Multiple layer synthesis furnace device

A synthesis furnace and compound technology, applied in the field of multi-layer compound synthesis furnace devices, can solve the problems of high production cost, poor safety, hindering the development of information materials business, etc., and achieve high product quality, high purity, and ensure productivity and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

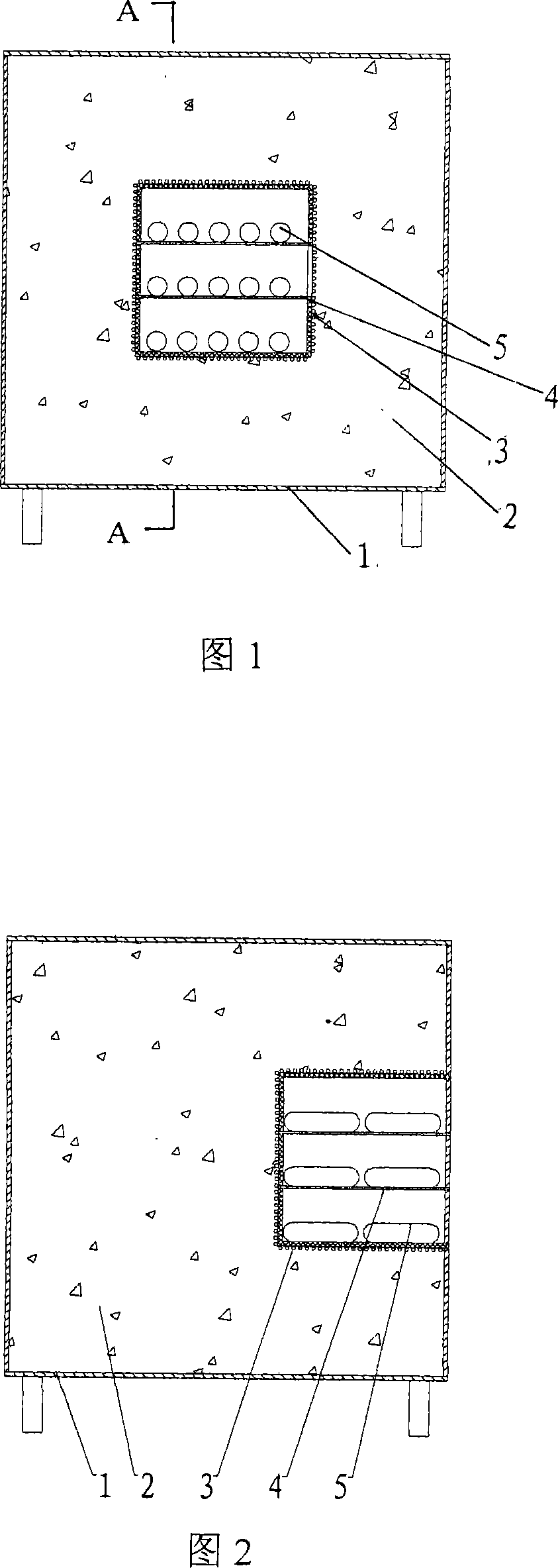

[0017] The multilayer compound synthesis furnace device of the present invention has a simple structure and is easy to manufacture, as shown in FIG. 1 . The synthesis furnace 1 is provided with a high-temperature refractory brick insulation layer 2, a silicon carbon tube is used as a heating source, and a heating wire 3, a heat insulation board 4 and a synthesis reaction tube 5 are arranged in the heating source, and the furnace chamber of the synthesis furnace is separated by a heat insulation board 4. Multiple synthesis chambers, multiple synthesis reaction tubes 5 are placed in each synthesis chamber, and the uniform temperature distribution of the thermal field inside the furnace chamber is strictly controlled. The temperature gradient of the thermal field is ≤±5°C / cm. process security.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com