Large granules vibrating sizing screen

A grading sieve and large-grained technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large overall height, large vibration mass, and many pipe beams, so as to reduce the mass of vibration vibration, improve reliability, The effect of power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

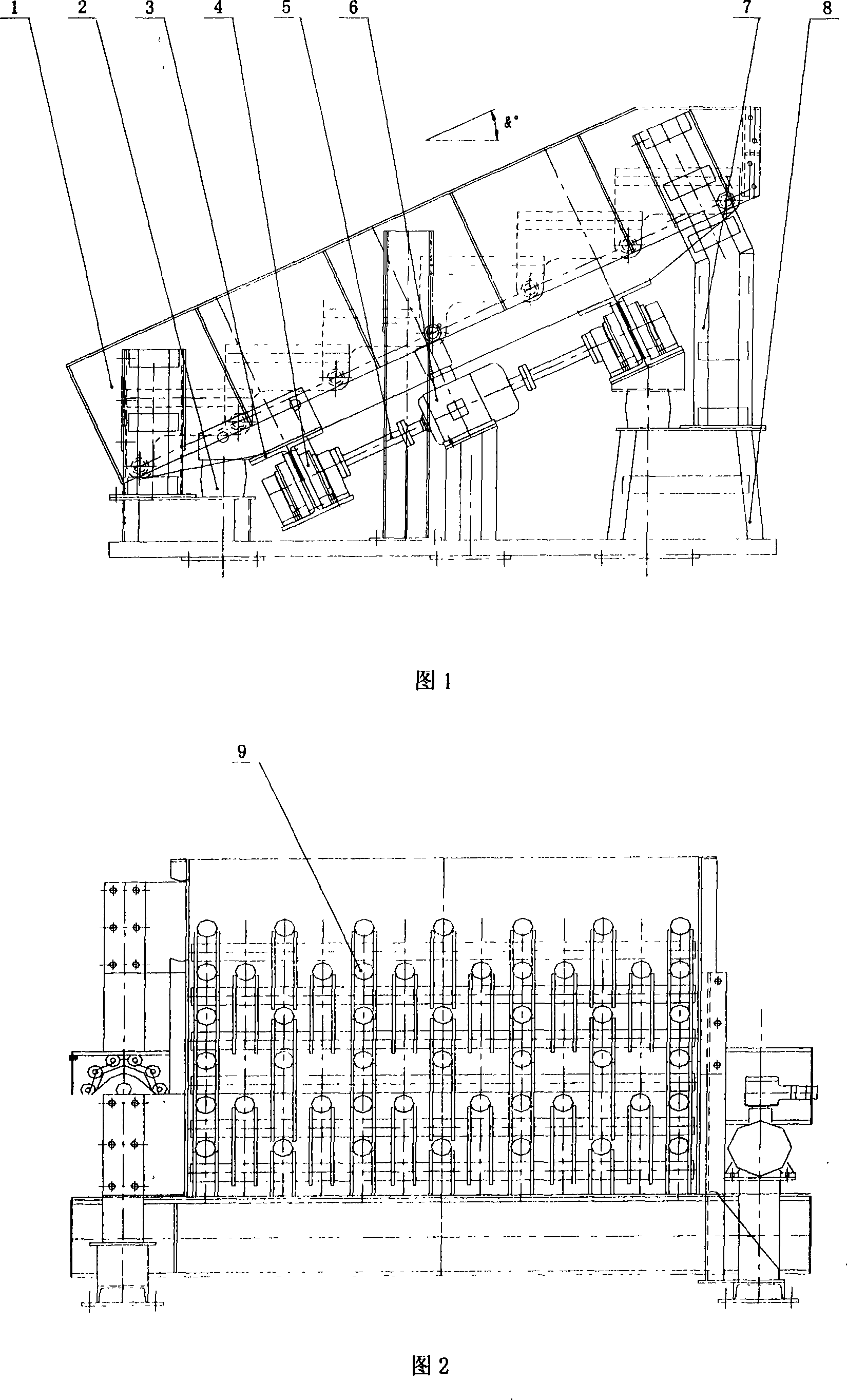

[0012] As shown in Figure 1 and Figure 2, the screen is mainly composed of a screen frame 1, a trapezoidal screen frame 9, an excitation beam 3, an exciter 4, a double output shaft motor 6, a coupling 5, a base 8 and a vibration damping device composition. The screen frame 1 is composed of a surrounding plate and a support, and the screen frame 1 is fixed on a base 8 through a screen frame support 7 . The trapezoidal screen frame 9 is fixed on the base 8 by the spring 2, and the trapezoidal screen frame 9 is made of round steel and supporting steel plates. The trapezoidal screen frame 9 is provided with double exciting beams 3, and the two ends of the exciting beams 3 are equipped with exciters 4, and the exciters 4 are connected with double output shaft motors 6 through flexible couplings 5. The motor 6 is fixed on the base 8 through supports.

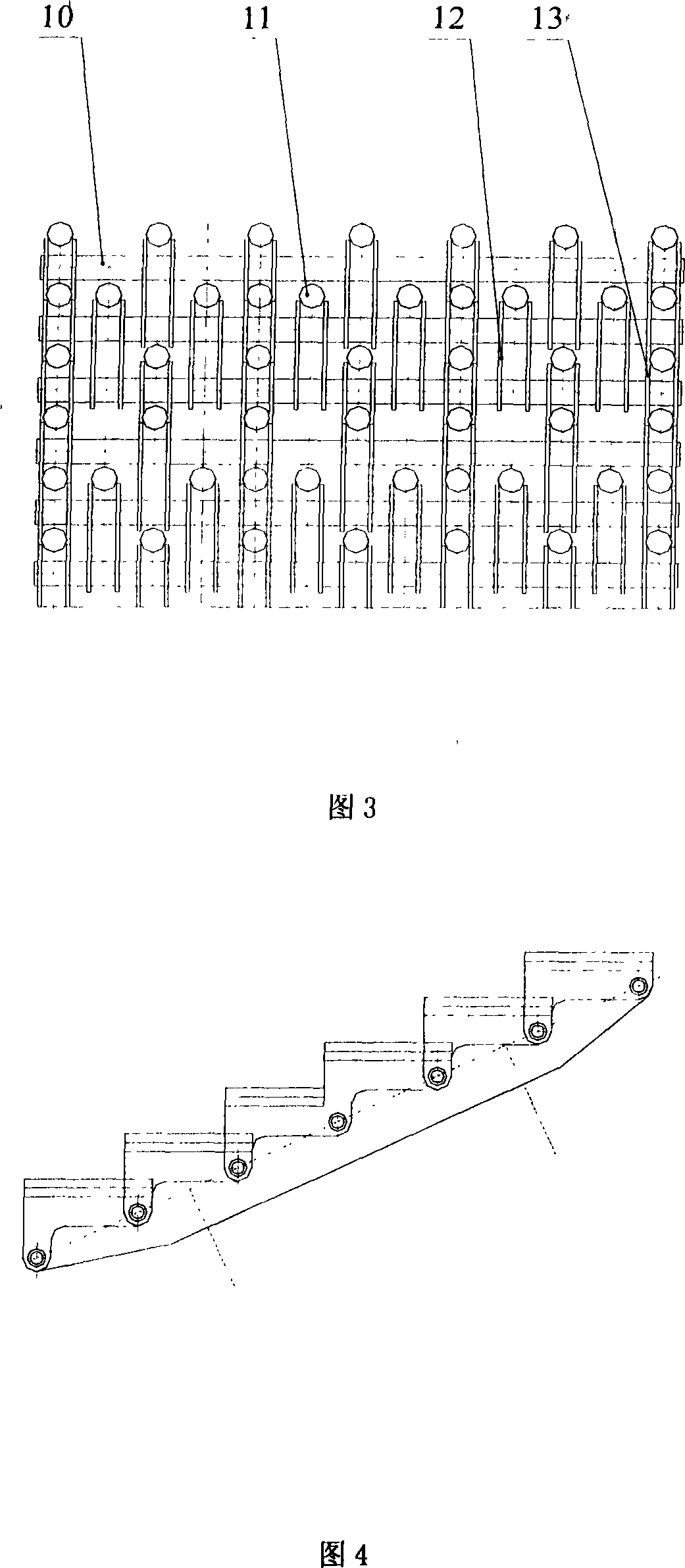

[0013] In Fig. 3 and Fig. 4, the transverse round steel 10 passes through the longitudinal long supporting steel plate 13 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com