Structure unit of heating installation

A technology for structural units and heating equipment, applied in lighting and heating equipment, climate sustainability, hot water central heating systems, etc., can solve the problems of limited matching between plastic and hydraulic requirements, and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

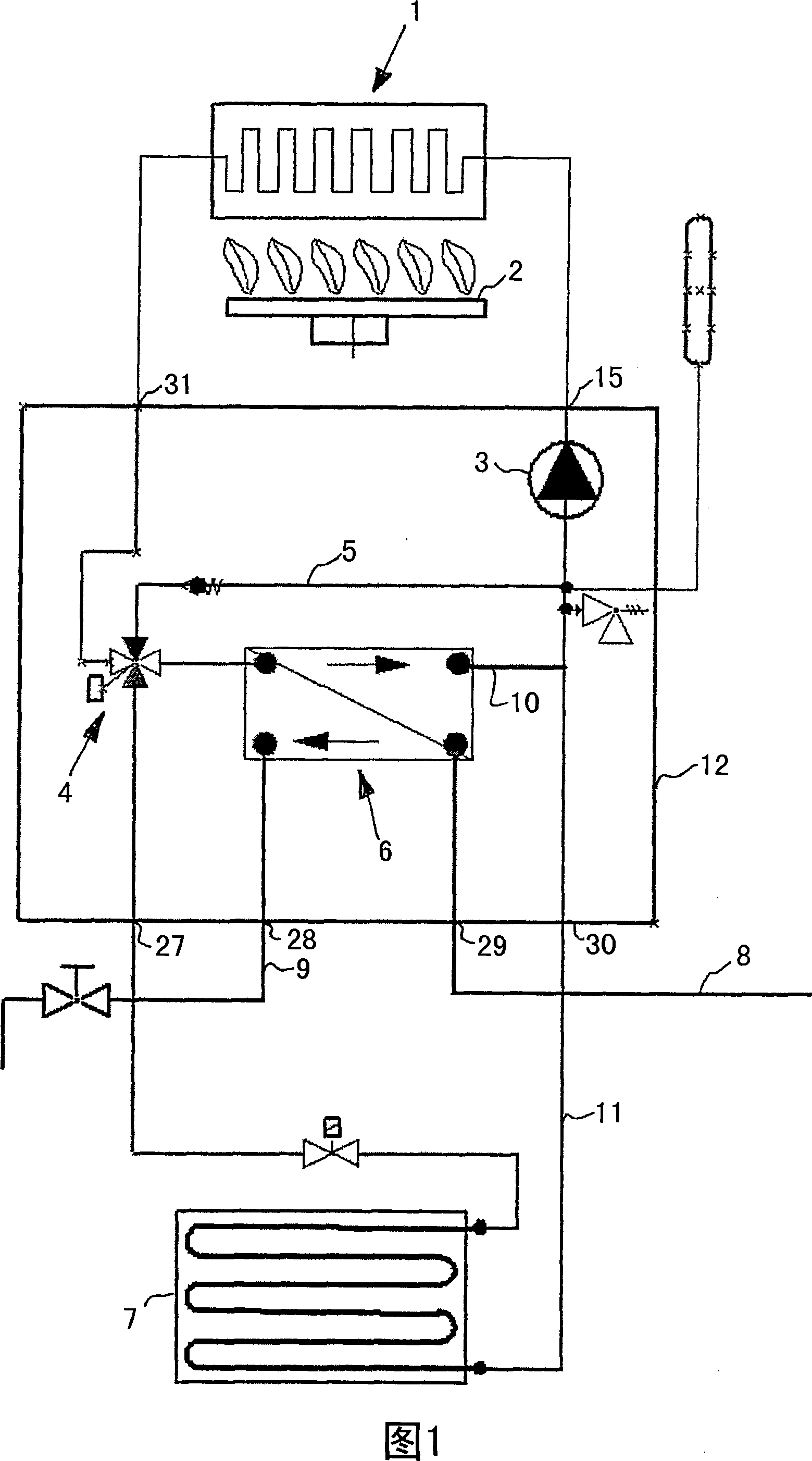

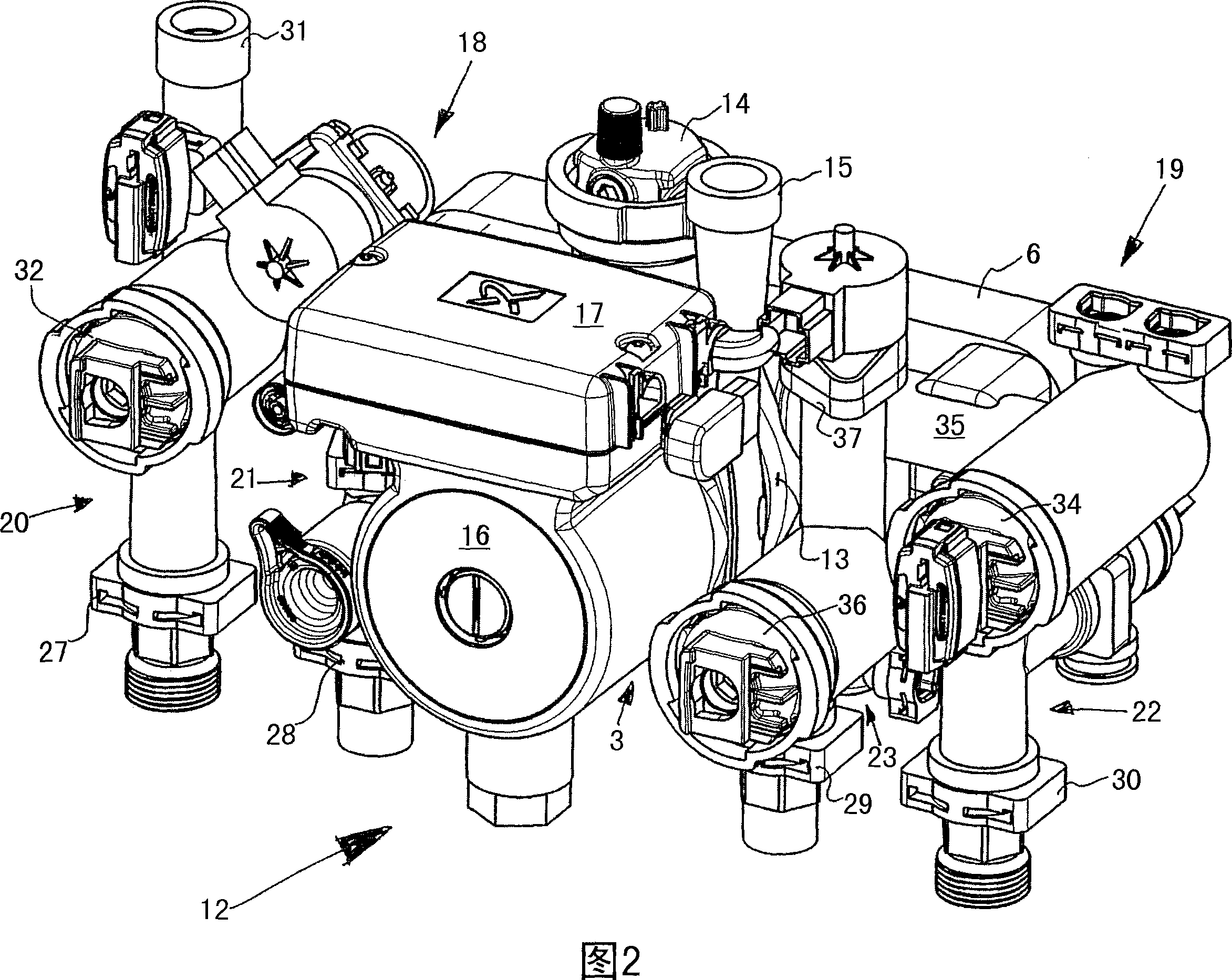

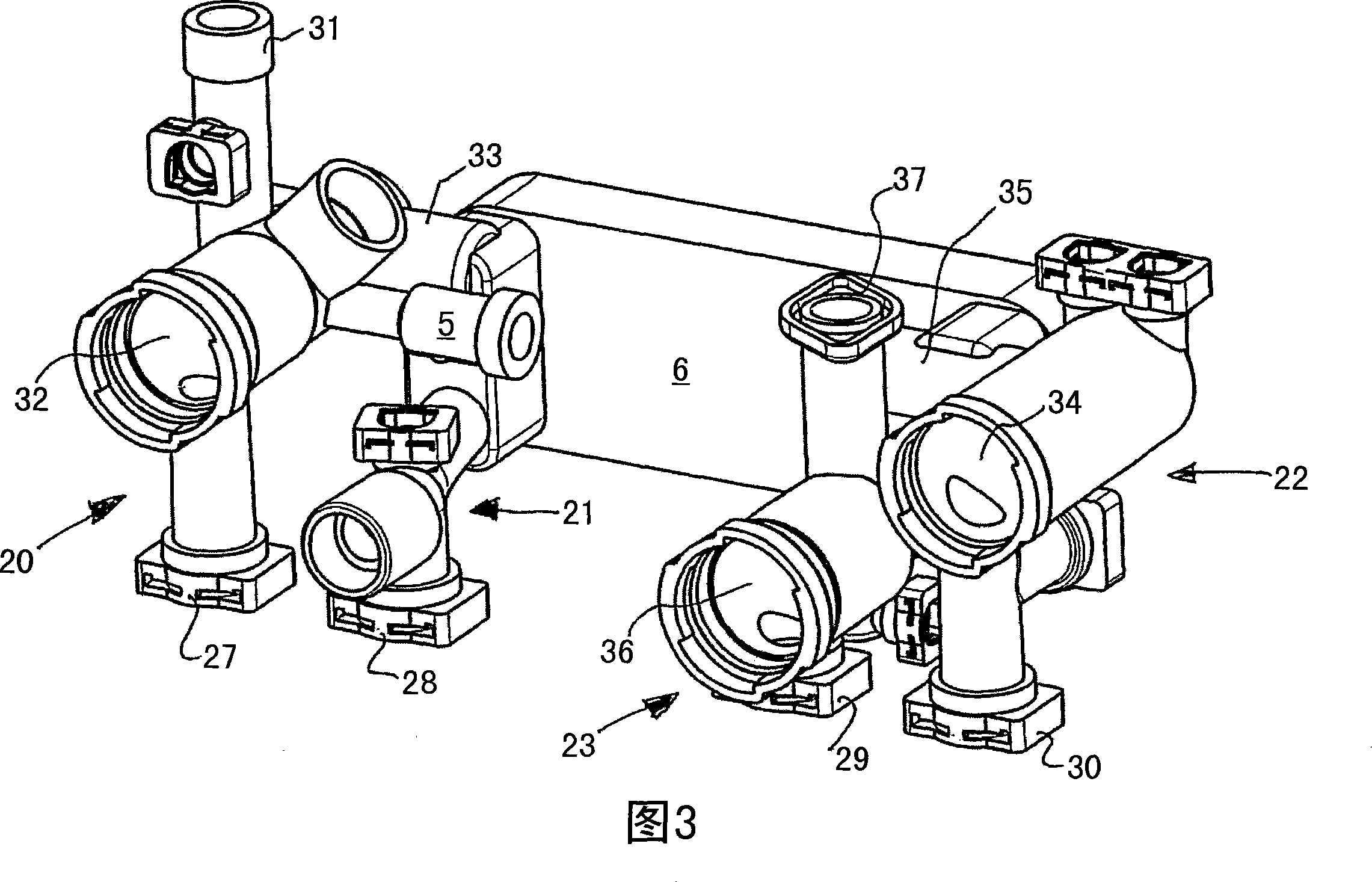

[0040]The heating installation shown in FIG. 1 has a first heating circuit in which circulating water is heated by means of a main heat exchanger 1 with burners 2 . The water flows through the main heat exchanger 1 by means of the circulation pump 3 and is then sent to the 3 / 3 (three-position three-way) reversing valve 4 from which the water is selectively sent to the A connected overflow pipe 5, or a heat exchanger 6 in the form of a fin heat exchanger, or a cooling body 7 for indoor heating. The water can flow back to the circulation pump 3 and thus to the main heat exchanger 1 in a short distance via the overflow pipe 5 . This switching position is used to quickly heat the water circulated there. In the second switching position, the water heated in the main heat exchanger 1 is fed to the plate heat exchanger 6, in which the process water is heated countercurrently, the process water comes from the process water pipe 8 and is heated It leaves the heat exchanger 6 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com