Injection molding nozzle with filter

A filter device and nozzle technology, applied in the field of nozzles, can solve problems such as inability to filter impurities, poor control of product quality, and no filter device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

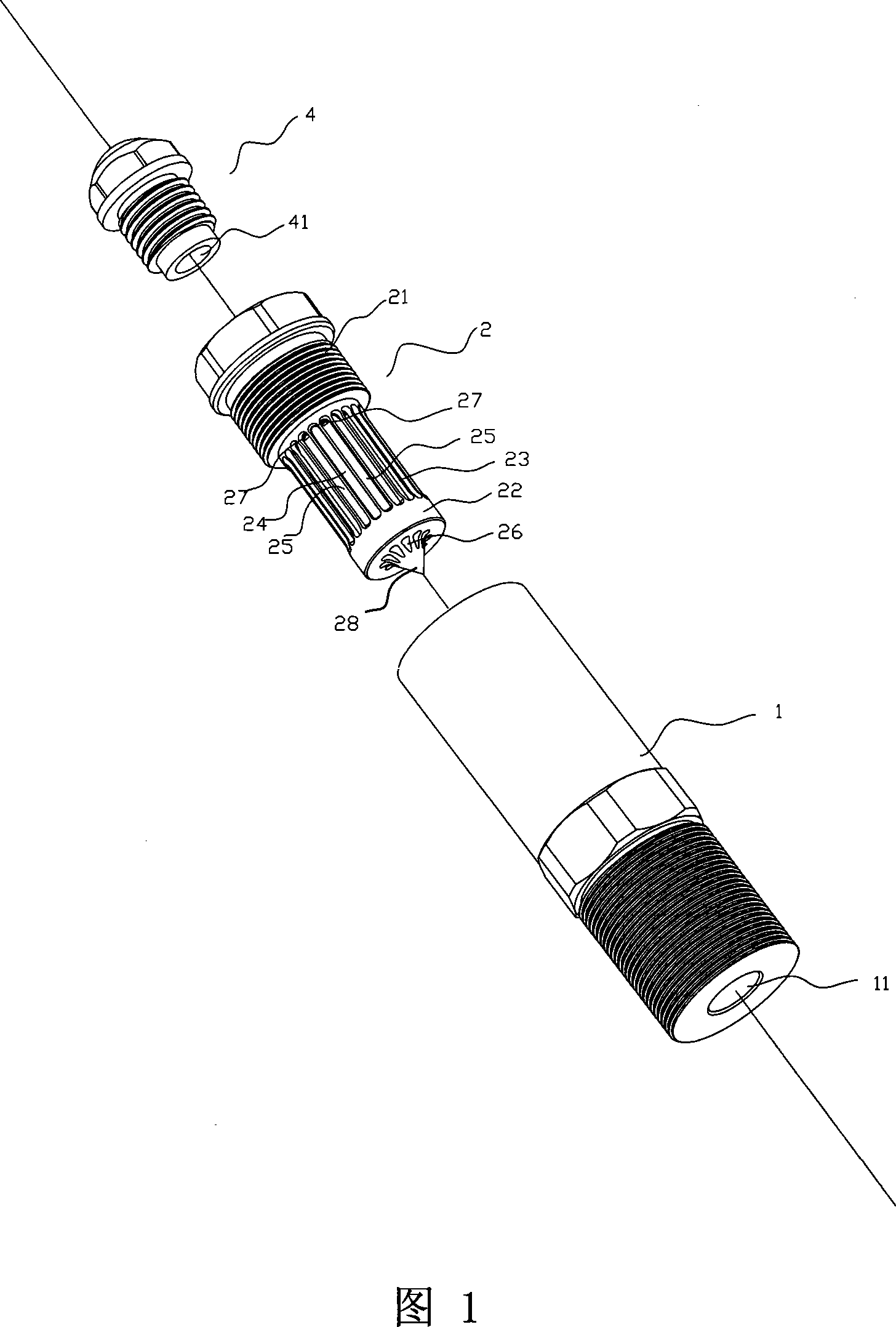

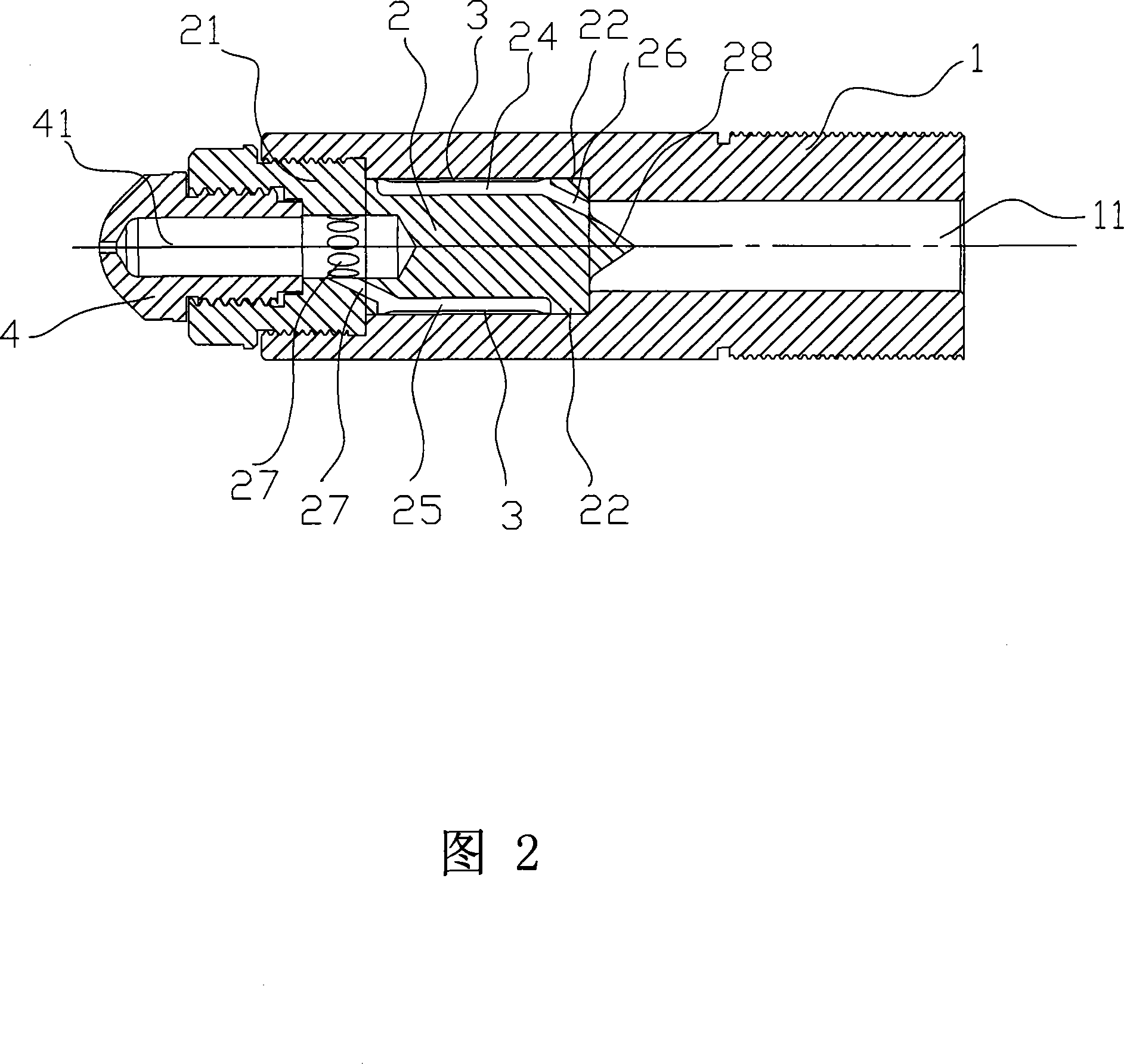

[0010] As shown in Fig. 1 and Fig. 2, the injection nozzle with filtering device has a nozzle nozzle base 1 connected with the barrel of the main engine, an injection channel 11 is provided in the nozzle nozzle holder, and a filter device 2 is built in the nozzle nozzle holder 1. The rear part 21 of the filter device 2 is threadedly connected and fixed to the nozzle socket 1, wherein the outer edge 22 of the front end of the filter device 2 and the inner channel 11 of the nozzle socket 1 are sealed and fitted, and the outer diameter of the middle part 23 of the filter device 2 is smaller than that of the filter device. 2 The outer diameter of the outer edge 22 of the front end, thus forming a filter gap 3 between the nozzle socket 1 and the filter device 2, and a plurality of feed grooves 24 and discharge grooves 25 are arranged on the outer wall of the middle part 23 of the filter device , Feed chute 24 and discharge chute 25 are arranged at intervals. A plurality of feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com