Flatness checking device and method of using the same

A flatness detection and balancing arm technology, applied in the field of flatness devices, can solve problems such as low accuracy, time-consuming measurement of large-size planes, and high operator requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

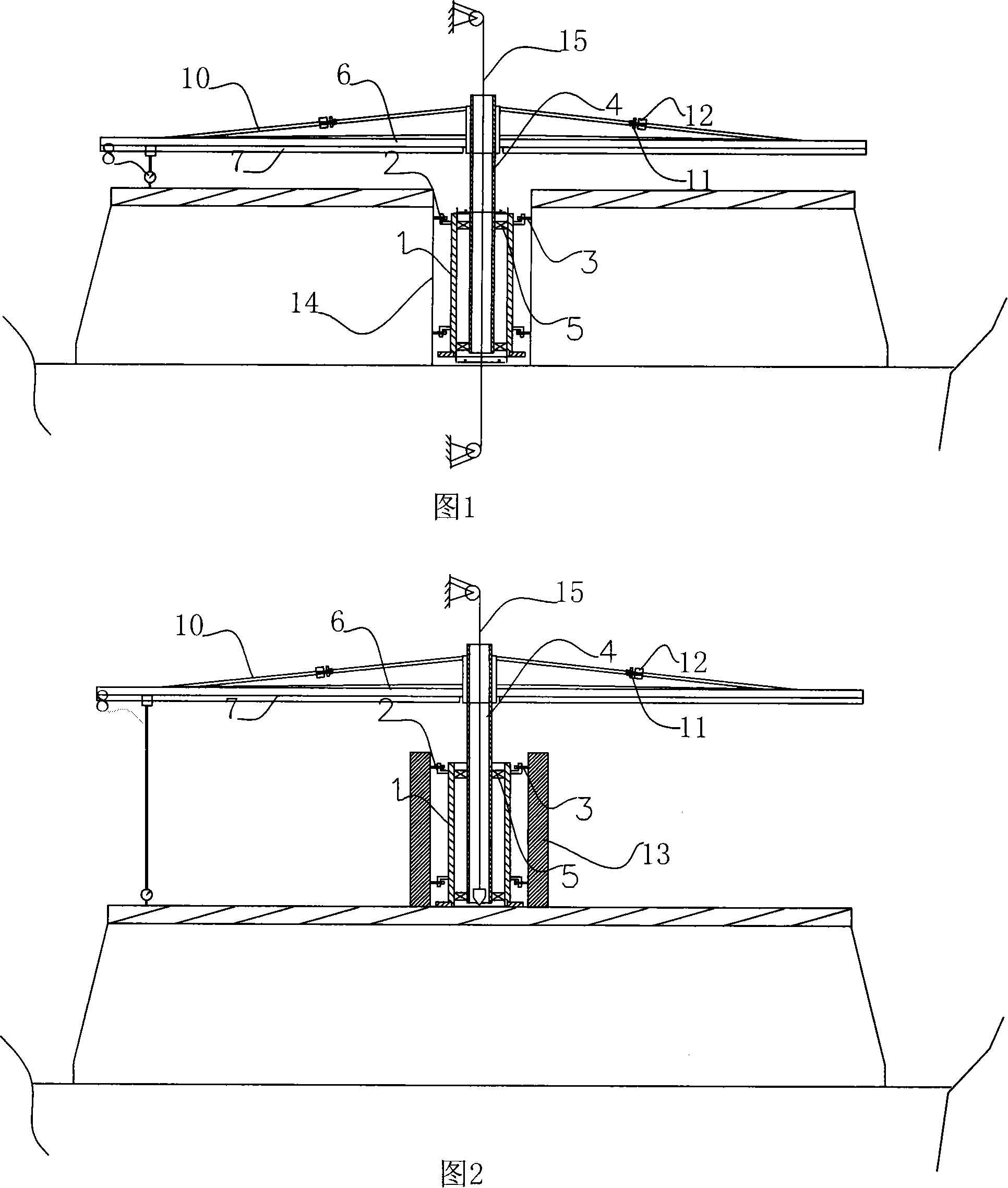

[0015] Embodiment 1, as shown in Figure 1, a flatness detection device and a method for measuring the flatness of a large plane with a central hole, its detection device includes a seat cylinder 1, and the side of the seat cylinder 1 has a lug plate 2, The lug plate 2 is provided with an adjusting bolt 3 screwed on it by a thread, a shaft rod 4 is arranged in the seat cylinder 1, and the shaft rod 4 is fixed in the seat cylinder 1 through a bearing 5, and its upper end has a balance arm 6 extending to both sides. , the balance arm 6 is perpendicular to the shaft rod 4, and its bottom is a straight guide rail 7 with high flatness, the guide rail 7 is perpendicular to the shaft rod 4, and the guide rail 7 is equipped with a dial indicator 8 that can slide on it.

[0016] During measurement, a line 15 perpendicular to the ideal plane of the measured plane is drawn at the center of the central hole 14 as a reference line (the ideal plane is horizontal, and the reference line can be...

Embodiment 2

[0021] Embodiment 2, as shown in Figure 2, a flatness detection device and a method for measuring the flatness of a large plane without a central hole, its detection device includes a seat cylinder 1, and the side of the seat cylinder 1 has a lug plate 2, The lug plate 2 is provided with an adjusting bolt 3 screwed on it by a thread, a shaft rod 4 is arranged in the seat cylinder 1, and the shaft rod 4 is fixed in the seat cylinder 1 through a bearing 5, and its upper end has a balance arm 6 extending to both sides. , the balance arm 6 is perpendicular to the shaft rod 4, and its bottom is a straight guide rail 7 with high flatness. The guide rail 7 is perpendicular to the shaft rod 4, and the guide rail 7 is equipped with a dial indicator 8 that can slide on it.

[0022] When measuring, first fix an auxiliary cylinder 13 on the measured plane, and draw a line 15 perpendicular to the ideal plane of the measured plane at the center of the auxiliary cylinder 13 as a reference lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com