Cylinder head gasket with one-way coolant flow valve

A technology of coolant flow and cylinder head, applied in the control of coolant flow, cooling of engine, engine components, etc., can solve problems such as damage to engine components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

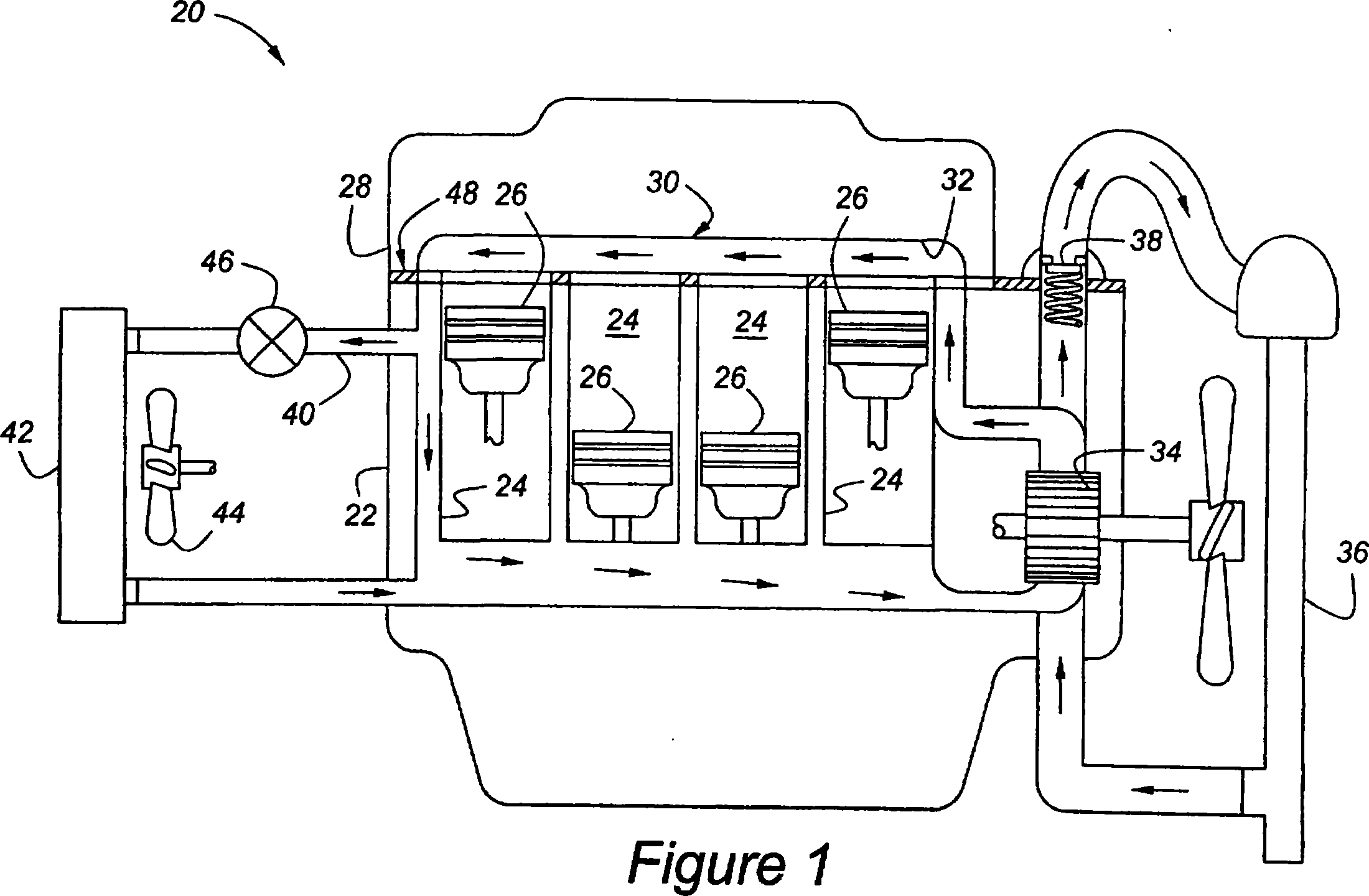

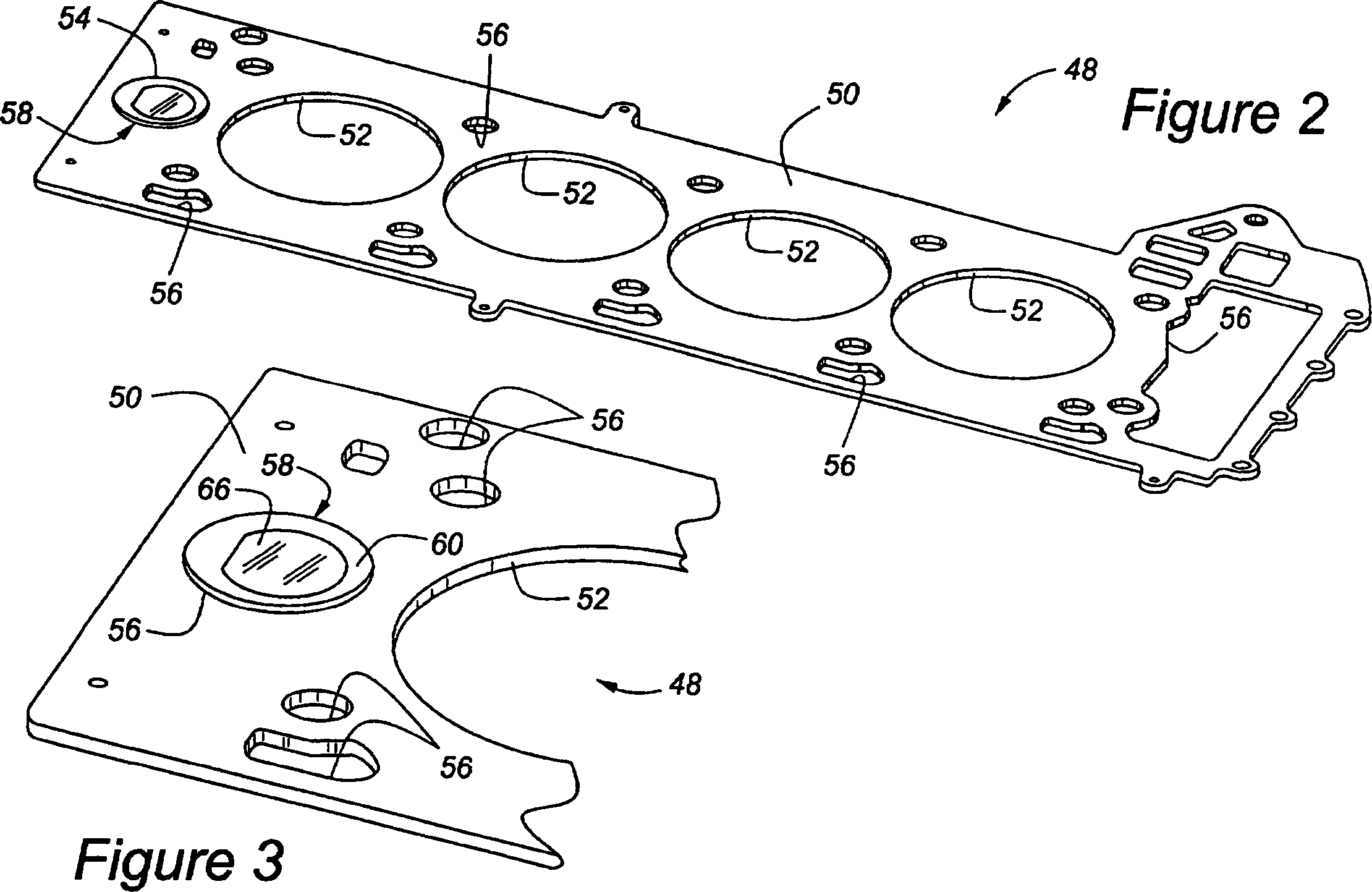

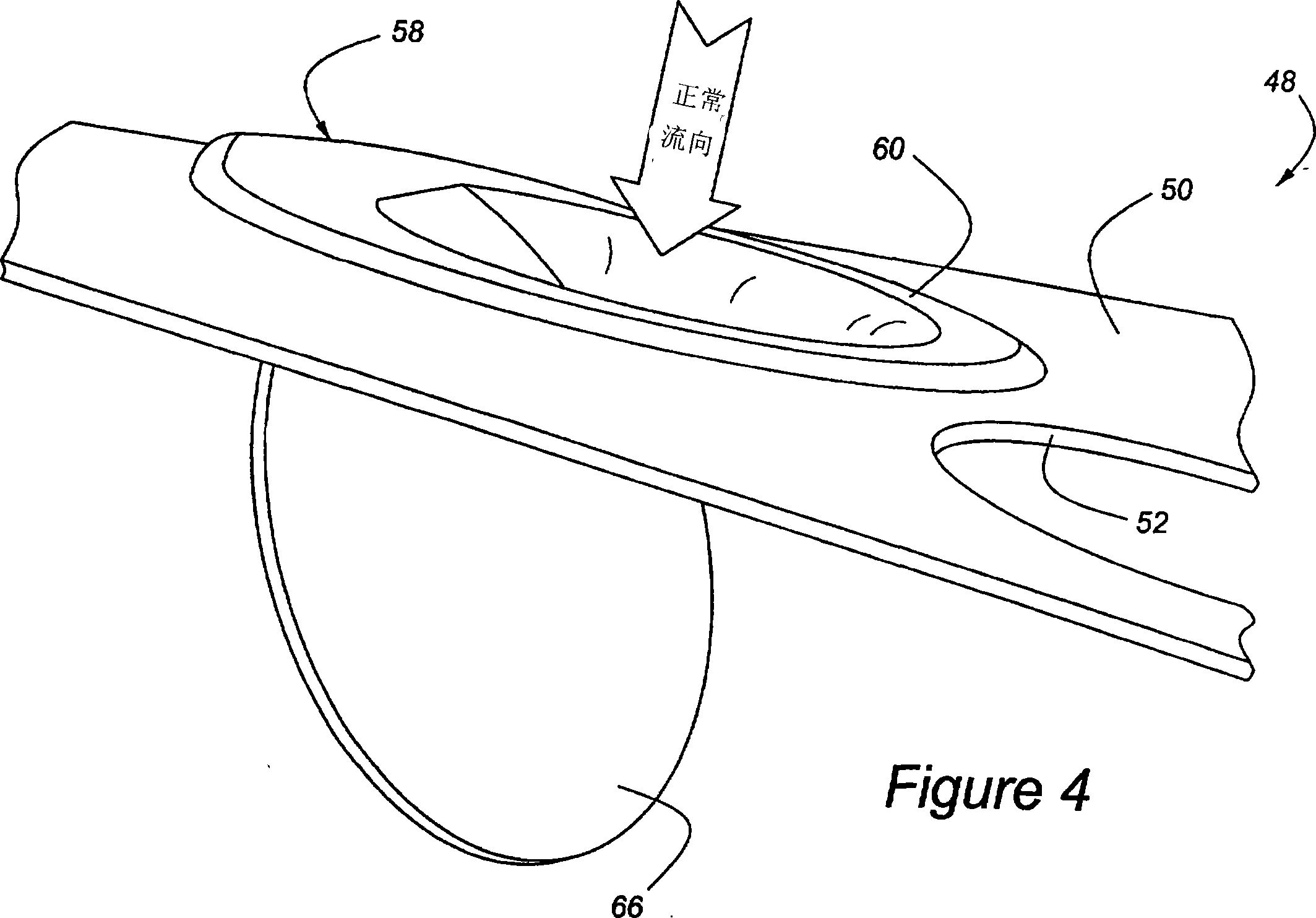

[0022] When referring to the drawings, like numerals designate like or corresponding parts throughout the several views. A liquid cooled internal combustion engine 20 is shown in FIG. 1 including a cylinder block 22 having a plurality of combustion chambers 24 located therein. A piston 26 reciprocates in each combustion chamber 24 in two or four strokes, generating power through the combustion process while generating large amounts of heat as a by-product. A cylinder head 28 is secured to the cylinder block 22 and covers each combustion chamber 24 to seal combustion gases.

[0023] To handle the substantial amount of heat generated during combustion, a cooling system 30 is, in part, integrated with block 22 and cylinder head 28 . The cooling system 30 includes a bypass flow passage 32 for allowing coolant to flow from the cylinder head 28 to the cylinder block 22 under the action of a pump 34 . Excess heat in the coolant is transferred via a heat exchange radiator 36 . A fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com