Method for determining optimal oil pumping rate of beam-pumping unit

A beam pumping unit and the best technology are applied in the field of determining the optimal pumping rate of the beam pumping unit, which can solve problems such as mismatching, and achieve the effects of improving pump efficiency and reducing oil consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

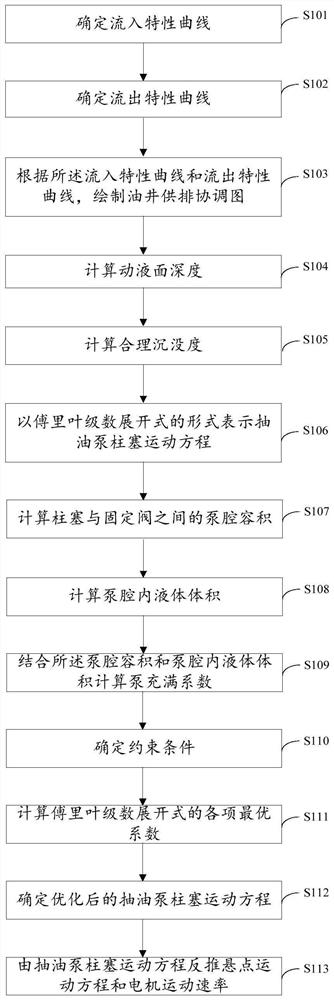

[0053] like figure 1 As shown, the method for determining the optimal pumping rate of the beam pumping unit in the present application includes: S101, determining an inflow characteristic curve; S102, determining an outflow characteristic curve; S103, drawing an oil well according to the inflow characteristic curve and the outflow characteristic curve Supply and discharge coordination diagram; S104, calculate the dynamic liquid surface depth; S105, calculate the reasonable subsidence degree; S106, express the motion equation of the pump plunger in the form of a Fourier series expansion; S107, calculate the distance between the plunger and the fixed valve S108, calculate the liquid volume in the pump cavity; S109, calculate the pump filling coefficient by combining the pump cavity volume and the liquid volume in the pump cavity; S110, determine the constraints; S111, calculate the Fourier series expansion Optimal coefficients of each item; S112, determine the optimized oil well...

Embodiment 2

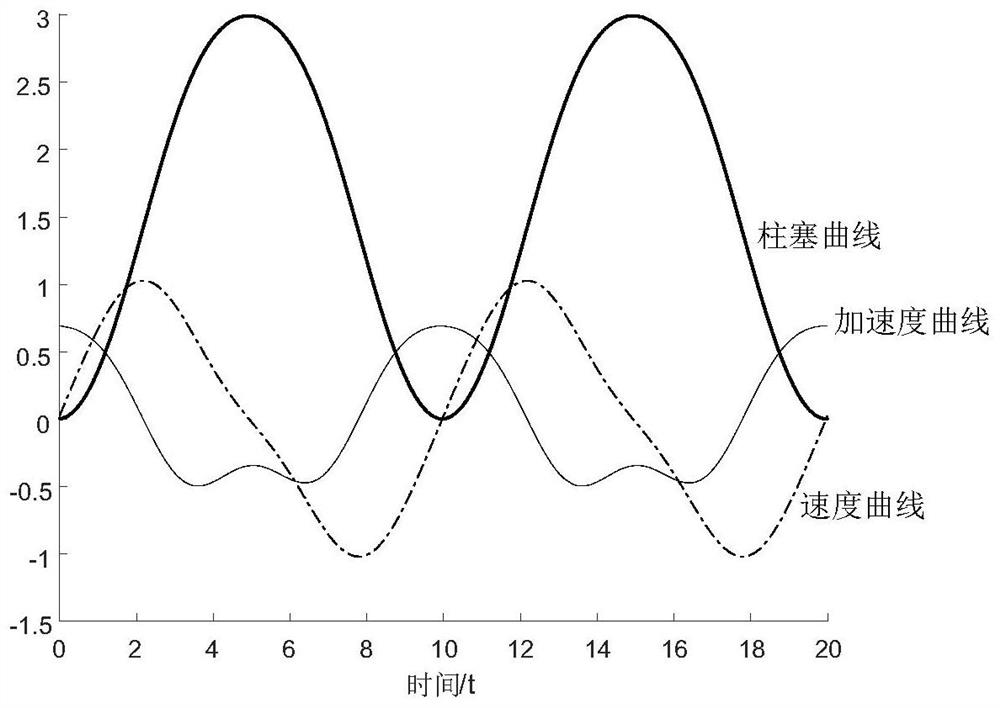

[0056] The invention proposes for the first time that the Fourier series is used to construct the motion equation of the oil well pump plunger, the pump fullness coefficient is used as the optimization objective function, and the pump efficiency and the life of the sucker rod are the constraints to calculate and solve the optimal oil well pump piston motion The law equation is used to reverse the suspension point and the motor movement rate using the plunger motion law equation, so as to obtain the optimal pumping rate that matches the downhole working conditions.

[0057] The method of the present application includes the following steps: (1) combining parameters such as bottom-hole flow pressure, fluid production index, formation pressure, saturation pressure, etc., to obtain an oil well fluid production equation, and determine the inflow characteristic curve; (2) combining subsidence pressure, tubing diameter, friction (3) According to the inflow characteristic curve and the...

Embodiment 3

[0086] The pumping unit is CYJ10-3-37HB type, with a stroke of 3m and a stroke of 6min -1 . The basic parameters of the oil well and the physical properties of the fluid are shown in Table 1:

[0087] Table 1 Basic parameters and fluid physical parameters of oil wells

[0088]

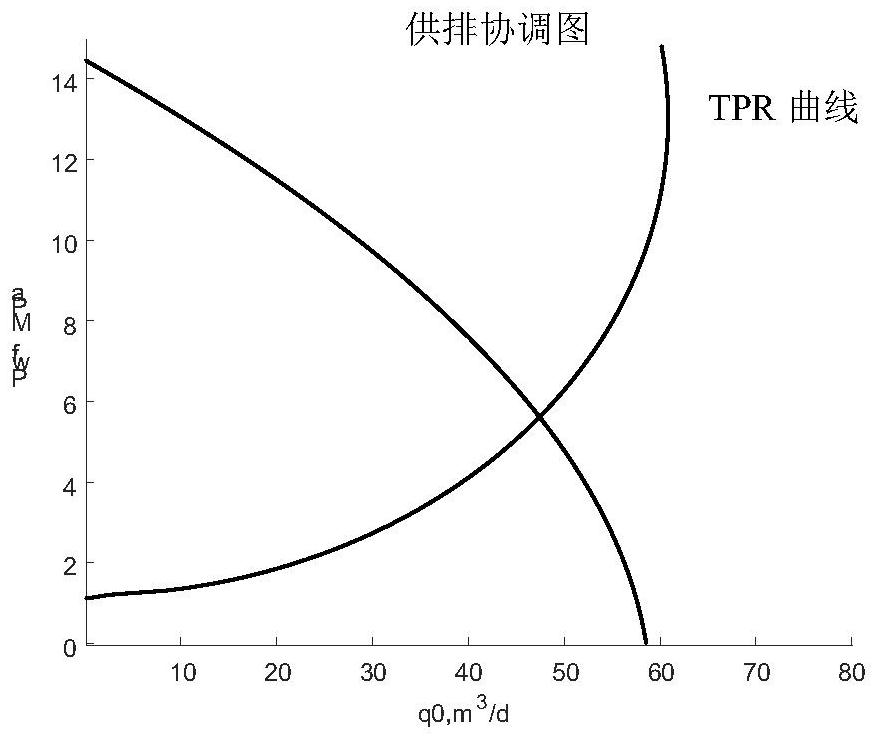

[0089] as attached figure 2 As shown, first determine the inflow characteristic curve q according to the basic parameters of the oil well o =6.045(14.8-p wf ), and outflow characteristic curve And draw the supply and discharge coordination diagram of the oil well. The intersection of the two curves in the figure is the best supply and discharge coordination point, and this numerical point is the best point where the oil well can obtain the maximum lifting output (that is, p wf =5.5MPa,q o =48m 3 / d). According to the determined optimal supply and discharge coordination point values and basic parameters of the oil well, the dynamic liquid surface value is calculated to be 860m and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com