Electric baking dish

An electric roasting and pan body technology, applied in the field of roasting appliances, can solve the problems of large thermal lag, short thermal radiation transfer distance, slow temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

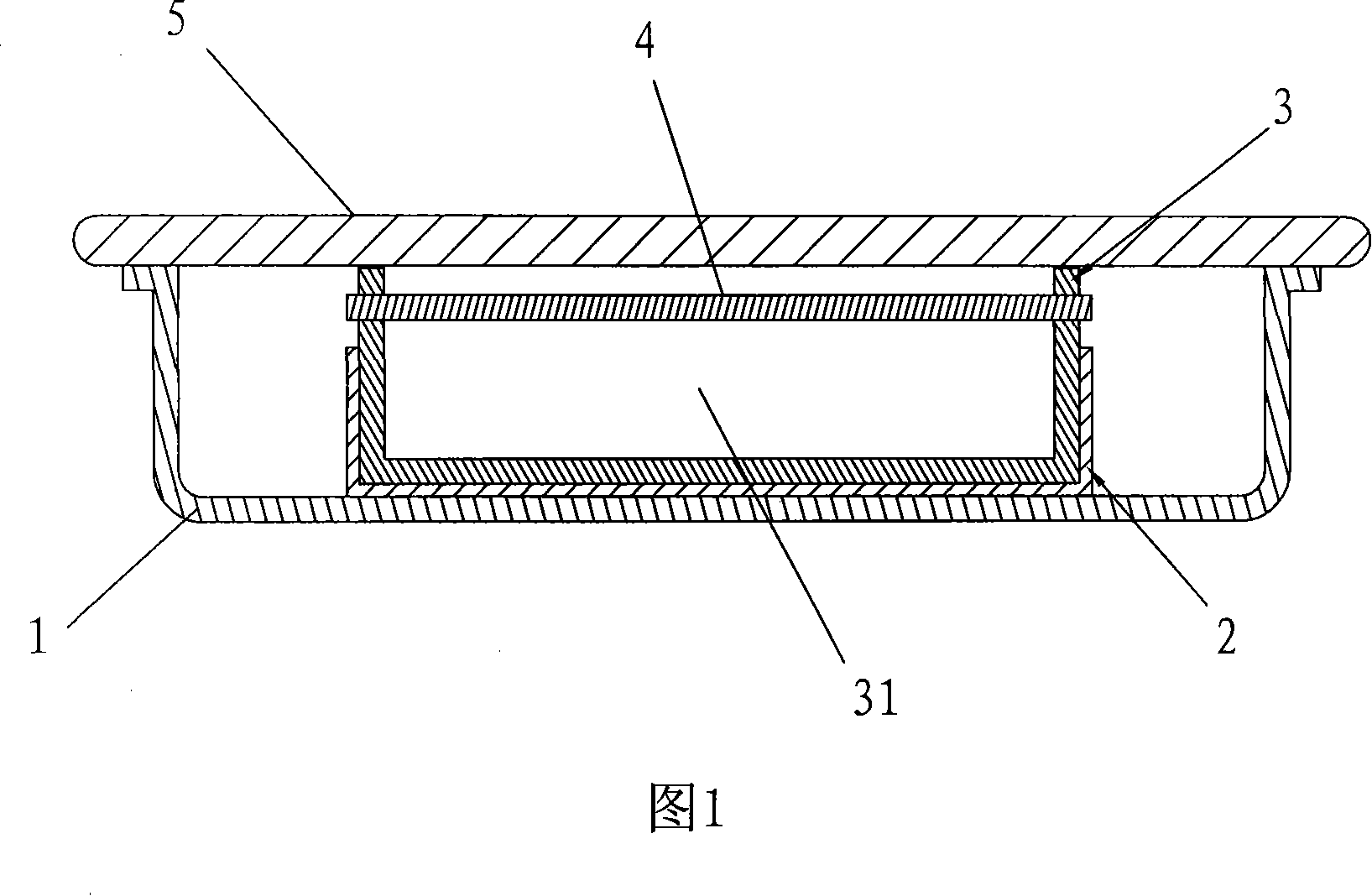

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] As shown in Figure 1, an electric baking tray includes a base body 1, a disc body 5 and a control device, the disc body 5 is fixedly connected with the base body 1, the disc body 5 is a light-transmitting glass-ceramic plate, and includes carbon fiber Quartz electric heating tube 4, a hollow insulating and heat-insulating light-shielding body 3 with an upper opening and a base 2, the bottom of the insulating and heat-insulating light-shielding body 3 is installed in the base 2, and several carbon fiber quartz electric heating tubes 4 are installed on the insulating, heat-insulating and light-shielding body. In the inner cavity 31 of the body 3; the base 2 is fixed in the seat body 1, the upper end of the insulating and heat-insulating light-shielding body 3 is closely matched with the disc body 5, and the corresponding part of the disc body 5 and the upper openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com