Oil returning device for stem part of electronic patterning machine

A pattern machine and needle bar technology, which is used in lubrication/cooling devices, sewing machine components, textiles and paper making, etc., can solve the problems of oil leakage at the needle bar, easy storage of oil, loss of clothing manufacturers, etc., to reduce oil leakage and prevent Oil pollution and the effect of improving sewing grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

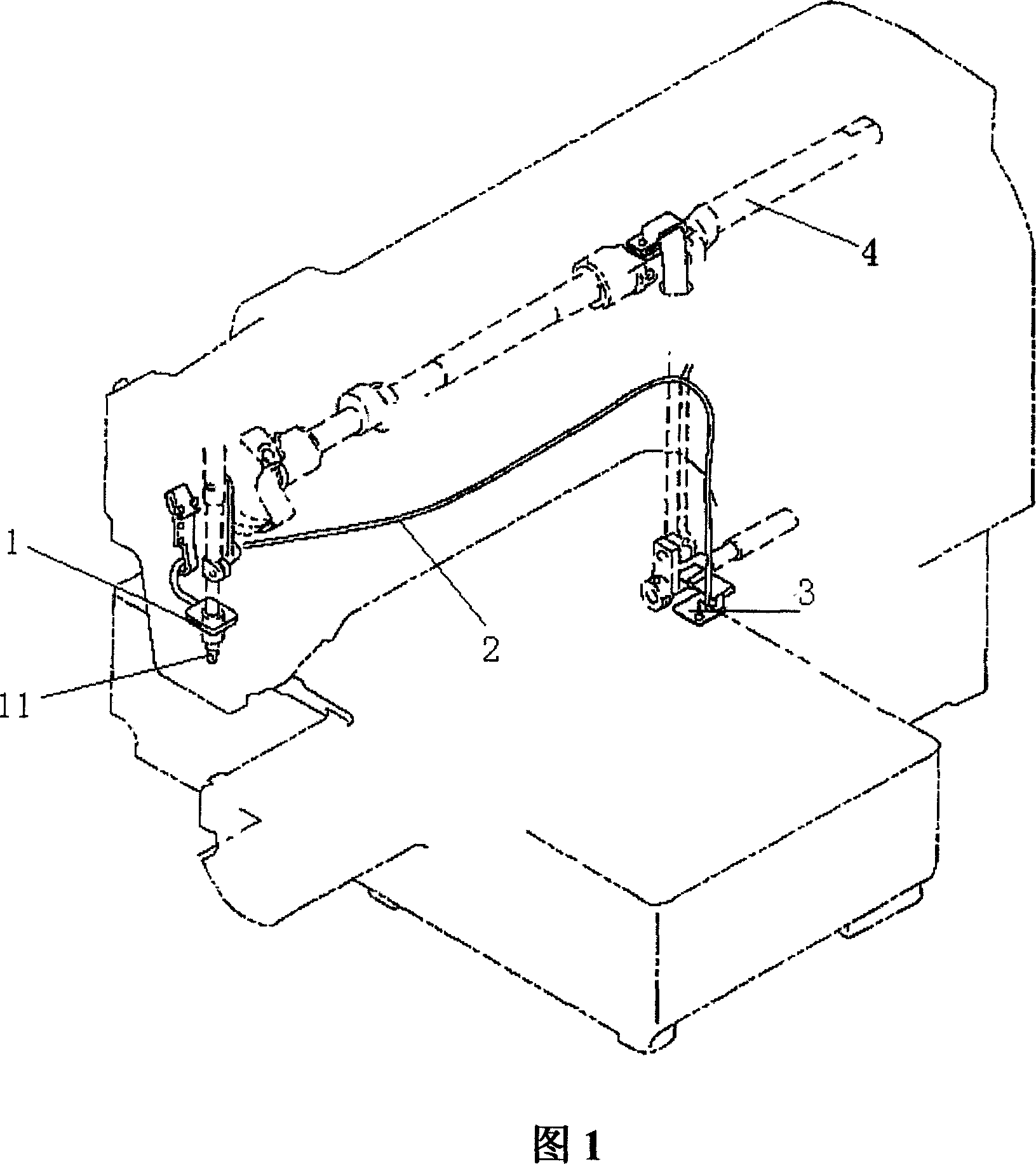

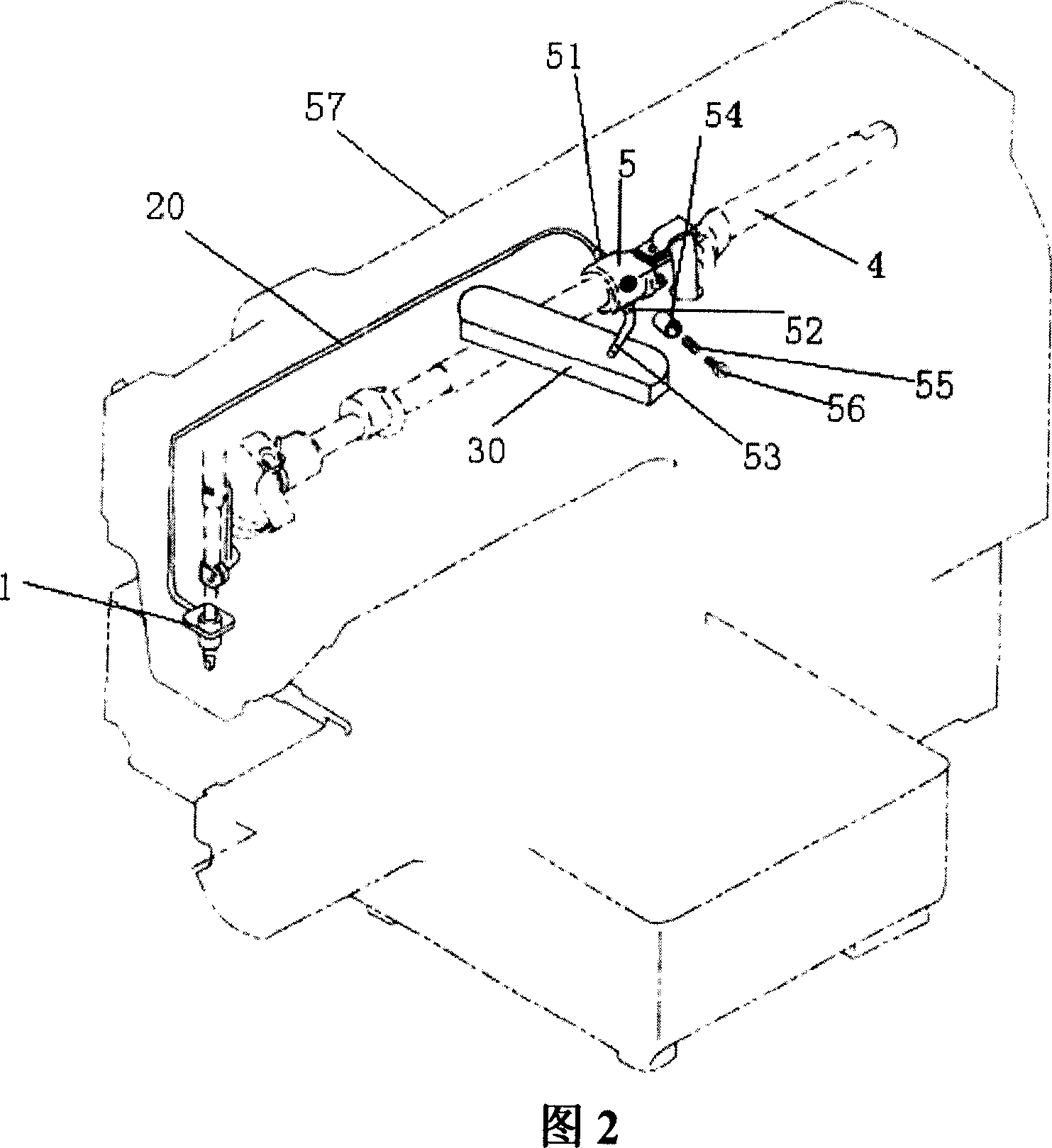

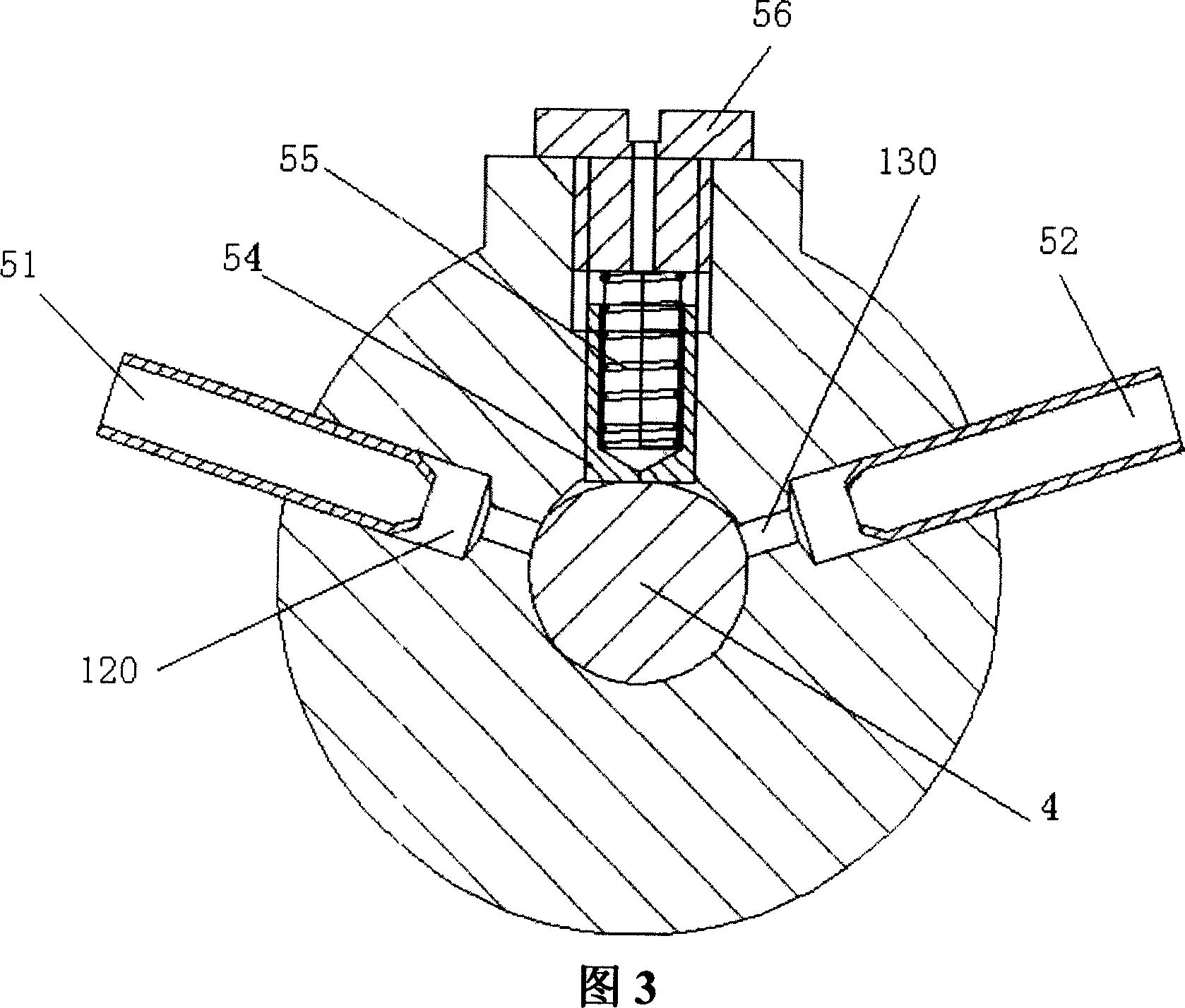

[0014] It can be seen from Fig. 2 and Fig. 3 that the present invention includes: the casing head 1, the first oil pipe 20, the oil box 30, and the upper shaft 4; one end of the first oil pipe 20 is connected with the casing head 1; A shaft sleeve assembly 5; the upper shaft sleeve assembly 5 is sleeved on the upper shaft 4, and the contact with the upper shaft 4 is eccentrically connected; the upper shaft sleeve assembly 5 includes a first oil pipe The other end of 20 is connected to the first oil pipe joint 51, a second oil pipe joint 52 connected to the oil box 30 through the second oil pipe 53; the first oil pipe joint 51 communicates with the second oil pipe joint 52; A plunger 54 is also included between the first oil pipe joint 51 and the second oil pipe joint 52, one end of the plunger 54 forms a closed space with the first oil pipe join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com