Grinding wheel for hard material processing and preparation method thereof

A hard material and grinding wheel technology, applied in the field of grinding wheel manufacturing, can solve the problems of insufficient sharpness, high brittleness of binder, short life and other problems, and achieve the effect of improving efficiency and stability, improving sharpness and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a grinding wheel for grinding cemented carbide gap grinding, which includes a grinding wheel substrate, a transition layer and an abrasive layer from the inside to the outside; wherein the raw materials used in the abrasive layer include abrasives and metal bonds; the abrasives are polycrystalline Nickel-plated diamond has a coating weight gain of 30% and a particle size of D126; the metal bond includes the following components by weight: 70 parts of copper powder, 25 parts of tin powder, and 5 parts of silver powder; the raw material used for the transition layer is copper powder.

[0028] The preparation method of the above-mentioned emery wheel for grinding cemented carbide gap grinding, comprises the following steps:

[0029] (1) Mix the abrasive material and the metal bond at a volume ratio of 30:70, place the mixture in a three-dimensional mixer for 2 hours, and then take it out to pass through a 200-mesh sieve; pass the copper powder used ...

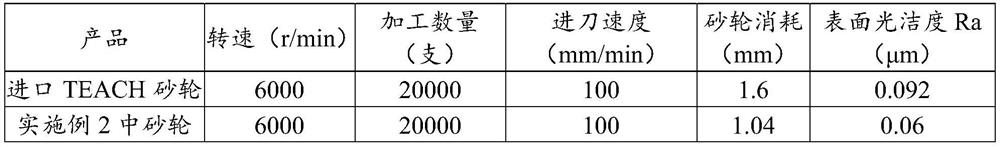

Embodiment 2

[0034] This embodiment provides a grinding wheel for grinding high-speed steel with a gap, which includes a grinding wheel matrix, a transition layer, and an abrasive layer from the inside to the outside; wherein the raw materials used in the abrasive layer include abrasives and metal bonds; the abrasives are cubic nitrided Boron (CBN), not coated, particle size is B126; the metal bonding agent includes the following components by weight: 70 parts of copper powder, 25 parts of tin powder, and 5 parts of silver powder; the raw material used for the transition layer is copper powder.

[0035] The preparation method of the above-mentioned emery wheel for grinding high-speed steel gap grinding comprises the following steps:

[0036] (1) Mix the abrasive material and the metal bond at a volume ratio of 35:65, put them in a three-dimensional mixer for 2 hours and then take them out to pass through a 200-mesh sieve; pass the copper powder used in the transition layer through a 300-mes...

Embodiment 3

[0043] This embodiment provides a grinding wheel for grinding cermets with a gap, which includes a grinding wheel base, a transition layer, and an abrasive layer from the inside to the outside; wherein the raw materials used in the abrasive layer include abrasives and metal bonds; the abrasive is a single crystal Diamond, not nickel-plated, particle size is D126; the metal bond includes the following components by weight: 70 parts of copper powder, 20 parts of tin powder, 5 parts of silver powder, 3 parts of cobalt powder, and 2 parts of nickel powder; the raw materials used for the transition layer are copper powder.

[0044] The preparation method of the above-mentioned grinding wheel for grinding cermet gap grinding comprises the following steps:

[0045] (1) Mix the abrasive material and the metal bond at a volume ratio of 35:65, put them in a three-dimensional mixer for 2 hours and then take them out to pass through a 200-mesh sieve; pass the copper powder used in the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com