A kind of preparation method of active cooling structure

An active cooling and inner cylinder technology, applied in the field of precision machining, can solve the problems that the geometric dimension accuracy of the inner cooling channel cannot be guaranteed, reduce the processing efficiency of the overall structural components, and increase the processing cost, etc., so as to achieve reliable overall structural performance and ensure geometric shape Consistency, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

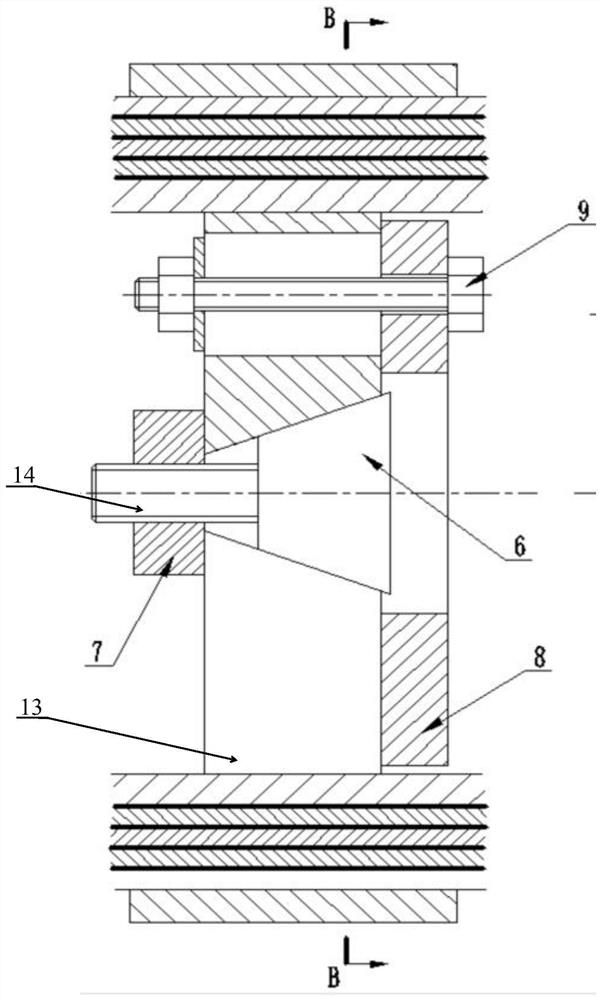

are respectively fixedly connected with the inner support bottom plate 8 through the bottom plate fixing member 9;

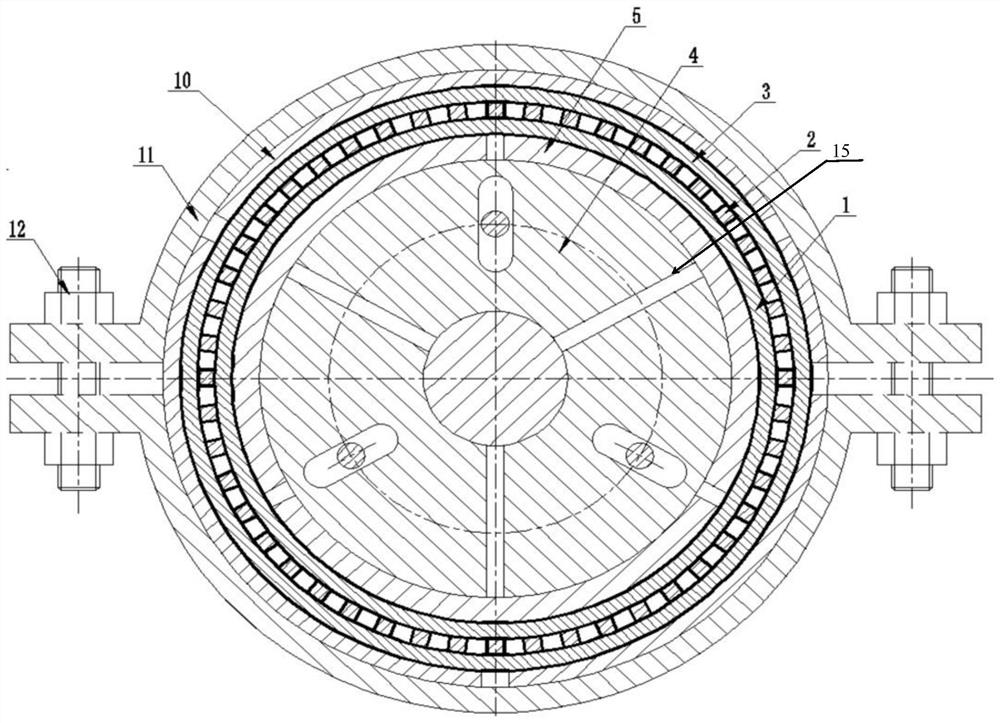

Described shell tooling 11 comprises two symmetrically arranged hoops, and both ends of the hoops are respectively provided with matching clamps

12; The hoop clamps the clamps 12 at both ends of the hoop after the outer cylinder is clamped, respectively.

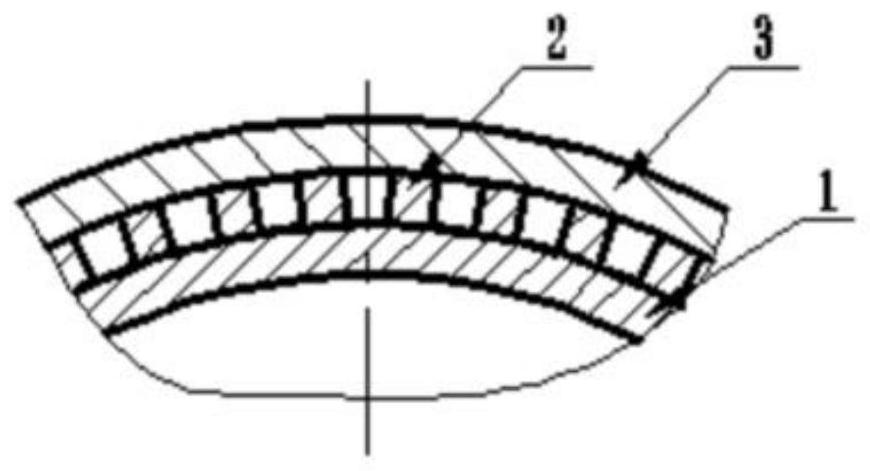

Concretely, described inner support 4 comprises three arc-shaped support blocks 13 enclosing cylindrical supports, arc-shaped support blocks

13 is set in a centrosymmetric manner.

The described adjuster 6 is close to the adjustment hole, and the adjuster 6 adjusts its position in the adjustment hole by the rotation of the fastening bolt 14.

The position of the adjuster 6 changes to adjust the size of the adjustment gap 15 between the arc-shaped support blocks 13.

Further, described paste solder Ni-Li base solder Ni-Li-Gr14B3Si4.5, and contain mass fraction

0.01-0.08% C, the solder melted under capillary ...

Embodiment 1

[0071] 10) Carry out a pressure performance test on the fabricated active cooling structure.

Embodiment 2

[0088] Heating to 700°C at a rate of 180°C / h for 20min;

[0089] Heating to 900°C at a rate of 360°C / h for 120min;

[0090] Heating to 1020°C at a rate of 500°C / h, brazing at 1020°C ± 5°C, and holding for 30min;

[0091] The cooling procedure after brazing is: cooling to 700°C at a rate of 240°C / h, followed by vacuum cooling in the furnace to 200°C for filling

[0094] 10) Carry out a pressure performance test on the fabricated active cooling structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com