Railway motor trolley power-driven bi-parting sliding plug door system

A technology for rail trains and sliding doors, applied in door devices, vehicle locks, windows/doors, etc., can solve the problems of increasing the technical difficulty of the door system, unable to meet the needs of the society, increasing the opening degree, etc., and achieve installation, commissioning and maintenance. The effect of convenience, large carrying capacity, increased safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

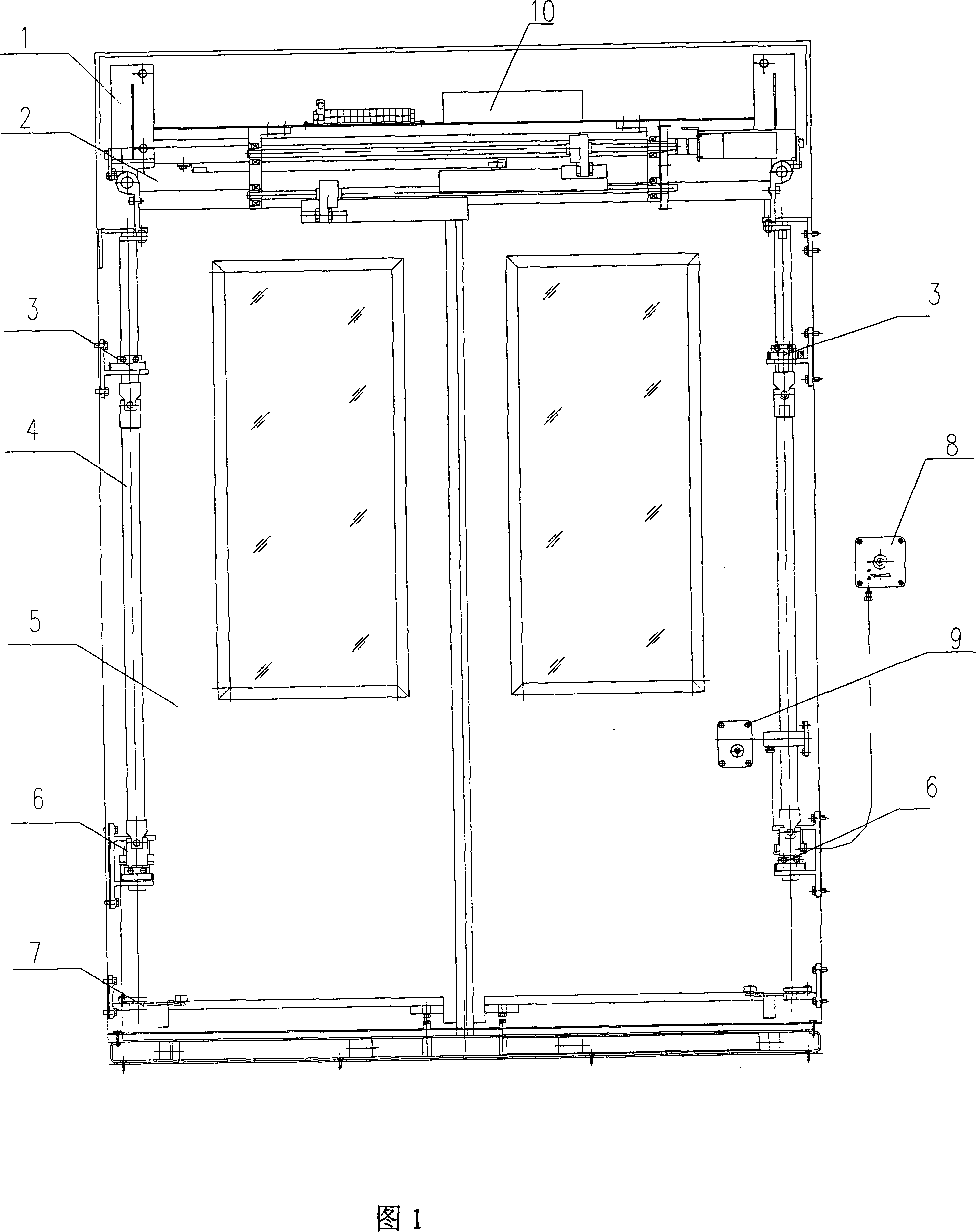

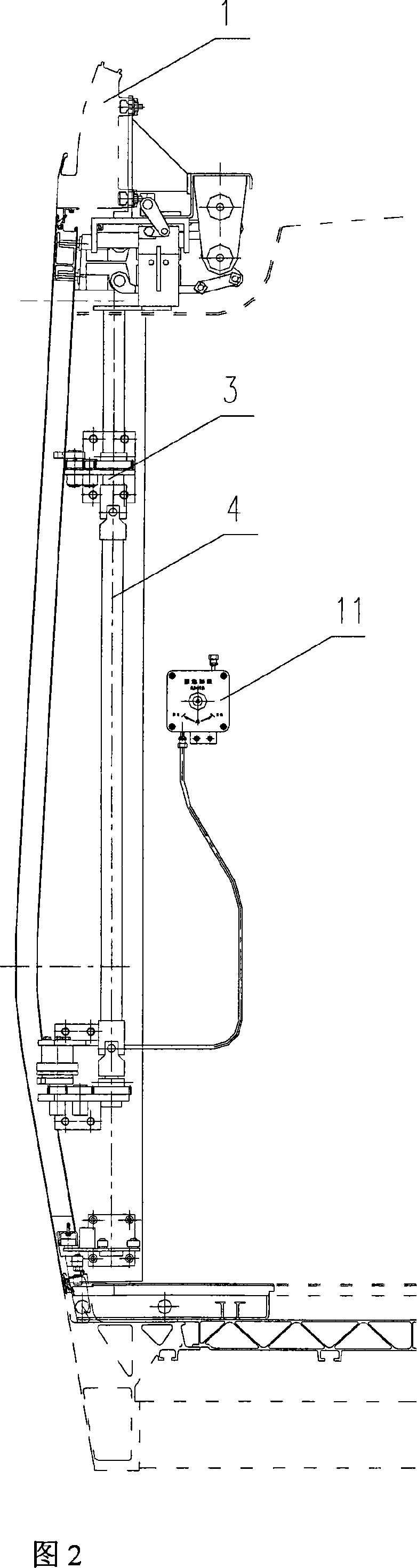

[0011] Referring to the accompanying drawings, its structure is that the load-bearing drive mechanism 2 is installed on the top of the car body 1, and the door leaf 5 is connected with the load-bearing drive mechanism 2 through the door frame; connected, and installed on both sides of the car body 1 after being connected with the locking device 6 at the middle and lower part of the car door, the rollers in the lower swing arm mechanism 7 are in the lower guide rail at the bottom of the car door; the outer operating device 8 installed on the outside of the car body 1 and The emergency operating device 11 installed inside the vehicle body 1 is connected to the locking device 6 through a wire rope;

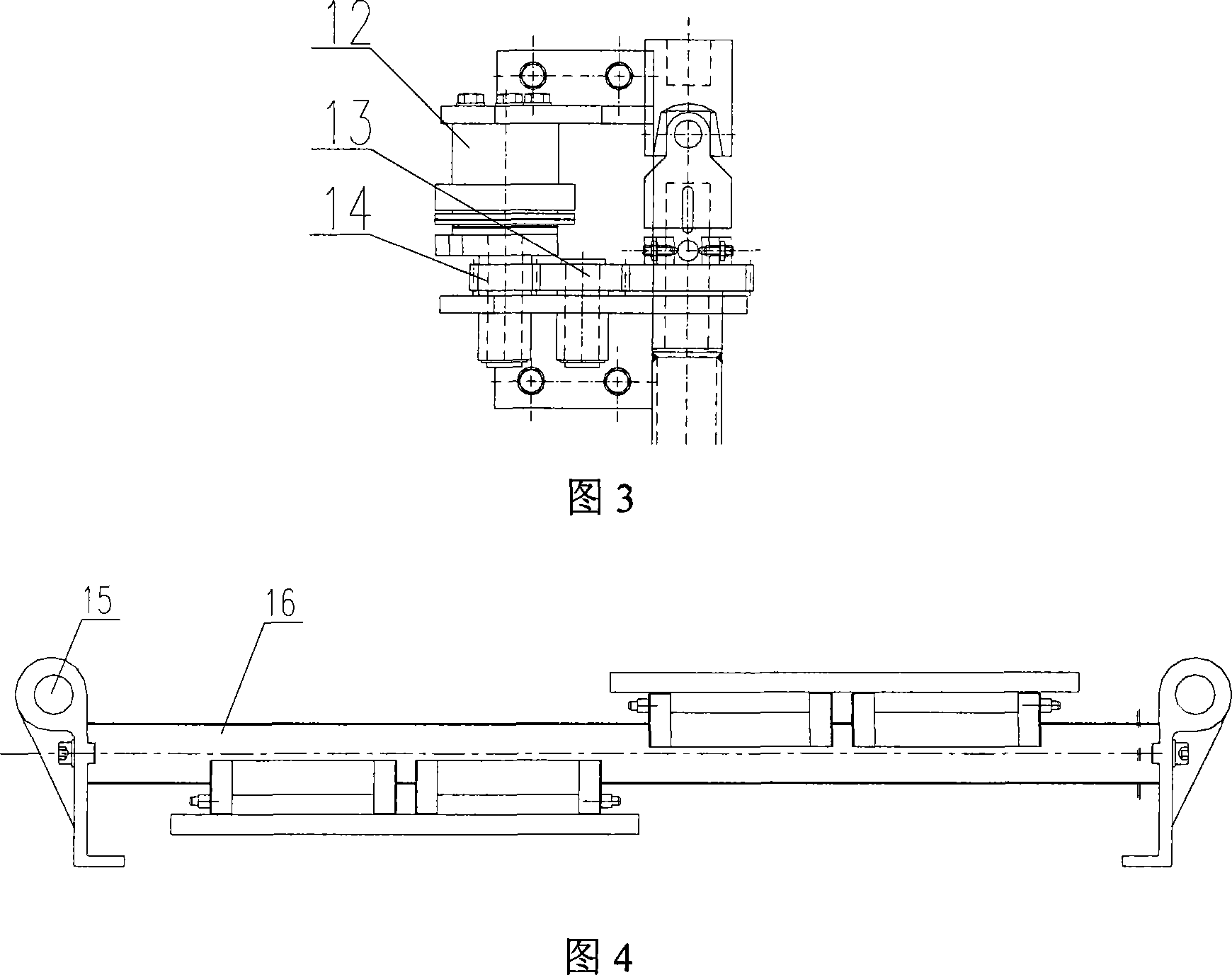

[0012] The upper slideway in the load-carrying drive mechanism 2 is installed on the base plate, and the left and right short guide posts on both sides of the upper slideway are respectively installed on the base plate through brackets, and a hanger is respectively installed on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com