Method for analyzing welding quality of aluminium alloy with X radiograph

A welding quality and X-ray technology, which is applied in the field of analyzing aluminum alloy welding quality, can solve problems such as the complexity of film evaluation knowledge, achieve automatic defect evaluation, realize automatic comprehensive evaluation, and save time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

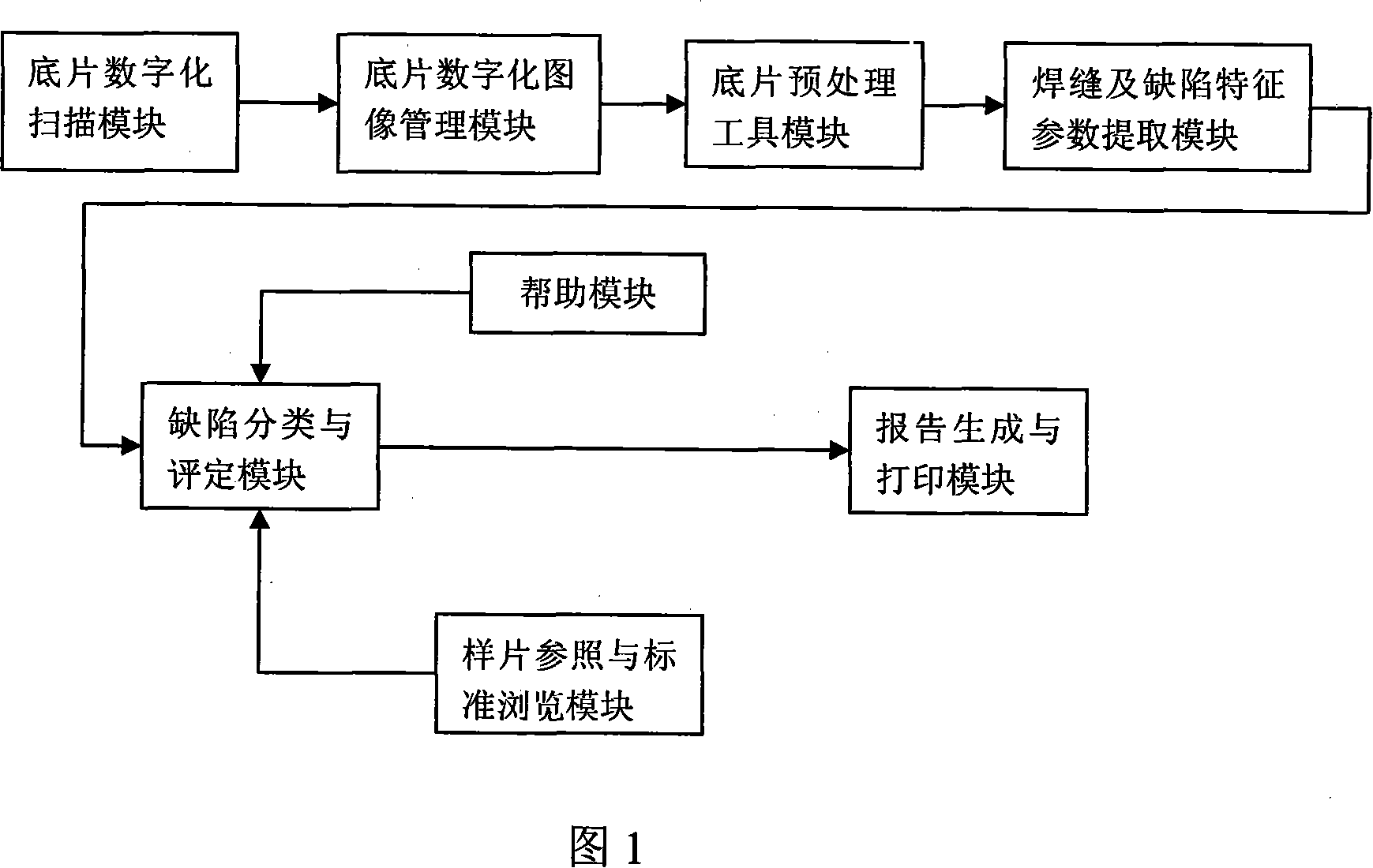

[0039] In the present invention, the software system is a structure supporting multiple documents and multiple views; it is open and expandable. The system supports comprehensive industrial X-ray film analysis and processing functions such as film scanning, storage, analysis, management, evaluation and report printing. The system has a friendly interface and is easy to operate, adopting the familiar WINDOWS system interface style.

[0040] As shown in Figure 1, the present invention is as follows to the processing of X-ray film, analysis step:

[0041] (1) The negative film digital scanning module realizes the communication between the image input device, that is, the scanner, and the system software according to the international TWAIN standard and protocol. In the operation, the film can be scanned directly, and the scanning program of the selected scanner can be called to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com