Device for testing and analyzing warehouse separated type denitrated catalyzer

A denitration catalyst, testing and analysis technology, which is applied in the field of SCR denitration catalyst sampling, analysis and detection devices in power plants, can solve the problems of poor comparability of test results, long interval time, long time consumption, etc., and achieves the effect of saving analysis and testing time and increasing comparability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

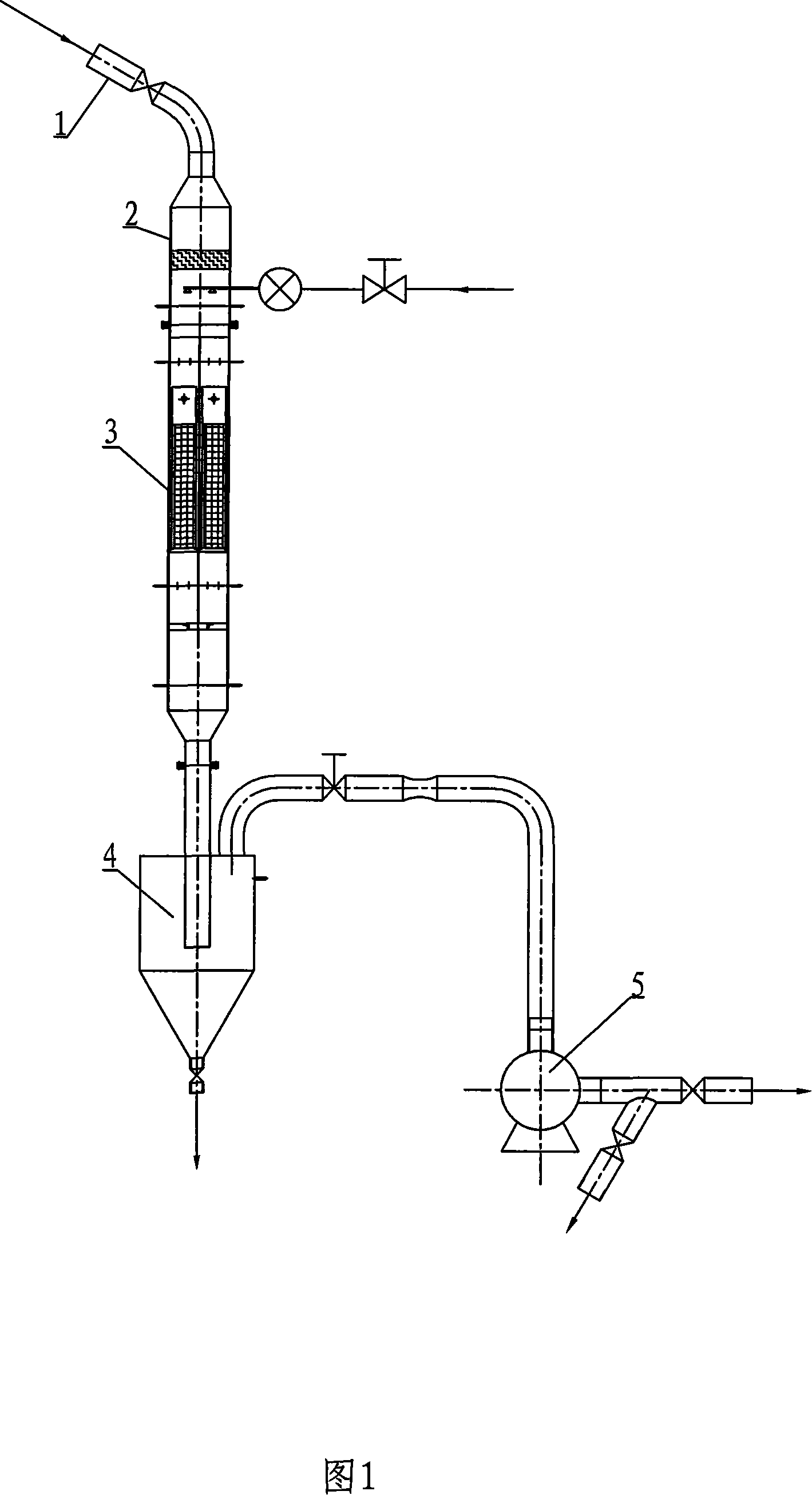

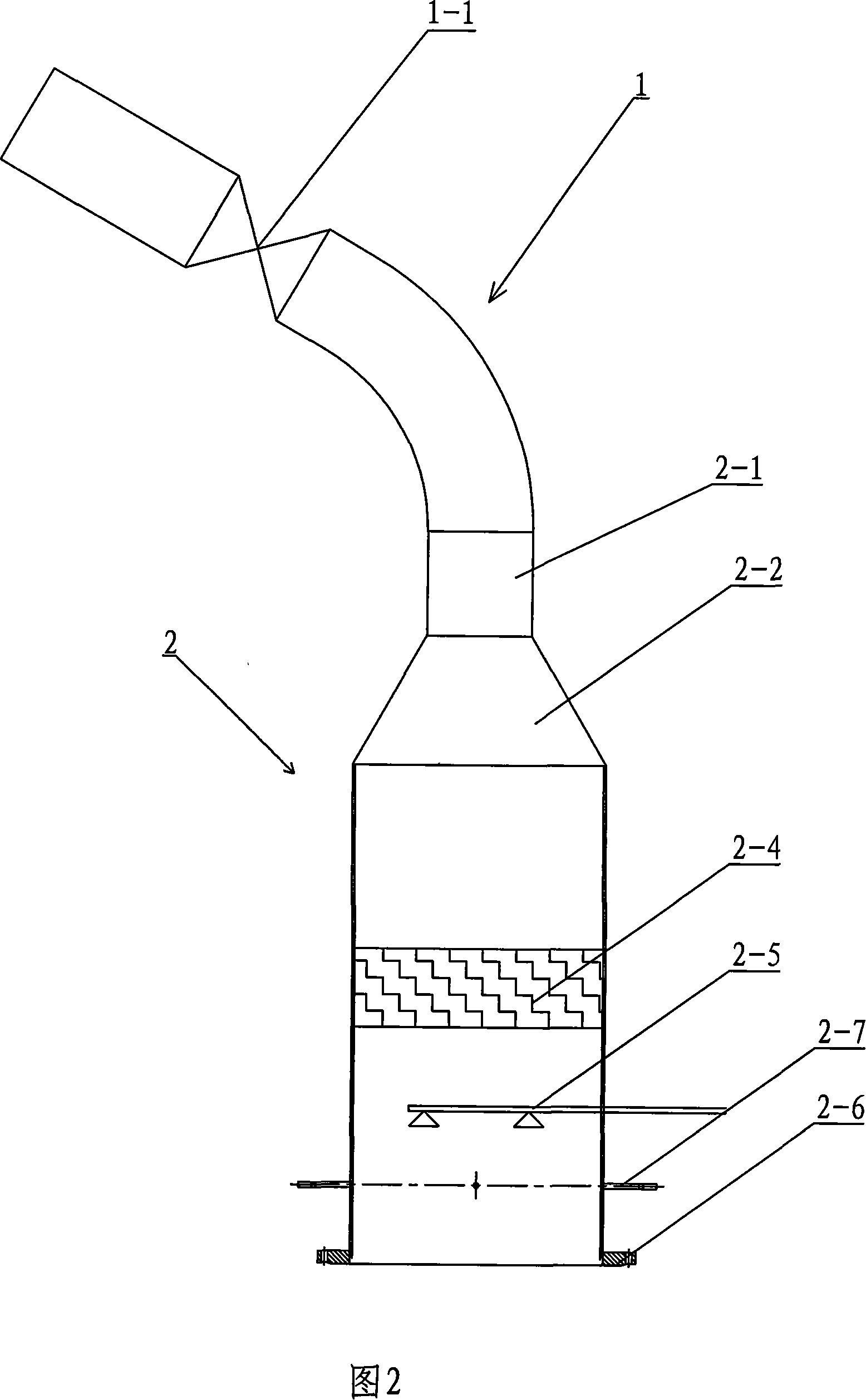

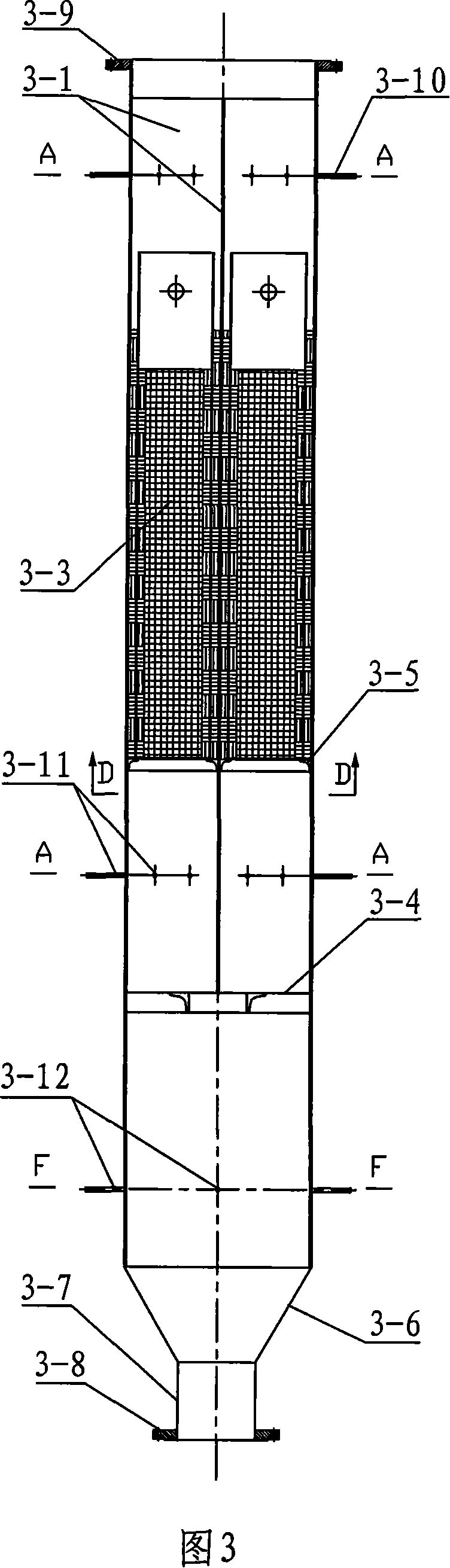

[0035] Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5. The denitrification catalyst test and analysis device with compartments consists of a flue gas introduction pipe 1, a flue gas mixing component 2, an air induction device 5, and a flue gas purification component 4. A sub-compartment test reactor 3 is arranged between the flue gas mixing component 2 connected with the flue gas introduction pipe 1 and the flue gas purification component 4 connected with the air induction device 5, and the sub-compartment test reactor 3 mixes the flue gas The component 2 communicates with the flue gas purification component 4, and the inner cavity of the sub-compartment test reactor 3 is divided into four cavities 3-2 by the sub-compartment plate 3-1, and a Catalyst basket 3-3, put sub-chamber plate 3-1 in sub-chamber type test reactor 3 through sub-chamber plate s...

Embodiment 2

[0043] Please refer to Fig. 4, Fig. 5, Fig. 6, Fig. 7, Fig. 8, Fig. 9, and Fig. 10. For power plants without SCR reactors, the candidate catalysts are compared. The nozzle 2-1 of the ammonia gas metering injection system extends into the upper end of the flue gas mixing assembly 2, and a static mixer 3-9 is welded under the support frame of the compartment plate in the sub-chamber test reactor 3. The static mixer The downstream pressure measurement and sampling port 3-10 is set up below, and the flue gas is drawn from a suitable temperature range between the economizer and the air preheater. When the temperature is too high or too low, exceeding the operating range of the catalyst module, shut down the reaction test system.

[0044] In the absence of an SCR denitration reactor, ammonia gas needs to be sprayed in order for the denitration reaction to occur in the denitration catalyst module. The amount of ammonia injection needs to be adjusted and controlled according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com