Underground pipe line type seepagefiltrationn alkali-discharging technology

An underground pipeline and infiltration technology, applied in soil drainage, soil protection, soil lifting machinery, etc., can solve the problems of difficulty and high cost of implementation, high investment cost and inconvenience of alkali drainage wells, and increase the economic benefits of land , Improve land utilization and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

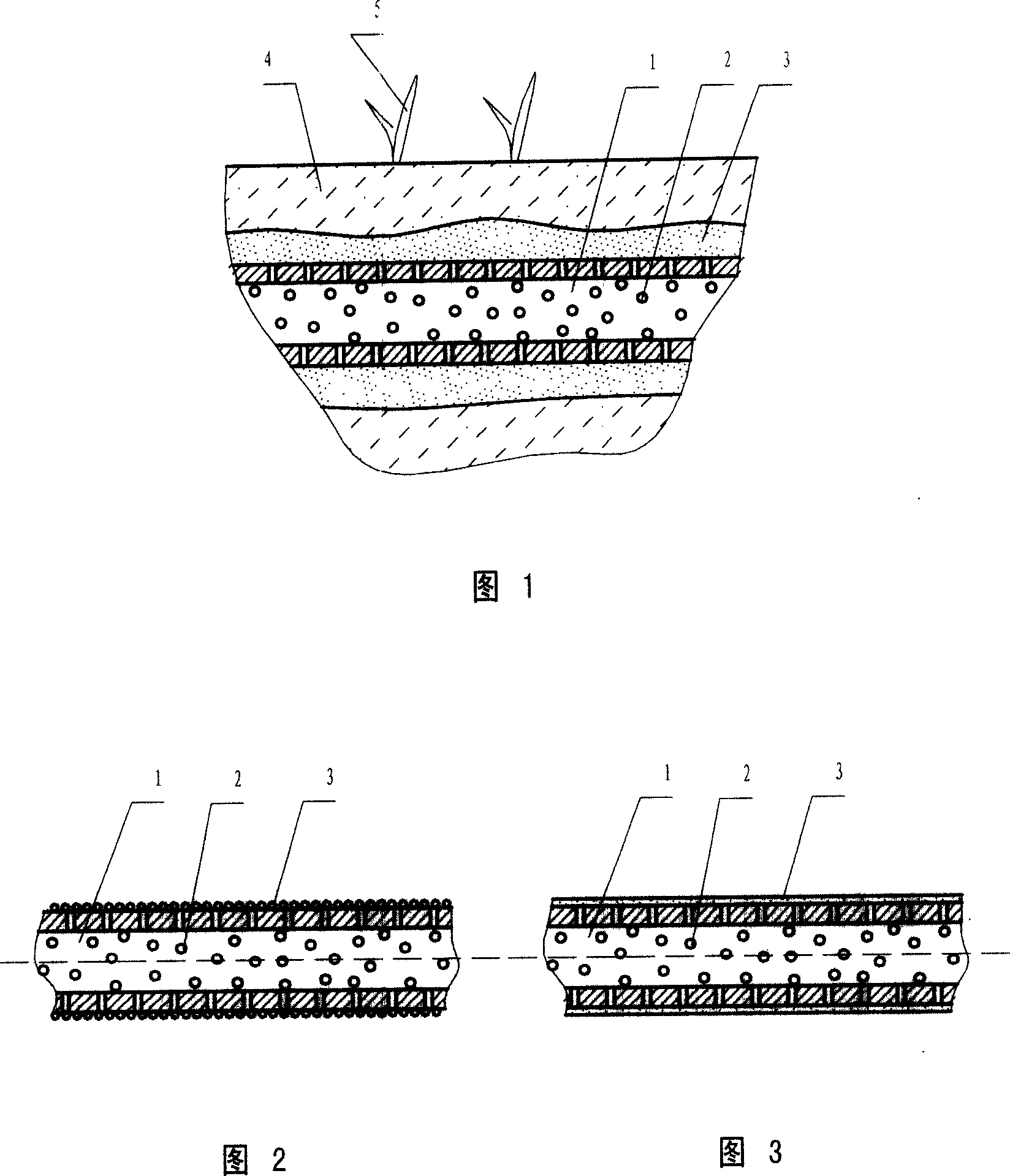

[0015] With reference to Fig. 1, excavate a ditch with a depth of 1 meter at intervals of 10 meters on the well-leveled land with a gradient of ≤1:100, cover the bottom of the ditch with a layer of sand and gravel (3) after the bottom of the ditch is leveled, and cover the top of the ditch densely. A hole (2) with a diameter of 5mm, a distance between the holes of 15mm, and a PVC pipe (1) with a diameter of 100mm are placed at the bottom of the ditch, and the PVC pipe is covered with sand and gravel, and the overlying soil (4) is used to fill up the trench. At the same time, the downstream outlet of the alkali discharge pipe can be connected with the drain.

Embodiment 2

[0017] Dig ditches with a depth of 2 meters at intervals of 150 meters on well-leveled land with a slope ≤ 1:500. After the bottom of the ditch is leveled, cover a layer of mung bean gravel with a diameter of 2 to 5 mm on the gravel. Lay a concrete pipe (1) with a pipe diameter of 200mm and wrapped with a filter screen (3) made of glass fiber filaments. The walls of the concrete pipe are densely covered with holes (2) with a diameter of 20mm, and the distance between the holes is 20mm. Cover the concrete pipe with rocks, fill up the trench with soil, and connect with the drainage ditch at the downstream outlet of the alkali discharge pipe.

Embodiment 3

[0019] Dig a trench with a depth of 3 meters at intervals of 300 meters on a well-leveled land with a slope ≤ 1:2500. After leveling the bottom of the trench, spread a layer of sand and gravel on the bottom of the trench, and densely cover the circumference with holes with a diameter of 10 mm (2) , The distance between the holes is 20mm, the diameter of the pipe is 200mm, and the filter mesh (3) made of filter cloth with a diameter of 2mm is wrapped around the pipe. The PVC pipe (1) is placed at the bottom of the ditch, and the PVC pipe is covered with sand , cover and fill up the ditch, and at the same time communicate with the drain at the downstream outlet of the alkali discharge pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com