Fan blade metal sealing edge and machining method thereof

A technology of a fan blade and a processing method, which is applied in the field of metal edge sealing of fan blades and its processing, can solve the problems of difficult overall deformation control, large overall deformation of the reinforcement edge, large size of the metal reinforcement edge, etc., so as to improve the overall stress relief effect. , Improve product performance, fix and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

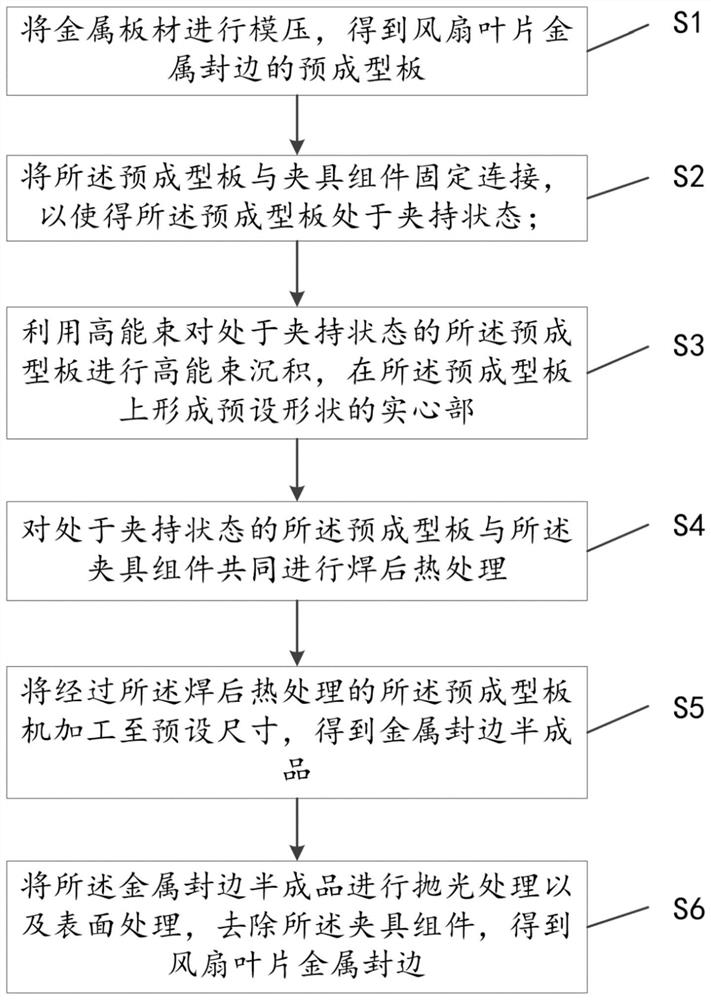

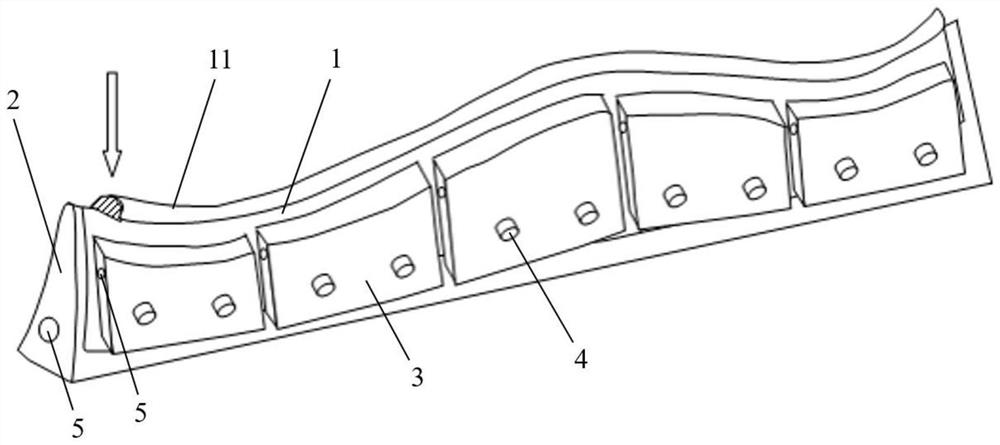

[0042] The present embodiment provides a processing method for metal edge banding of fan blades, such as attached to the instructions Figure 1 As shown, the processing method comprises:

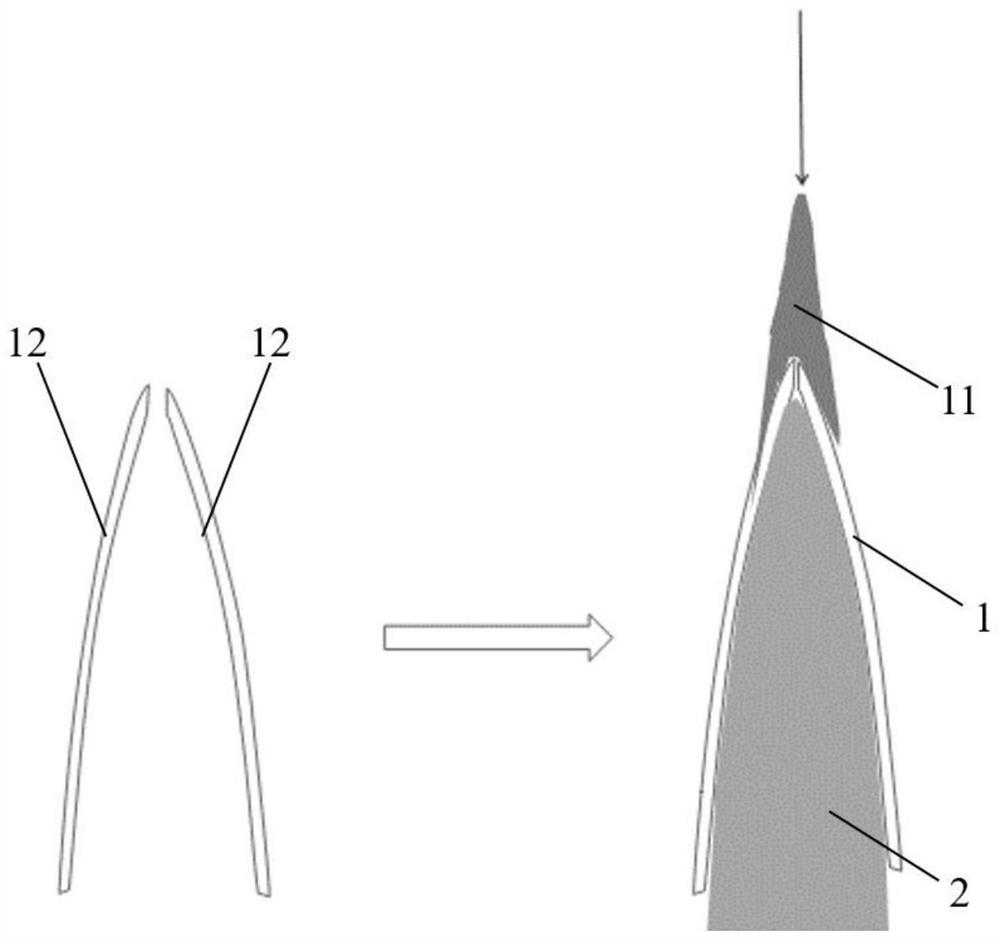

[0043] S1, the metal plate is molded to obtain the preformed plate with metal edge banding of the fan blade;

[0044] S2, the preformed plate and the fixture assembly is fixedly connected so that the preformed plate is in a clamping state; wherein the fixture assembly comprises at least one first conformal fixture and a plurality of second conformal fixtures, the inner side of the preformed plate and the first conformal fixture is fixed by a high-strength adhesive connection, the outer side of the preformed plate and the second conformal fixture is fixed by reinforcing the assembly connection;

[0045] S3, the use of high-energy beams in the clamping state of the preformed plate for high-energy beam deposition, the formation of a preset shape of the solid part of the preformed plate;

[0046] S4, t...

Embodiment 2

[0086] The metal edge banding of the fan blades of the present embodiment is processed by the following processing method:

[0087] The metal sheet is molded to obtain a preformed plate with metal edges of the fan blade;

[0088] The preformed plate is fixed to the first conformal clamp by high-strength adhesive, and the second conformal fixture is fixed to the outside of the preformed plate by screw joint, and then the U-shaped clamp is used to lock, so that the preformed plate is in the clamping state, and the inner and outer surfaces are fully fitted with the clamping assembly;

[0089] At a laser power of 1500W, at a scanning speed of 1000mm / min and a powder delivery rate of 6g / min, the preformed plate is laser deposited to form a solid part of the preset shape on the preformed plate; at the same time, in this process, the pore diameter of the cold flow channel is set to 8mm, where the cold flow is passed through, and the flow rate is greater than 0.5M / s to prevent the tempera...

Embodiment 3

[0095] The metal edge banding of the fan blades of the present embodiment is processed by the following processing method:

[0096] The metal sheet is molded to obtain a preformed plate with metal edges of the fan blade;

[0097] The preformed plate is fixed to the first conformal clamp by high-strength adhesive, and the second conformal fixture is fixed to the outside of the preformed plate by screw joint, and then the U-shaped clamp is used to lock, so that the preformed plate is in the clamping state, and the inner and outer surfaces are fully fitted with the clamping assembly;

[0098] At 1000W of laser power, at a scanning speed of 600mm / min and a powder feeding rate of 4g / min, the preformed plate is laser deposited to form a solid part of the preset shape on the preformed plate; at the same time, in this process, the pore size of the cold flow channel is set to 6mm, where the cold flow is passed through, and the flow rate is greater than 0.5M / s to prevent the temperature fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com