Camshaft device and method of assembling camshaft device

An assembly method and camshaft technology, which can be applied to valve devices, shafts and bearings, valve driving devices, etc., can solve problems such as extra labor and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

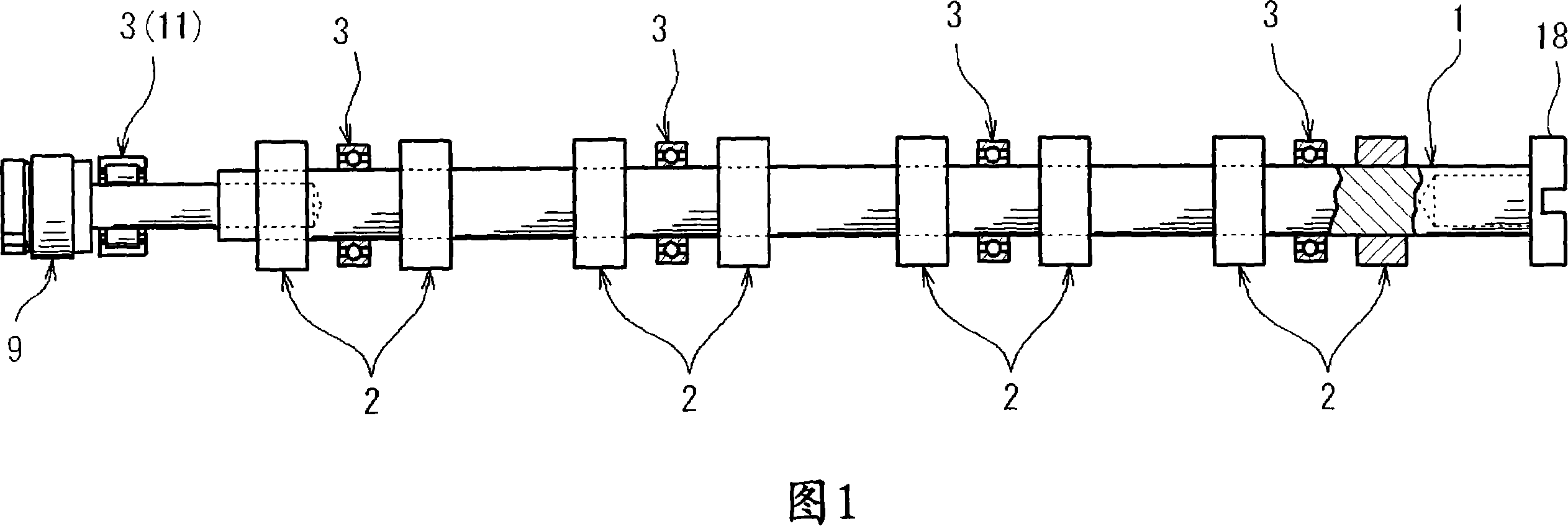

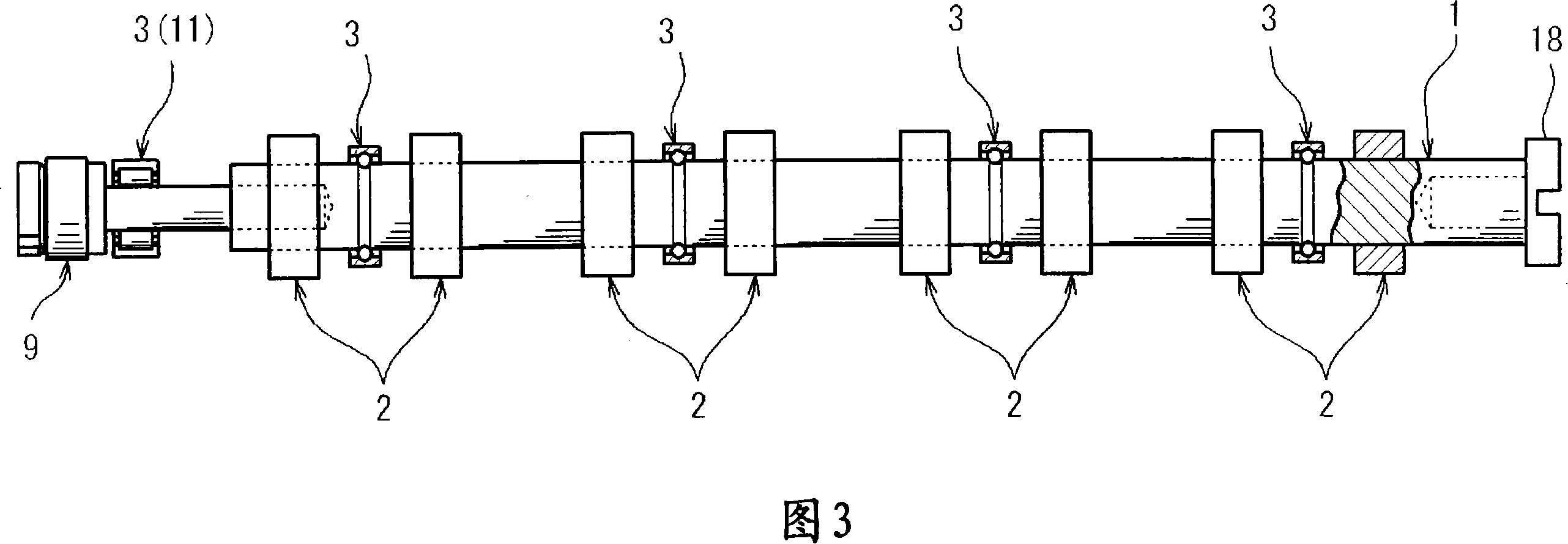

[0042] FIG. 1 is a side view showing a partial section of a camshaft device according to an embodiment of the present invention. This camshaft device can be applied, for example, to a camshaft mechanism for actuating intake and exhaust valves of an automobile engine. This device is formed by arranging a plurality of cams 2 and a plurality of rolling bearings 3 at predetermined positions in the axial direction of the camshaft 1 on the camshaft 1 . In addition, one rolling bearing 3 is provided between the cams 2 as a pair.

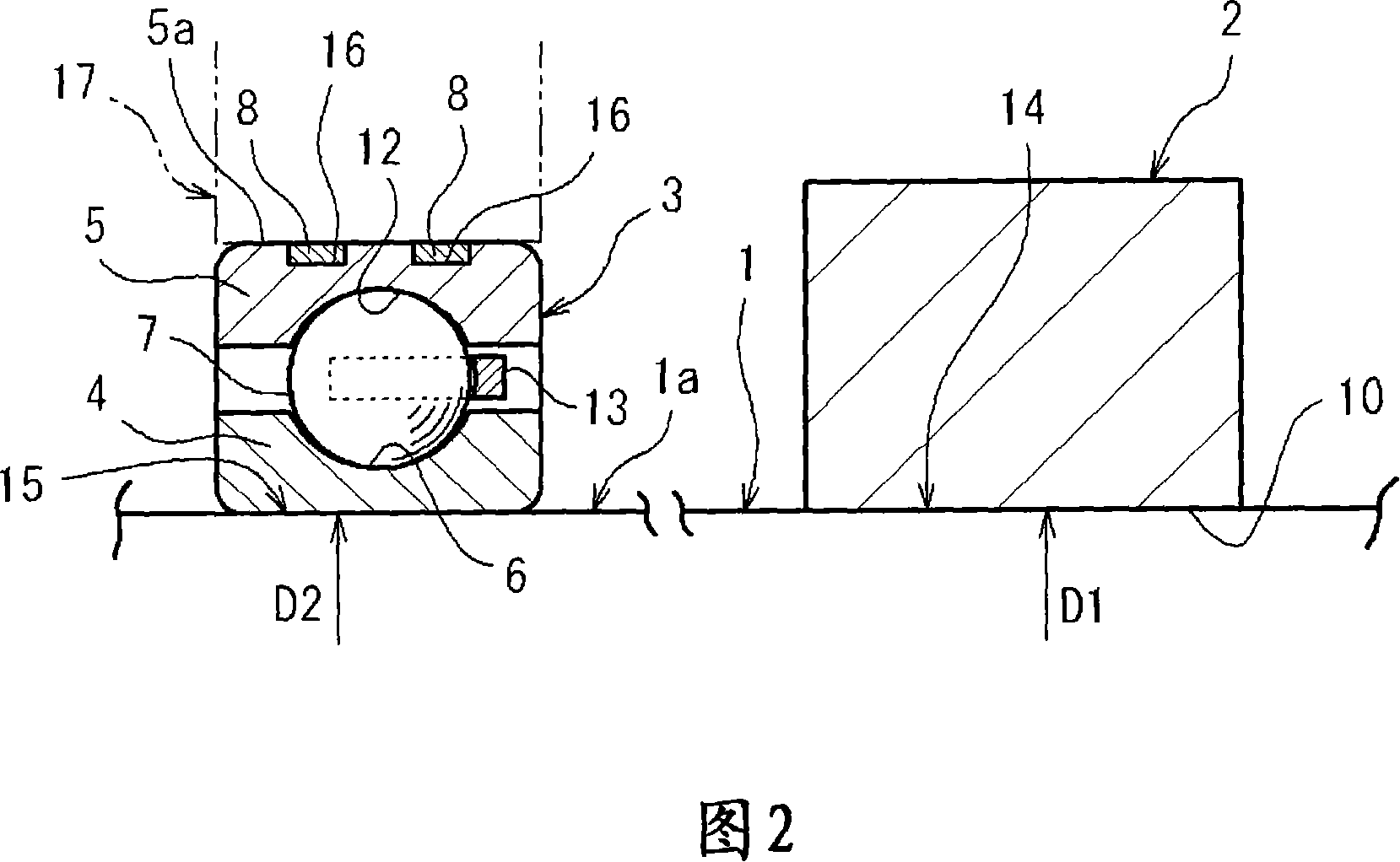

[0043] Fig. 2 is an enlarged cross-sectional view showing a main part of Fig. 1 . This device includes: a linear camshaft 1, an elliptical cam 2 that is separate from the camshaft 1 and mounted on the camshaft 1 in an external fit shape, and a plurality of rolling bearings 3 that rotatably support the camshaft 1. .

[0044] That is to say, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com