Hydraulic speed governing positive wagon

A speed regulation and hydraulic technology, applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems such as the inability to regulate the speed of the hydraulic front box, the increase of drilling costs and costs, and the repair and replacement of drilling stops. Achieve the effect of reducing drilling costs and costs, wide application range and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

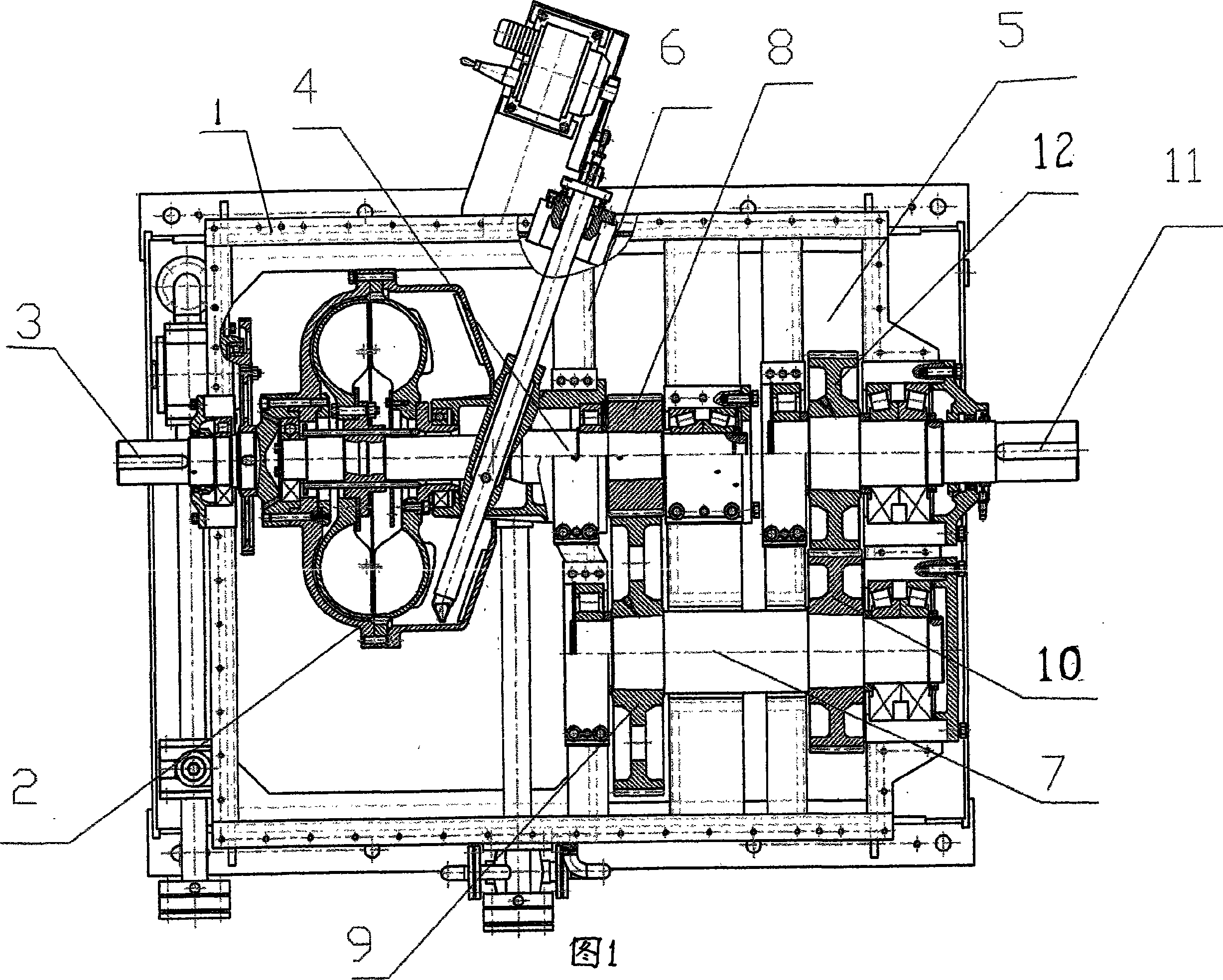

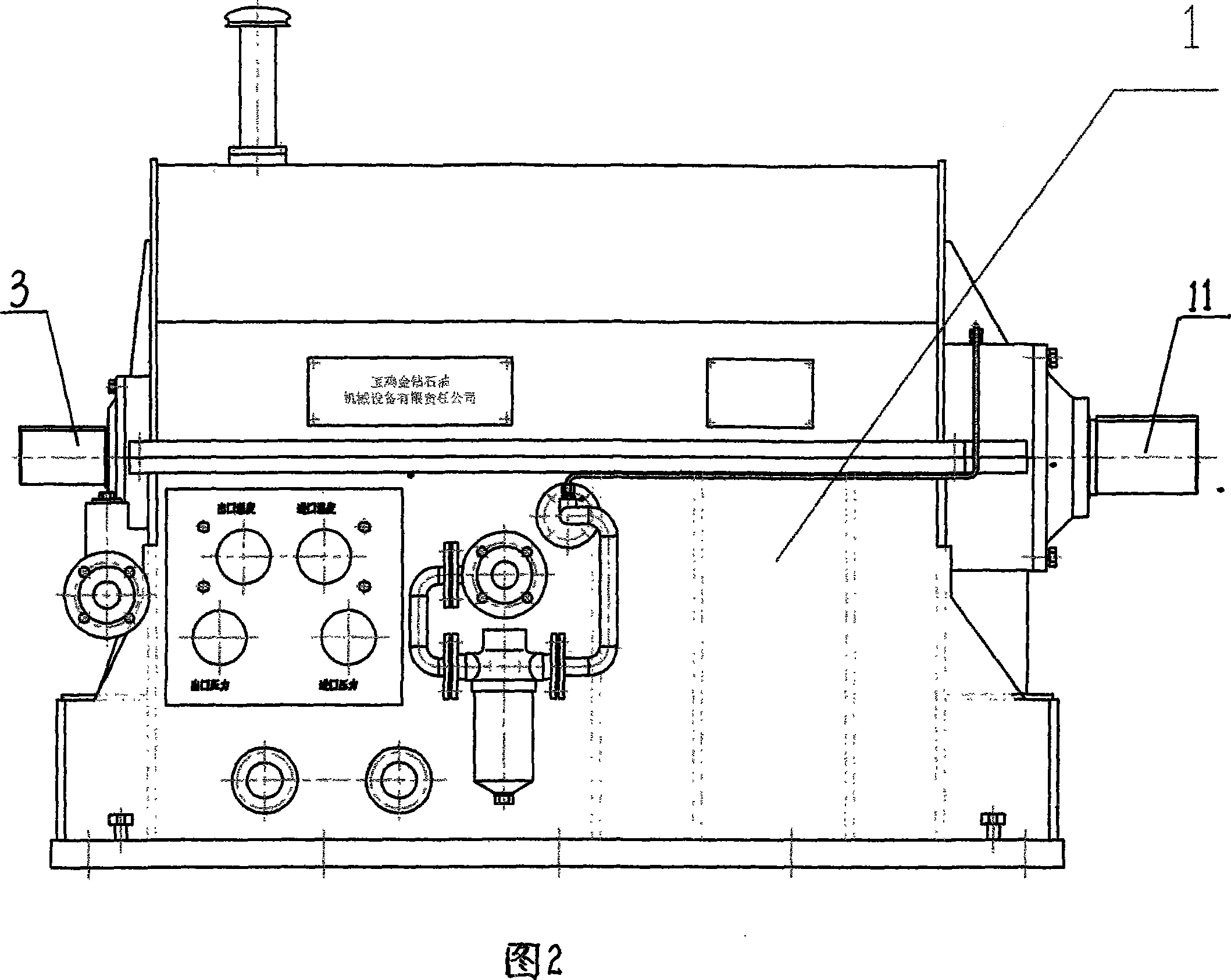

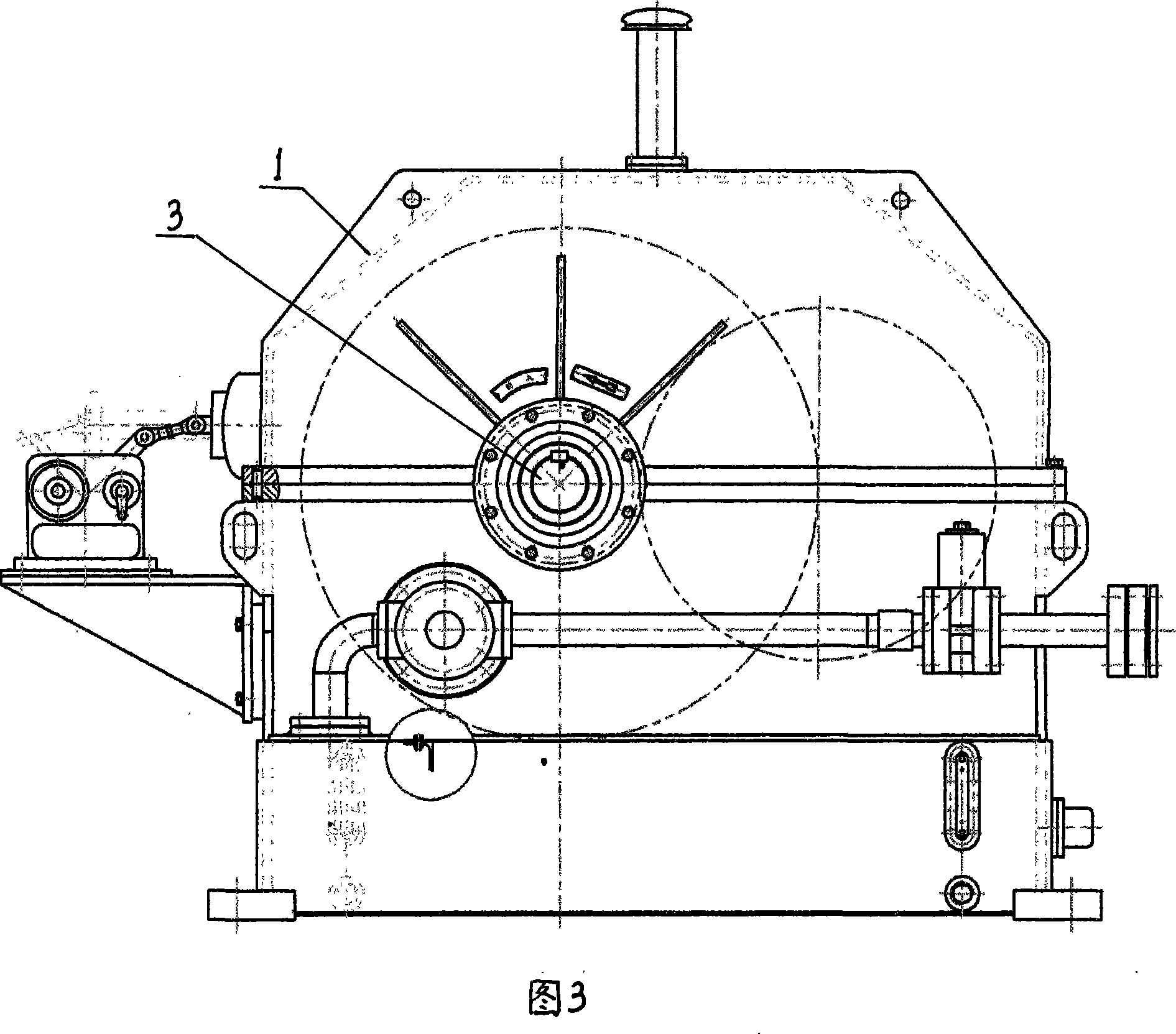

[0017] The first embodiment of the present invention is described in conjunction with accompanying drawings 1, 2, 3.

[0018] A horizontal hydraulic speed regulating front box, including a box body (1), the box body (1) is divided into two parts by a partition (6), and the left part of the box body (1) is a hydraulic coupling ( 2), the right part of the box body (1) is the gear reduction box (5), the power input shaft (3) of the fluid coupling (2) is connected with the main shaft of the power machine, and the power output shaft of the gear reduction box (5) (11) is connected with the working machine, the power output shaft (4) of the fluid coupling (2) is fixed with a small gear (8), and the power input shaft (7) of the gear reduction box (5) is fixed with a large gear ( 9) and the steering gear (10), the power output shaft (11) of the gear reduction box (5) is fixed with the steering gear (12), the pinion (8) meshes with the bull gear (9), and the steering gear (10) Mesh wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com