Method and device for protecting metal surface from corroding and scaling

A technology for metal surfaces and metal parts, which is applied in the field of protecting metal surfaces from corrosion, scaling and devices, and can solve problems such as limited protection range, easy peeling off of the protective layer, and loss of protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

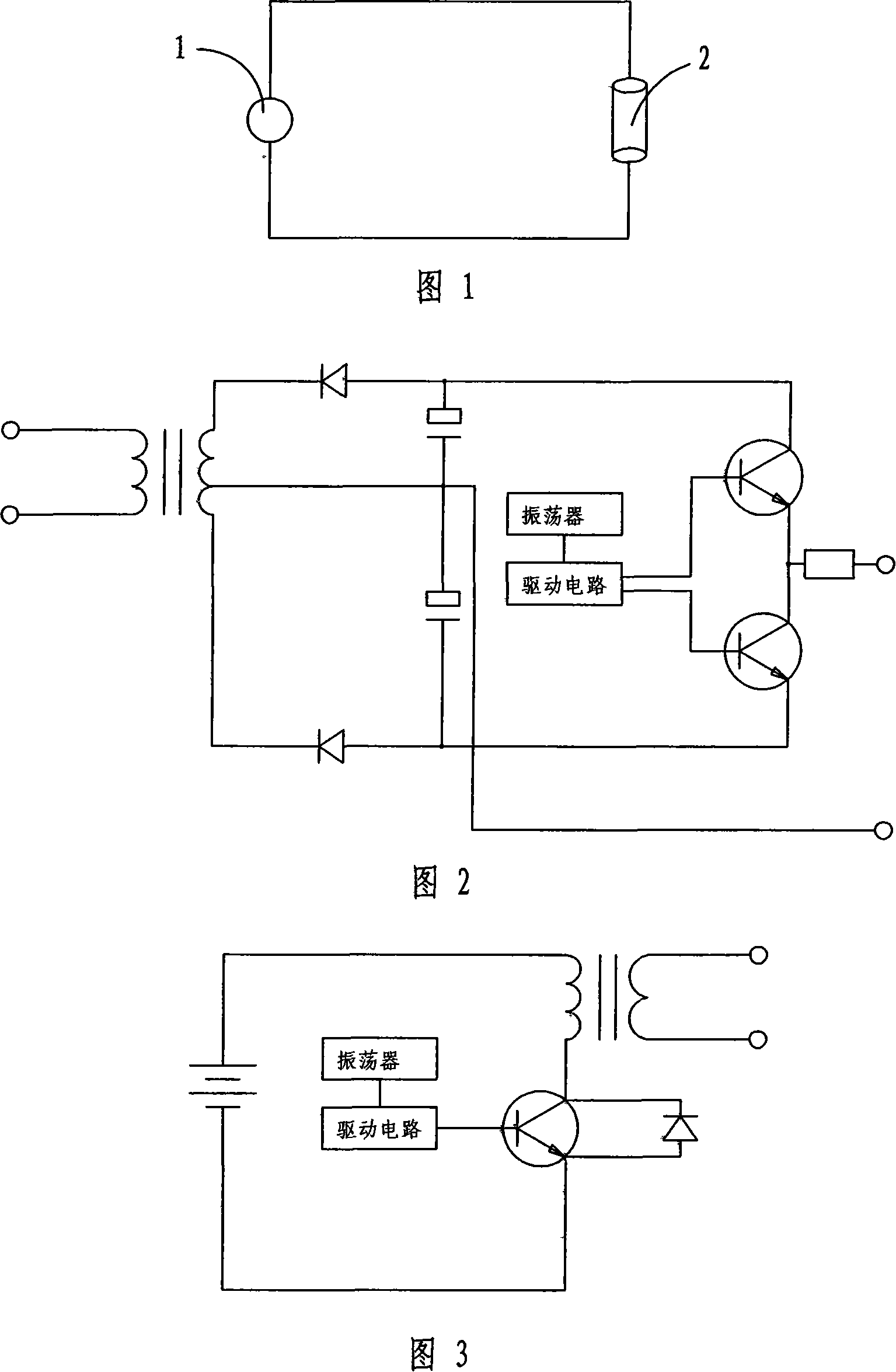

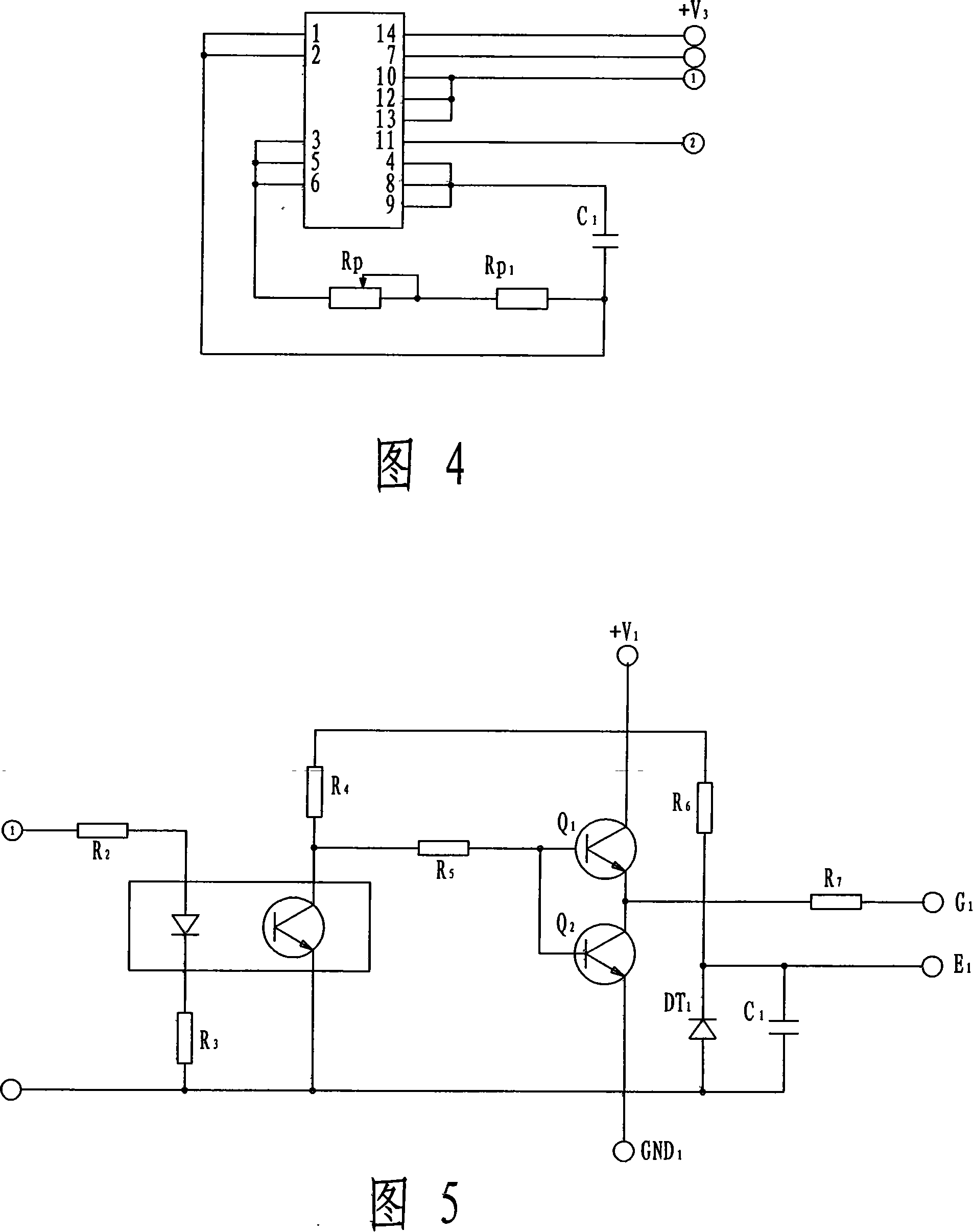

Method used

Image

Examples

Embodiment 1

[0022] In multiple identical pools [500mm×500mm×500mm], multiple metal parts 1 with the same steel pipe structure are placed respectively, with a length of 250mm, a diameter of 50mm, and a wall thickness of 3mm. The pools are filled with saturated salt water, and one of them does not take any measures. Two steel pipes are anti-corrosion by this method, the frequency of the AC power supply 2 connected to one of them is 2kHz, and the current density passing through the steel pipe is 2A / m 2 , the frequency of the other connected AC power supply 2 is 200Hz, and the current density through the steel pipe is 0.8A / m 2 , the frequency of another connected AC power supply 2 is 50Hz, and the current density through the steel pipe is 0.5A / m 2 , and the frequency of the connected AC power supply 2 is 1kHz, and the current density through the steel pipe is 1A / m 2 , the frequency of another connected AC power supply 2 is 4kHz, and the current density through the steel pipe is 10A / m 2 , th...

Embodiment 2

[0024] Inject water multiple times into two identical boiler containers, one of which does not take any measures, and the metal parts 1 of multiple boiler container structures adopt this method for anti-scaling, and the frequency of the AC power supply 2 connected to one of them is 2kHz, The current density through the boiler vessel is 2A / m 2 , the frequency of the other connected AC power supply 2 is 200Hz, and the current density passing through the boiler container is 0.8A / m 2 , the frequency of another connected AC power supply 2 is 50Hz, and the current density passing through the boiler container is 0.5A / m 2 , and the frequency of a connected AC power supply 2 is 1kHz, and the current density passing through the boiler container is 1A / m 2 , the frequency of another connected AC power supply 2 is 4kHz, and the current density passing through the boiler container is 10A / m 2 , the frequency of another connected AC power supply 2 is 3kHz, and the current density passing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com