fixed on the base 3 with studs, and there are two rolling bearings 2, which are installed on both sides of the support 1 respectively. Base 3 weighs 1000g. The radius of the cross-section of the two rolling bearing cylinders is the same, and the rolling bearings can rotate freely.

[0027] The support is a strip profile, which is divided into upper and lower parts. The upper part can just place the dual in-line integrated block, so that the pins are on both sides of the profile, and the width of the two sides of the lower part is slightly larger than the width of the same position of the upper part, and the difference between the two widths is not less than the thickness of the pins. This structure makes the cylindrical rolling bearings close to the two sides of the lower part of the bar profile, while leaving a gap with the t...

example 2

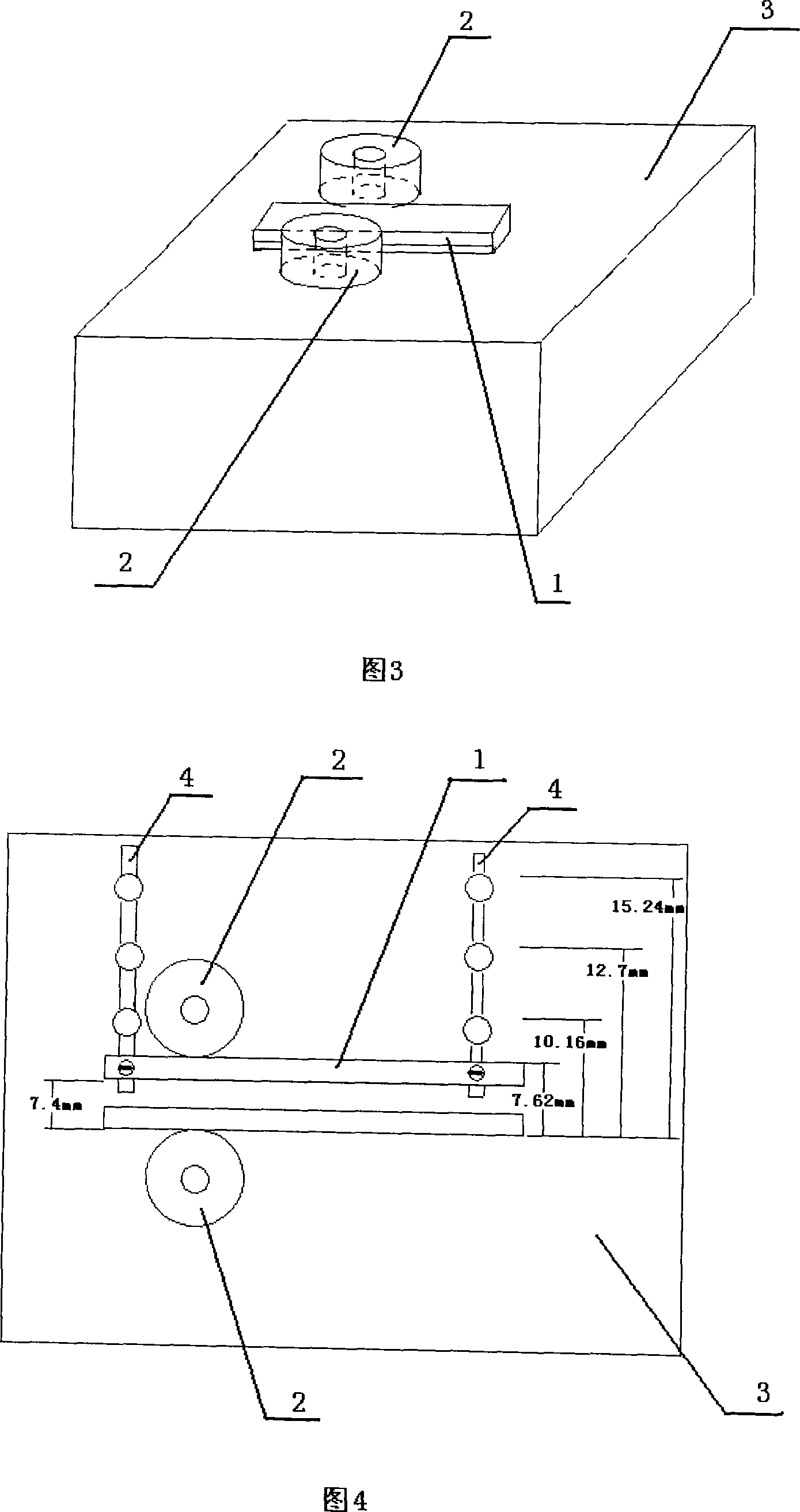

[0031] The double-in-line integrated block pin shaping device includes a base 3 , a bracket 1 , and a cylindrical rolling bearing 2 . The bracket 1 is fixed on the base 3, and there are two rolling bearings 2, which are installed on both sides of the bracket 1 respectively. Base 3 weighs about 1000g. The radius of the cross-section of the two rolling bearing cylinders is the same, and the rolling bearings can rotate freely.

[0032] The bracket 1 is composed of two parallel movable brackets, and the two movable brackets and their corresponding rolling bearings are respectively installed on the base 3 through studs, and can move along a straight line where the two rolling bearings are located. The base 3 is provided with a guide rail 4 corresponding to the stud, and the stud moves along the guide rail 4 . The guide rail 4 is respectively provided with screw holes at the distances of the two movable supports at 7.4 to 7.62mm, 10.16mm, 12.7mm and 15.24mm.

[0033] Before use, ...

example 3

[0035] The double-in-line integrated block pin shaping device includes a base 3 , a bracket 1 , and a cylindrical rolling bearing 2 . The bracket 1 is fixed on the base 3, and there are two rolling bearings 2, which are installed on both sides of the bracket 1 respectively. Base 3 weighs about 1000g. The radius of the cross-section of the two rolling bearing cylinders is the same, and the rolling bearings can rotate freely.

[0036] Bracket 1 is composed of two parallel movable brackets, one movable bracket and its corresponding rolling bearing are fixed on the base 3, the other movable bracket and its corresponding rolling bearing are installed on the base 3 through studs, and can be moved along The two rolling bearings move in a straight line; the base 3 is provided with a guide rail 4 corresponding to the stud, and the stud moves along the guide rail 4 . The guide rail 4 is respectively provided with screw holes at the distances of the two movable supports at 7.4 to 7.62m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com