Method for implementing variable air quantity zone control and system frame thereof

A technology of partition control and system framework, applied in cooling/ventilation/heating renovation, instruments, electrical and digital data processing, etc., it can solve the problems of excessively uniform cooling air flow and insufficient control of air volume in the slot, so as to reduce the speed and improve the heat dissipation. Efficiency, the effect of reducing system noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

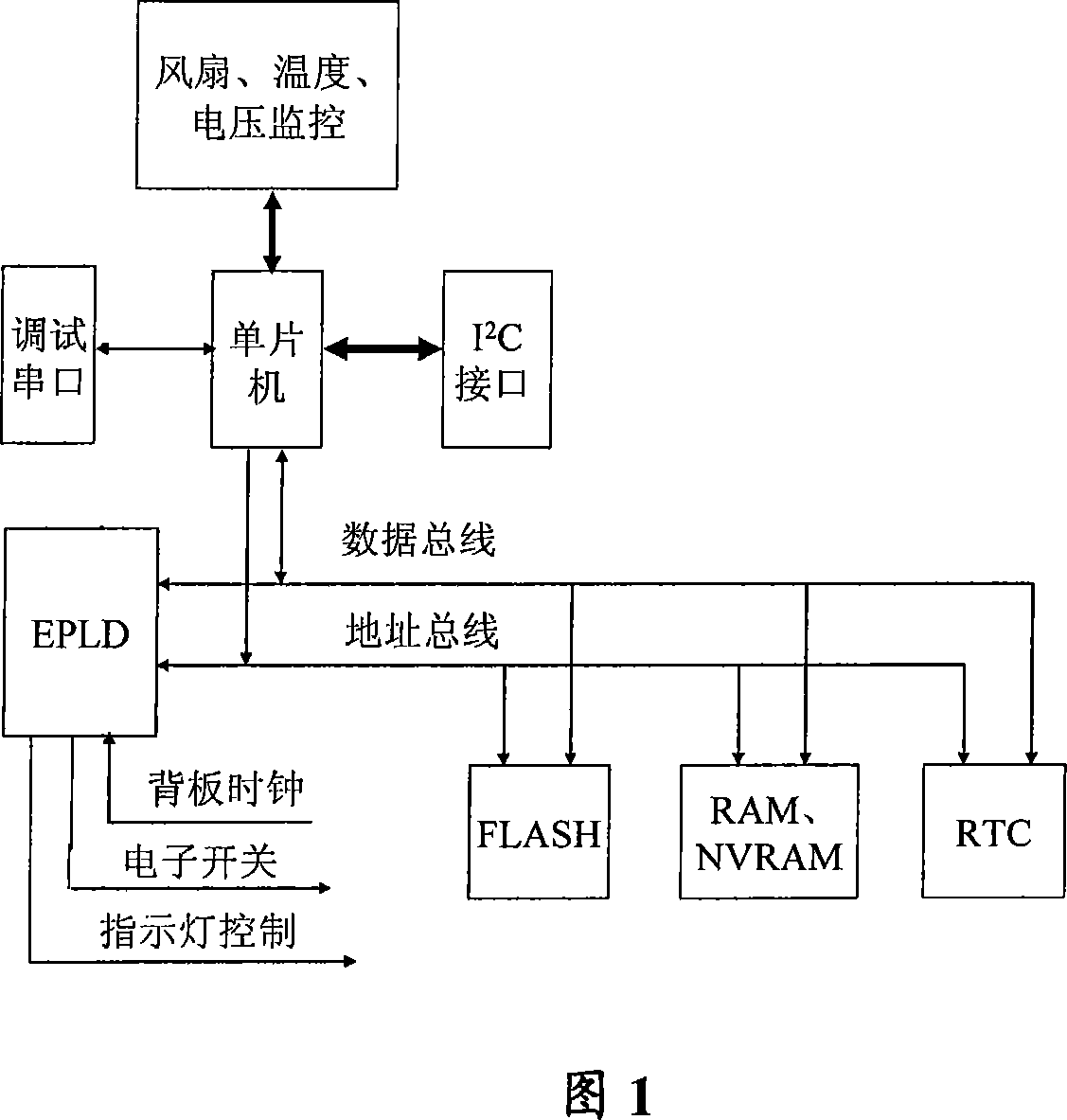

[0036] The present invention provides a method for variable air volume zone control and a system framework for applying the method. The system framework includes the following modules:

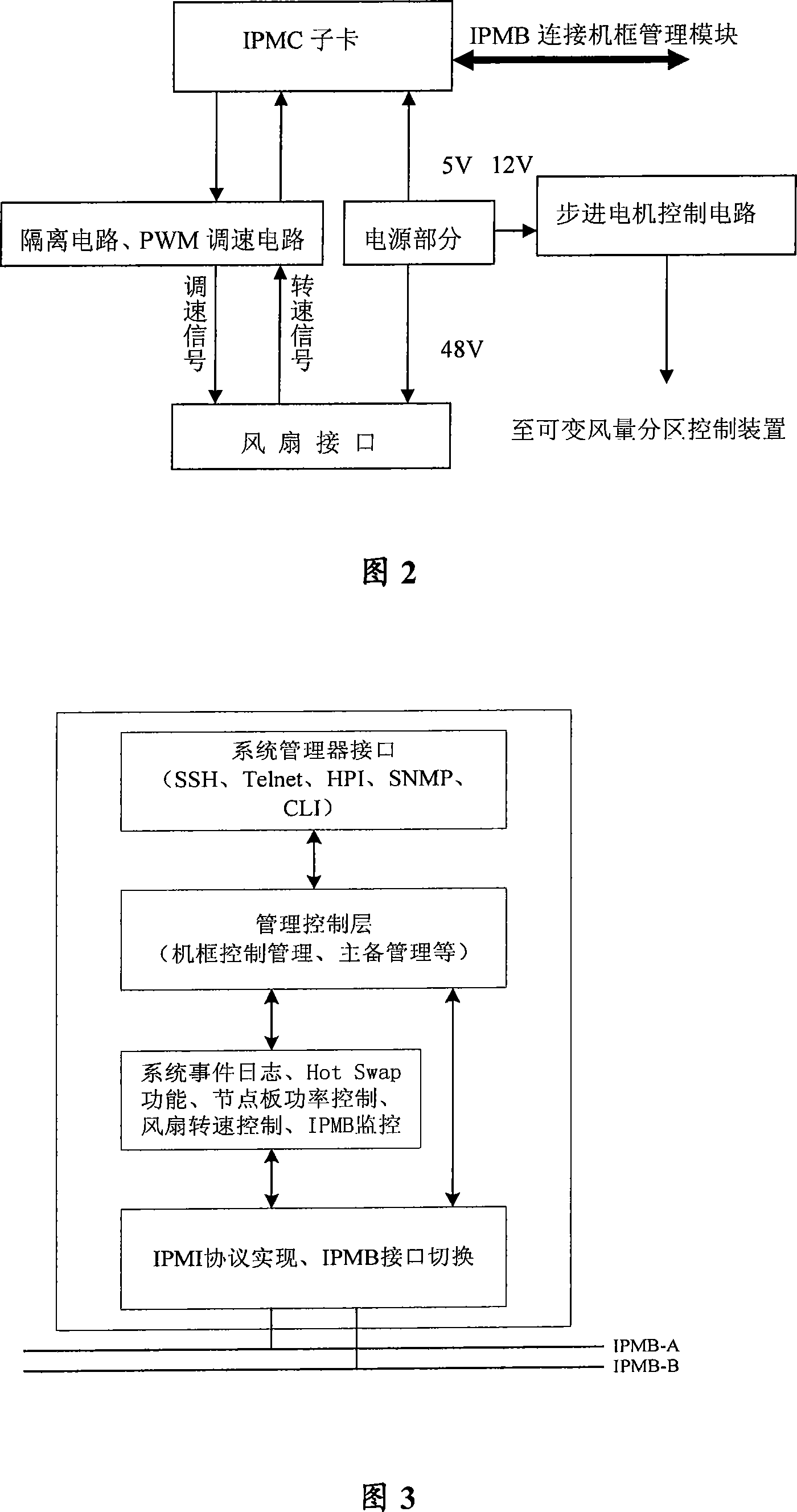

[0037] A. IPMC (Intelligent Platform Management Controller) sub-card module;

[0038] B. Fan control module;

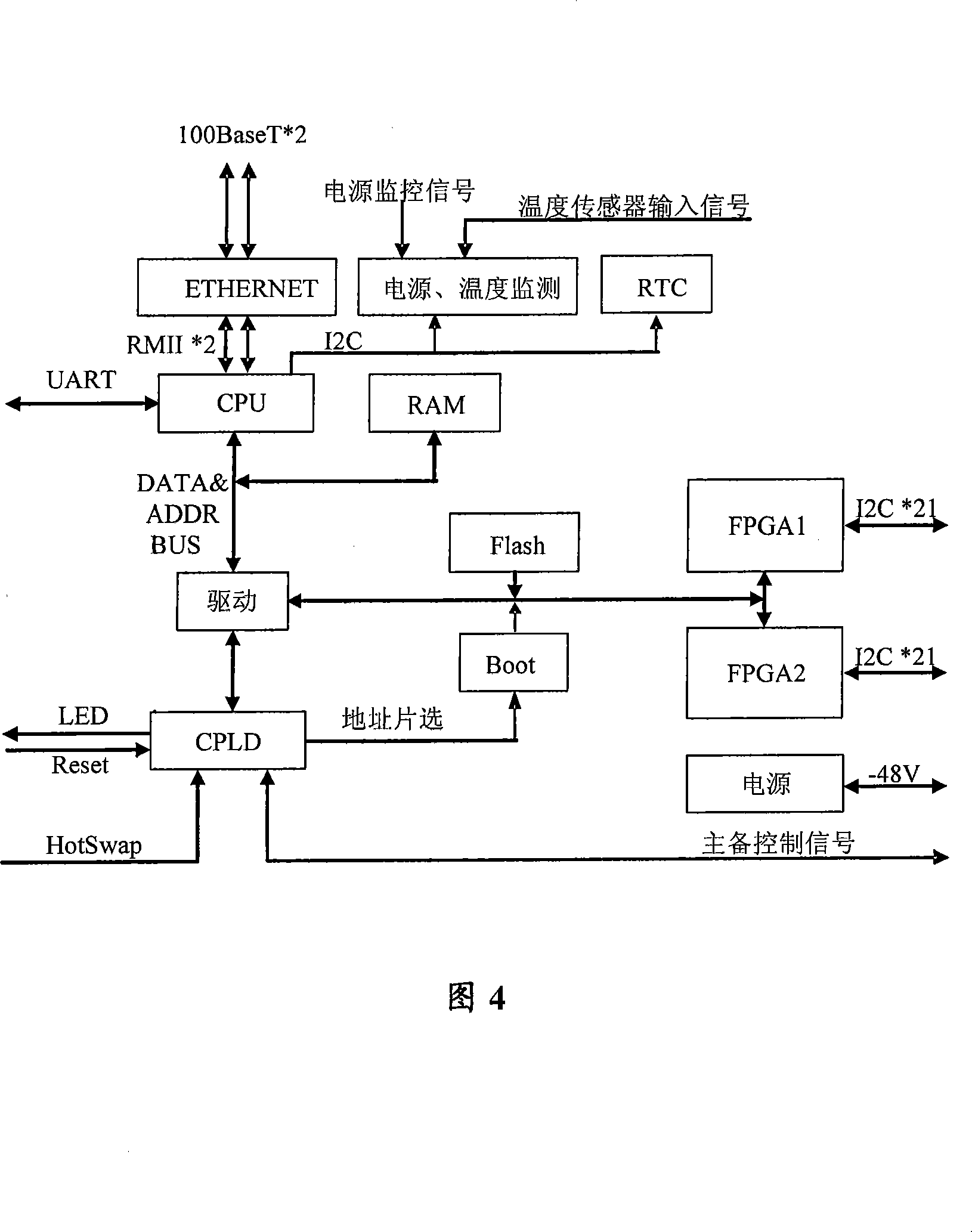

[0039] C. Chassis management module;

[0040] Also includes:

[0041] D. Variable air volume zone control device;

[0042]Among them, modules A, B, and C are all standard modules defined by the existing ATCA specification, and they are also required modules. It is independently located on each ATCA node board, realizes the single board management function specified by PICMG3.0, measures and monitors the status of the node board, records event logs, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com