Method monitoring termination detecting state

A technology of endpoint detection and status, which is applied in the control of workpiece feed movement, grinding machine parts, semiconductor/solid-state device manufacturing, etc., can solve the problems of product grinding, unsafe production line, and no one is very good, so as to reduce the Cost, the effect of ensuring product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the current semiconductor production process, it is very important to ensure that the endpoint detection system is in a normal state.

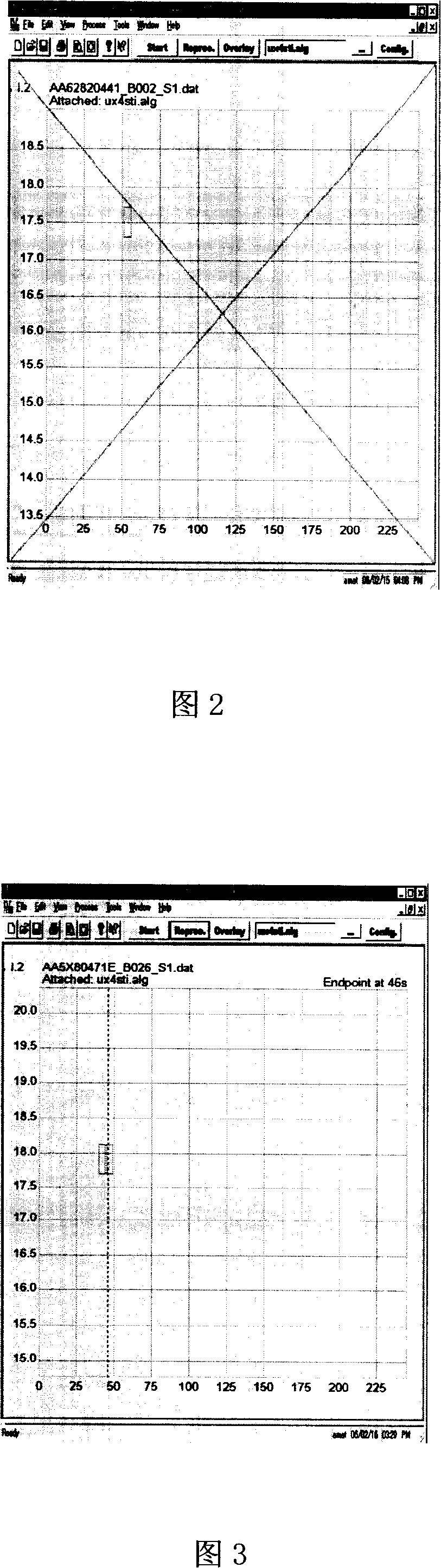

[0018] The present invention pre-generates a light sheet with the same structure as the product to be produced as a test piece, and uses the same end point detection program as the product to detect the end point of the light sheet before producing a grinding process product that requires end point detection. The slice has no pattern, so it is easier to reflect the intensity of the detected optical signal change. So as to achieve the purpose of monitoring whether the endpoint detection is in a normal state.

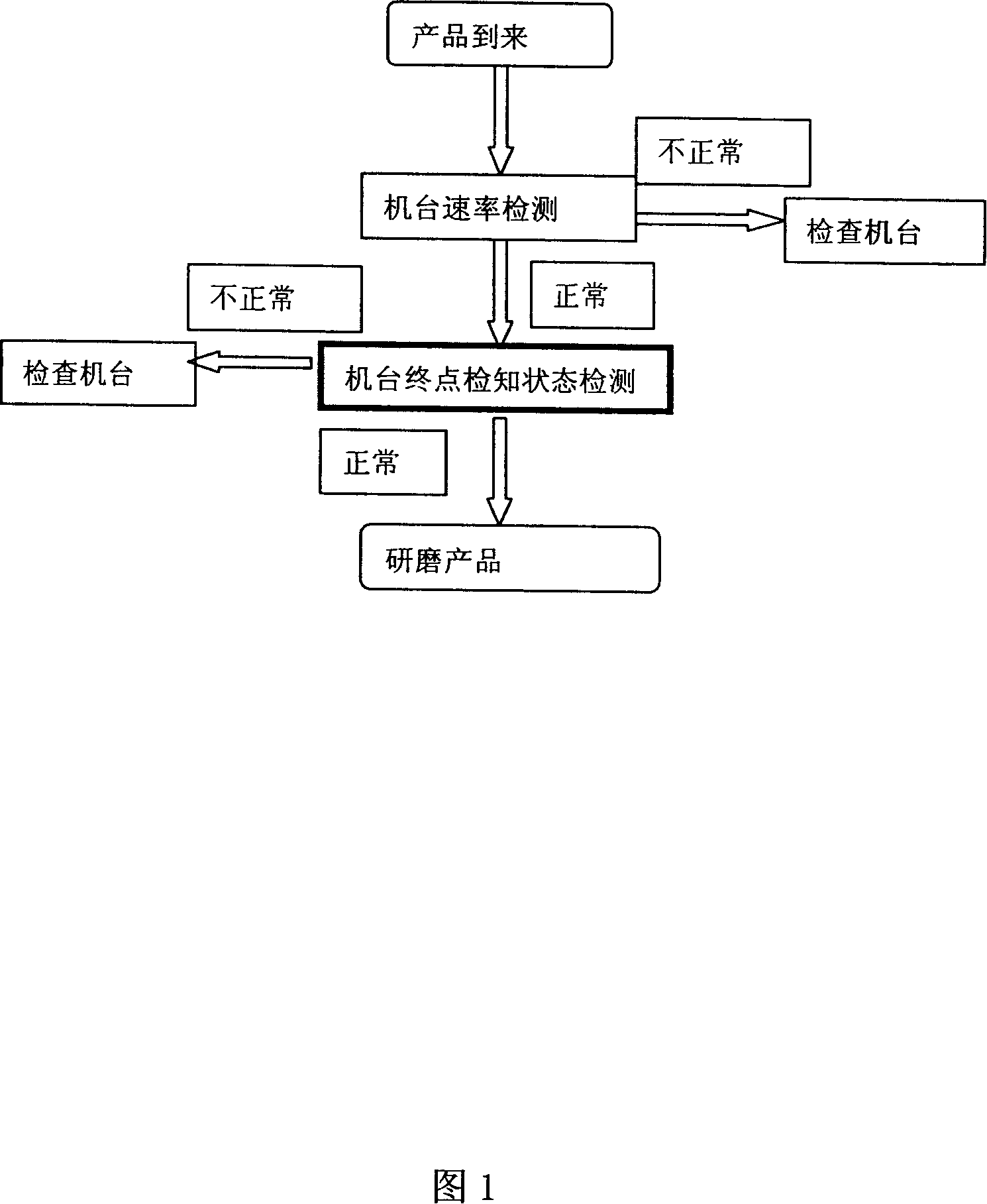

[0019] The flow chart shown in FIG. 1 specifically describes how to implement the process of monitoring whether the end point detection of chemical mechanical polishing is normal or not by using the method of the present invention.

[0020] When a batch of products arrives and needs to be ground, first check whether the speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com