Intelligent heat preserving and freezing protecting technology for heat exchanger

A heat exchanger and plate heat exchanger technology, applied in damage protection, lighting and heating equipment, refrigeration components, etc. The effect of preventing heat exchanger damage, preventing environmental low temperature and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

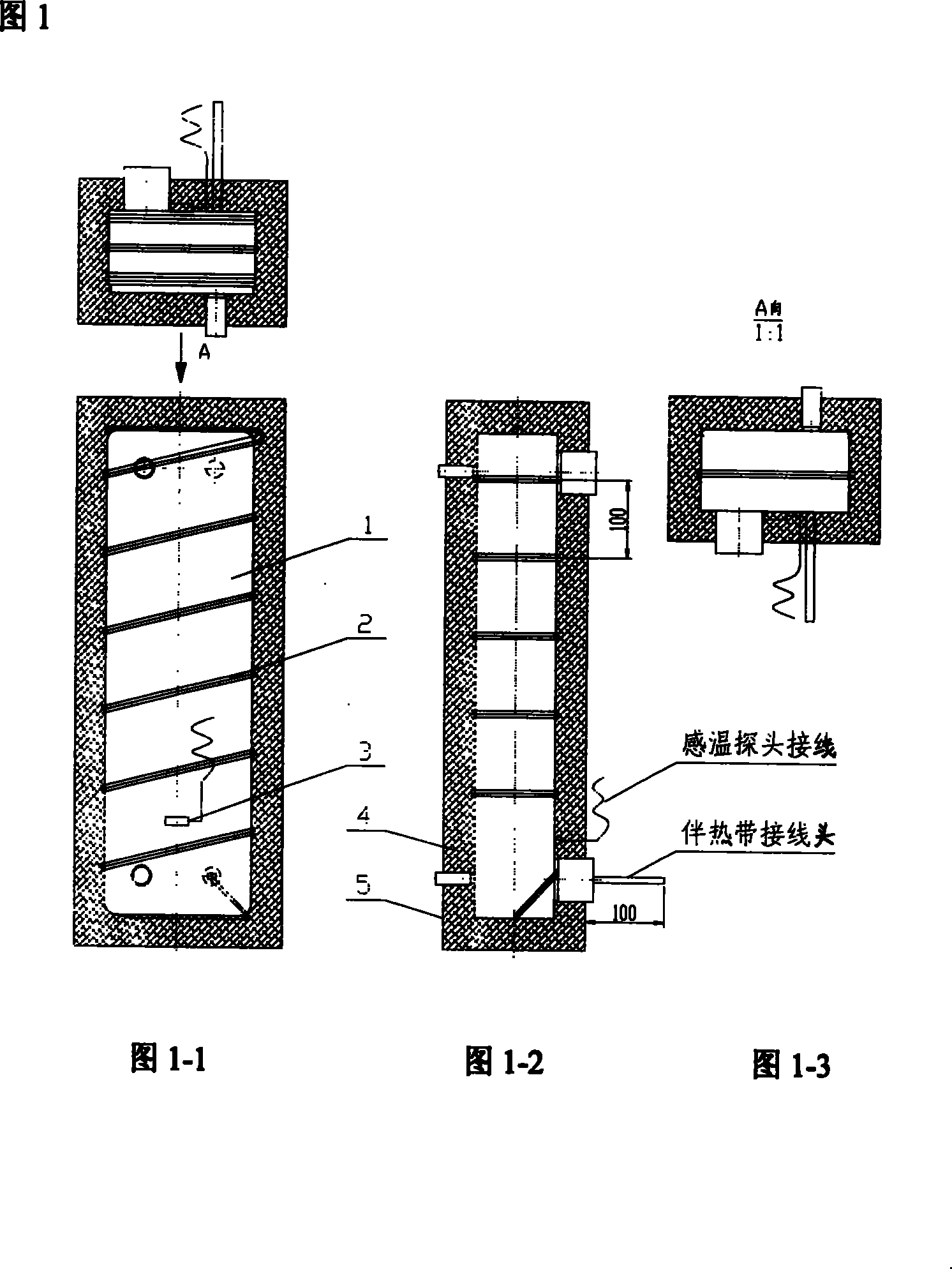

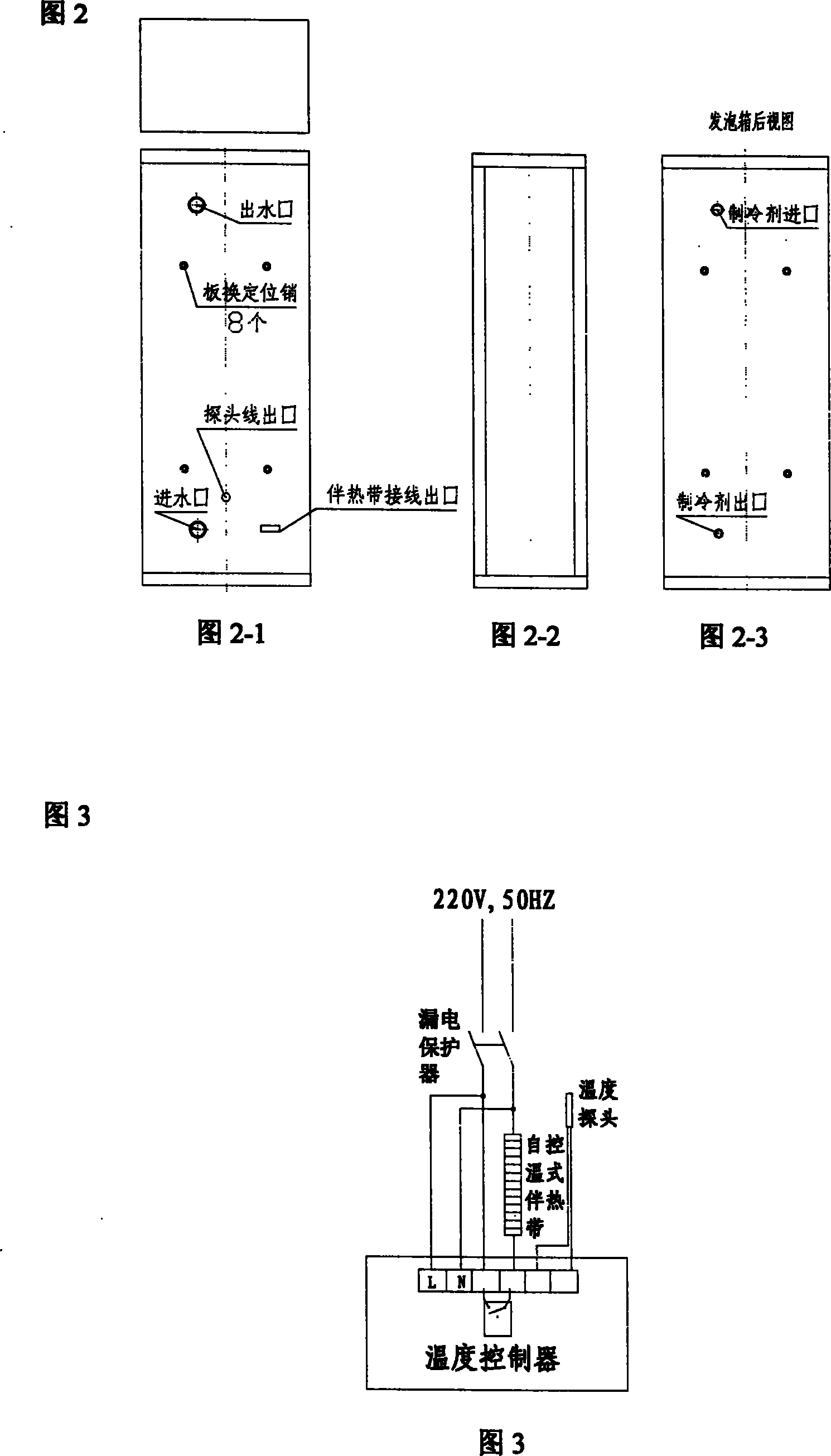

[0018] An embodiment of the present invention will be illustrated below in conjunction with Fig. 1-1 to Fig. 3, and will be described in detail so that those skilled in the art can more easily understand the features and functional characteristics of the present invention, rather than to limit the scope of the present invention.

[0019] According to the method of the present invention, the steps of the intelligent heat preservation and antifreeze implementation method for plate heat exchangers include:

[0020] a: Wind the heating cable (2) of the corresponding length obtained from the calculation and experimental results on the surface of the heat exchanger according to the calculated spacing of 100 mm, and stick the heating cable (2) to the surface of the heat exchanger (1) with adhesive tape;

[0021] b: Fix the temperature probe (3) at the middle and lower part of the surface of the heat exchanger (1);

[0022] c: The foam (4) on the surface of the heat exchanger (1) is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com