Numerically controlled processing method for plane wing rib beam part

A processing method and wing technology, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of easy deformation, difficult clamping, complex structure, etc., and achieve stable processing and surface quality of parts. Satisfaction, reliable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

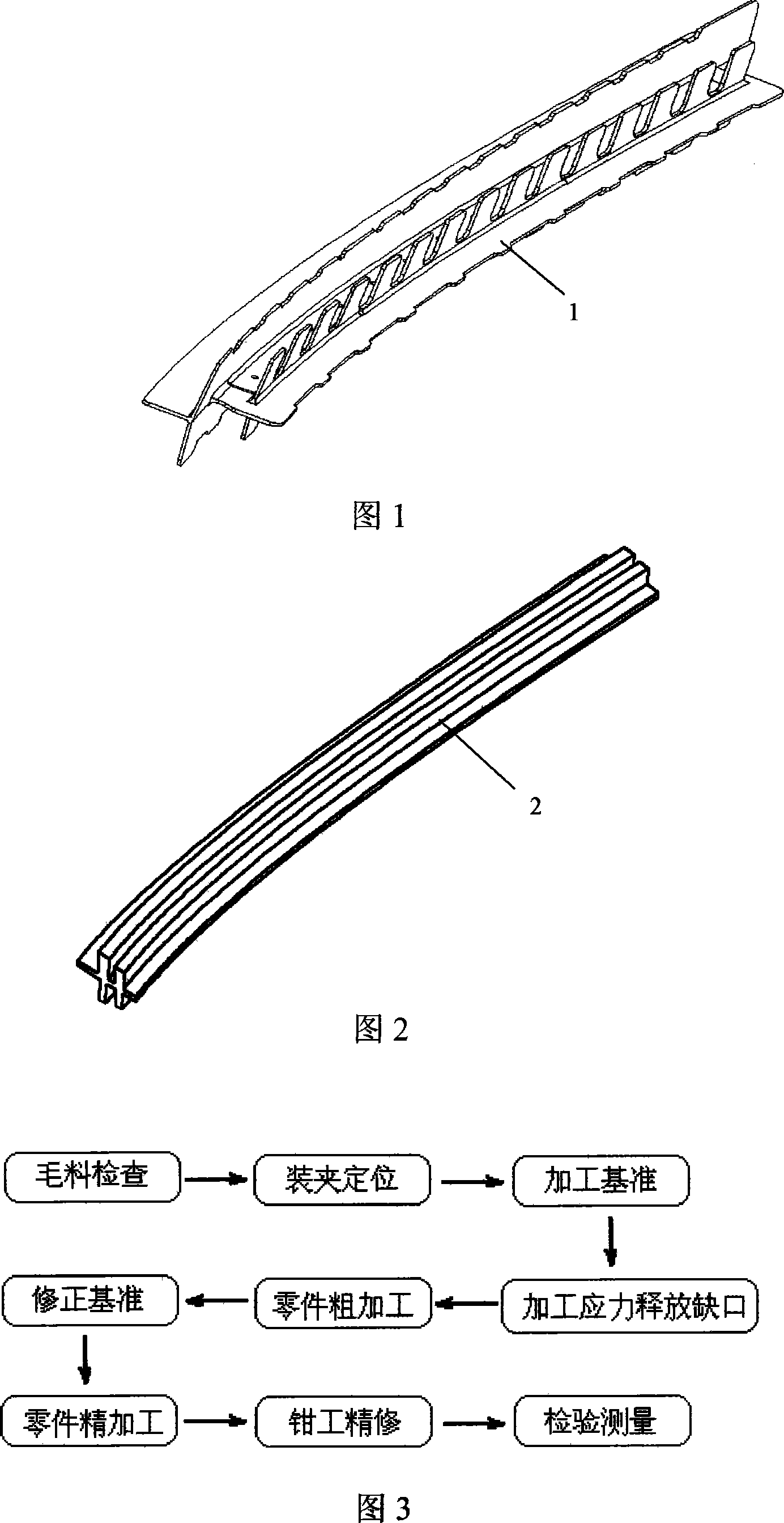

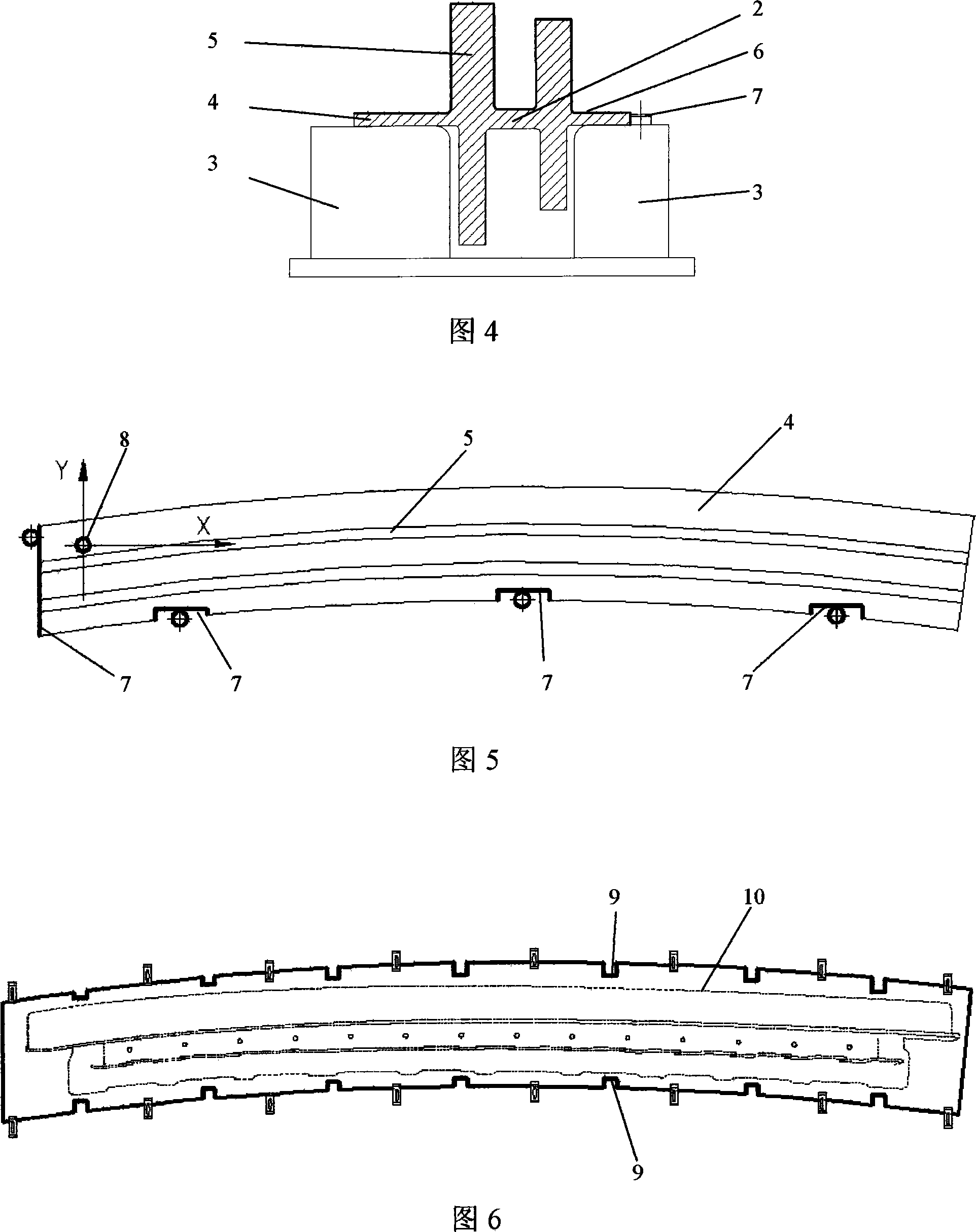

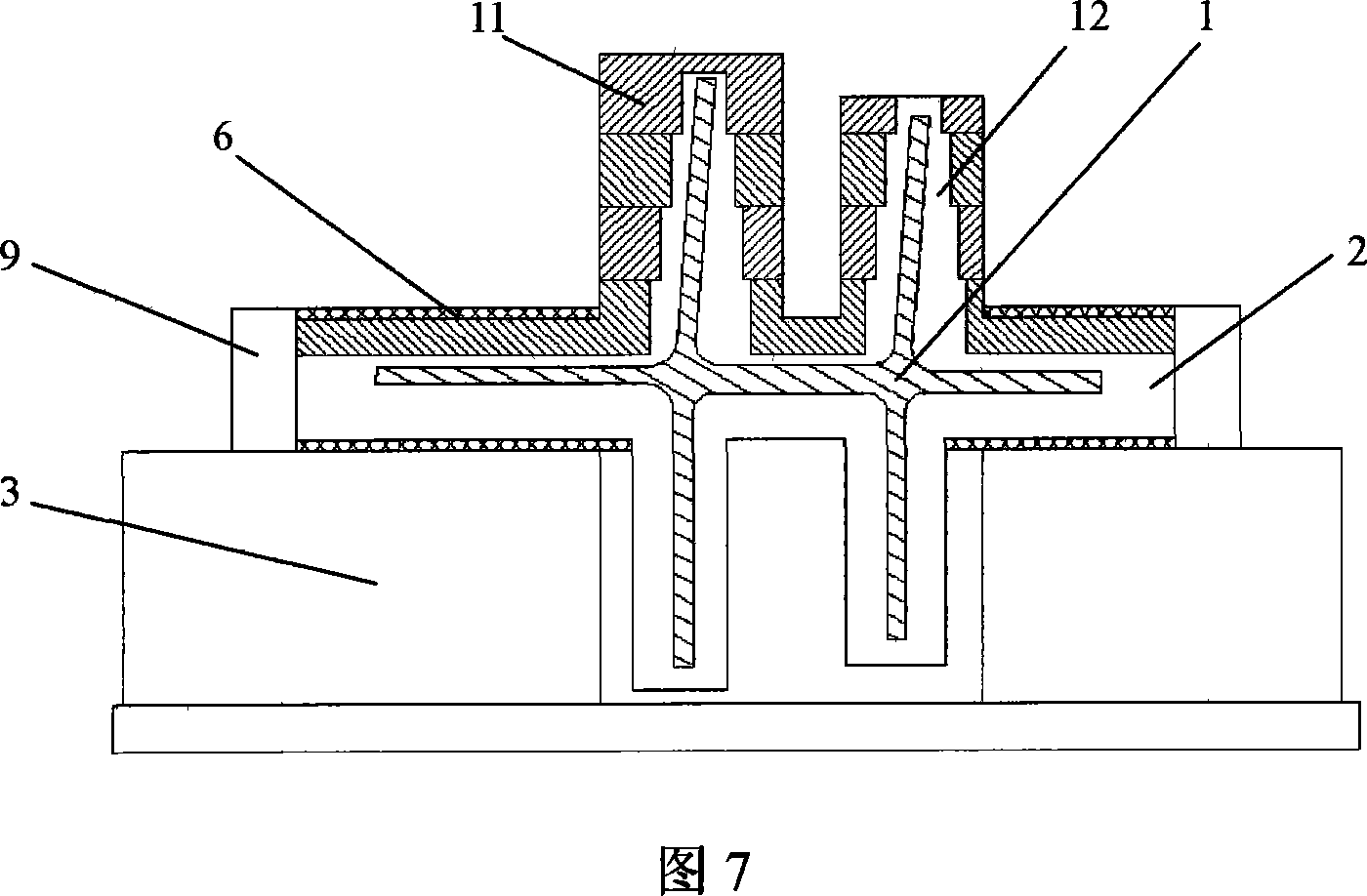

[0019] As shown in Figure 1, the outer dimensions of the aircraft upper edge strip parts are 2300×230×220mm. The main structural features are the double edge plate structure with notches on the web and the bottom, the maximum closed angle is 22.6 degrees, and the height of the edge plate is 72. -95mm, web thickness 5-8mm, edge thickness 5-8mm. Parts processing accuracy requirements: web tolerance ±0.2, edge plate tolerance ±0.2, shape tolerance +0.05 / -0.30, flatness overall length 0.8, edge plate spacing tolerance +0.5 / -0.1, machined surface Ra3.2.

[0020] Processing the profile wool 2 shown in FIG. 1 is a stretch-bending profile, as shown in FIG. 2 , and the section of the profile is a double cross structure. The processing equipment adopts five-coordinate CNC machine tools, which meet the requirements of speed, stroke, swing angle range, spindle power, control system, etc. according to the specific product structure characteristics.

[0021] The processing flow is shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com