Carbon brush structure

A technology of carbon brushes and carbon brush holders, applied in the direction of current collectors, electrical components, rotating current collectors, etc., can solve the problems of complex manufacturing process and high cost of carbon brushes 6, reduce component costs, improve heat dissipation, and simplify production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

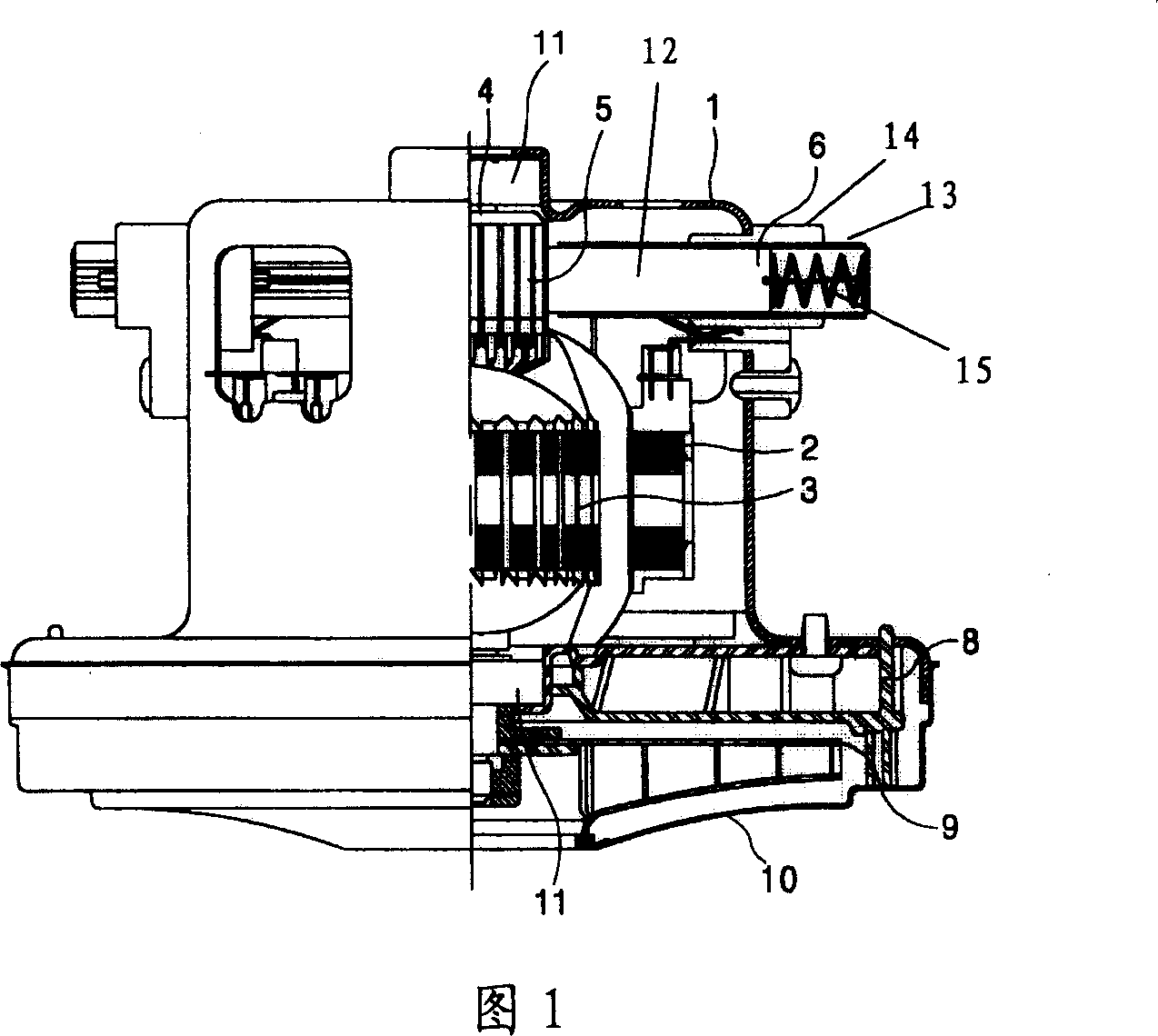

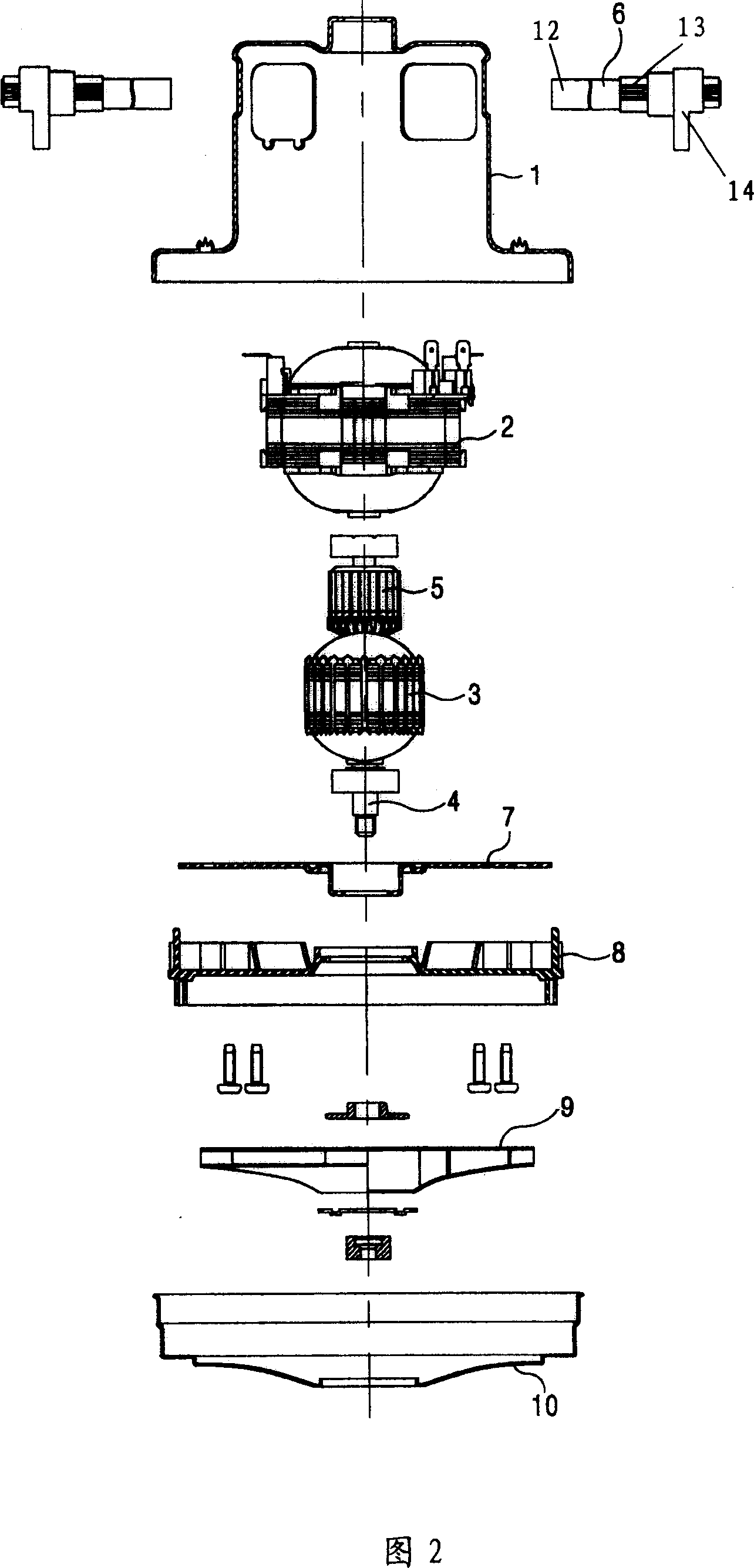

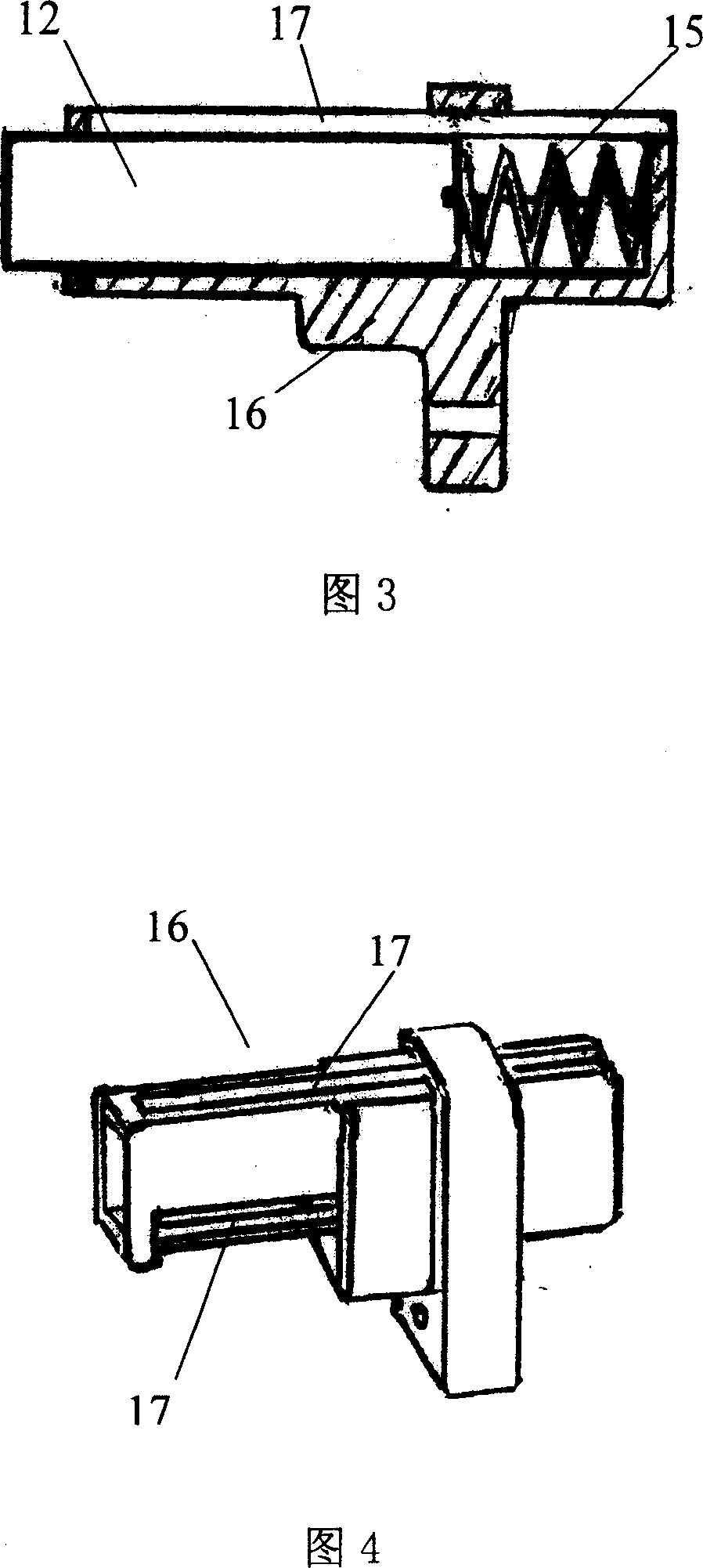

[0023] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0024] Hereinafter, parts that are the same as those in the past are described using the same symbols.

[0025] The single-phase motor includes a stator 2 fixed on the inner side of the casing 1 with an open inner space; the inner side of the stator 2 is provided with a rotor 3 that can rotate at a certain distance from the inner peripheral surface of the stator 2; A rotating shaft 4 is inserted in the center; bearings 11 are arranged on both ends of the rotating shaft 4, and the bearings are fixed by the casing 1 and the guide blades 8, so that the rotating shaft 4 rotates.

[0026] On the upper side of the rotor 3, there is a commutation rectifier 5 that converts the supplied AC current into DC current; on both sides of the commutation rectifier 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com