Interface circuit

A technology of interface circuit and conversion circuit, applied in the field of interface circuit, can solve the problem that it is difficult to reduce the manufacturing cost of control substrate, and achieve the effect of simple structure and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

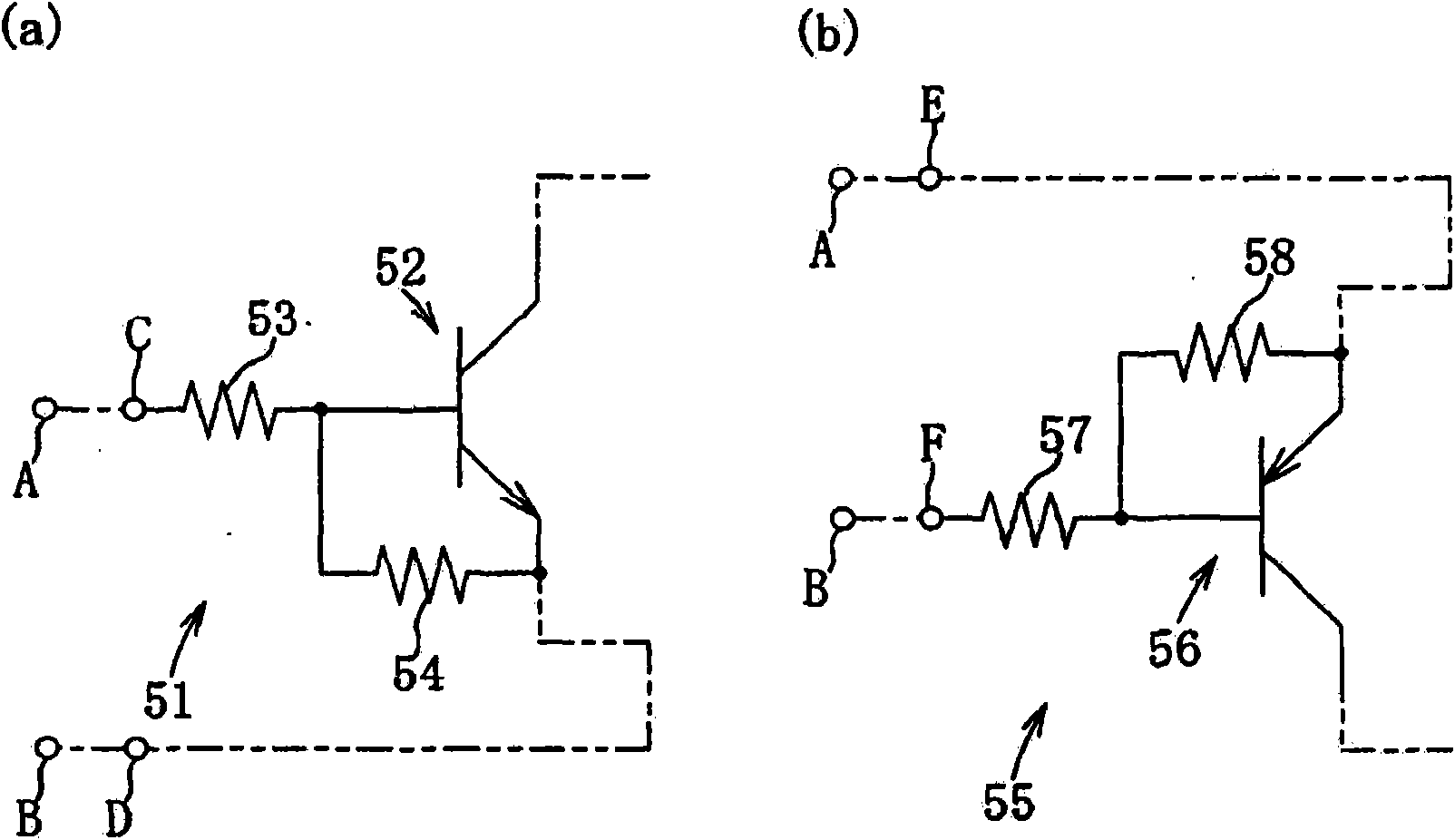

[0043] Hereinafter, the present invention will be described in detail with reference to the drawings showing a preferred embodiment 1. FIG.

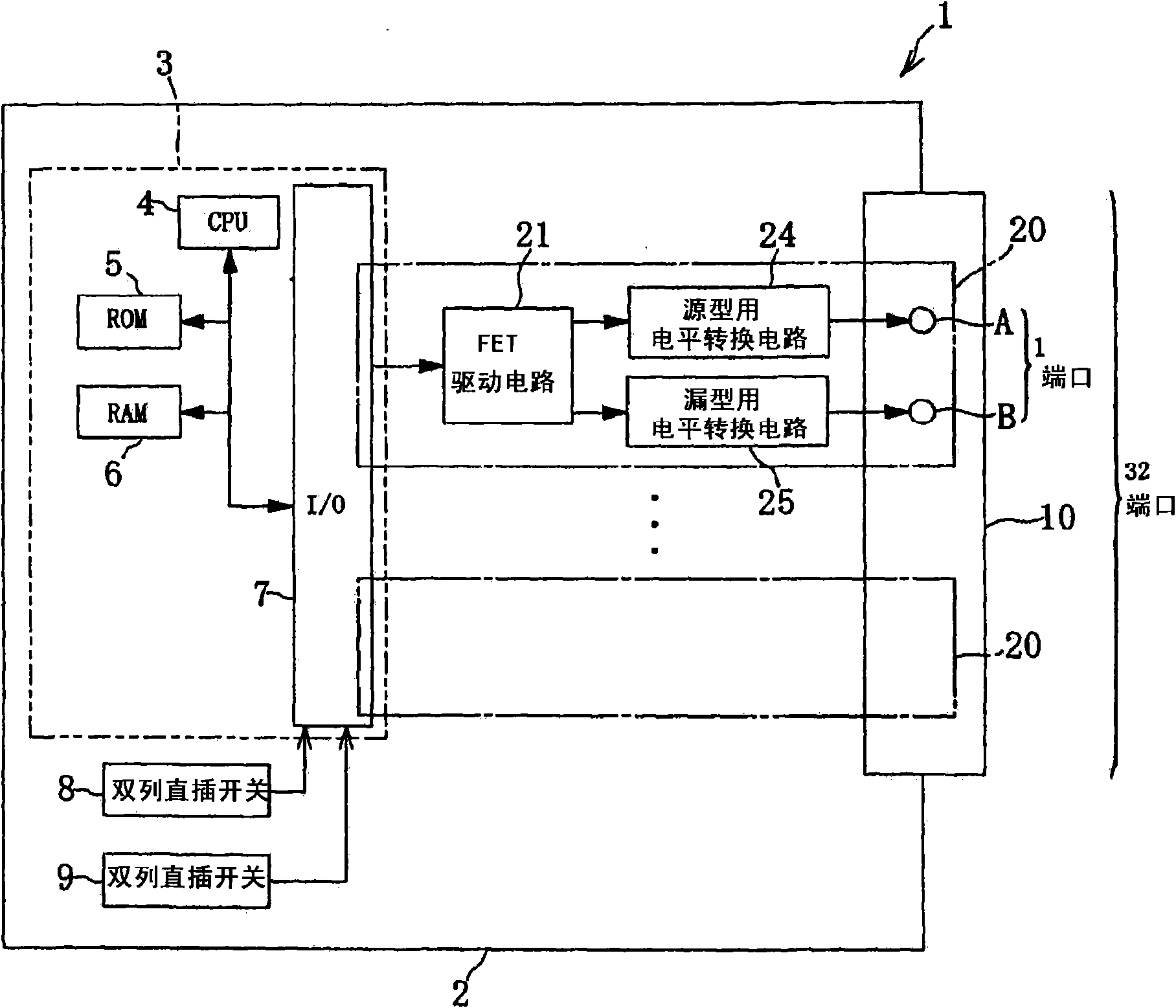

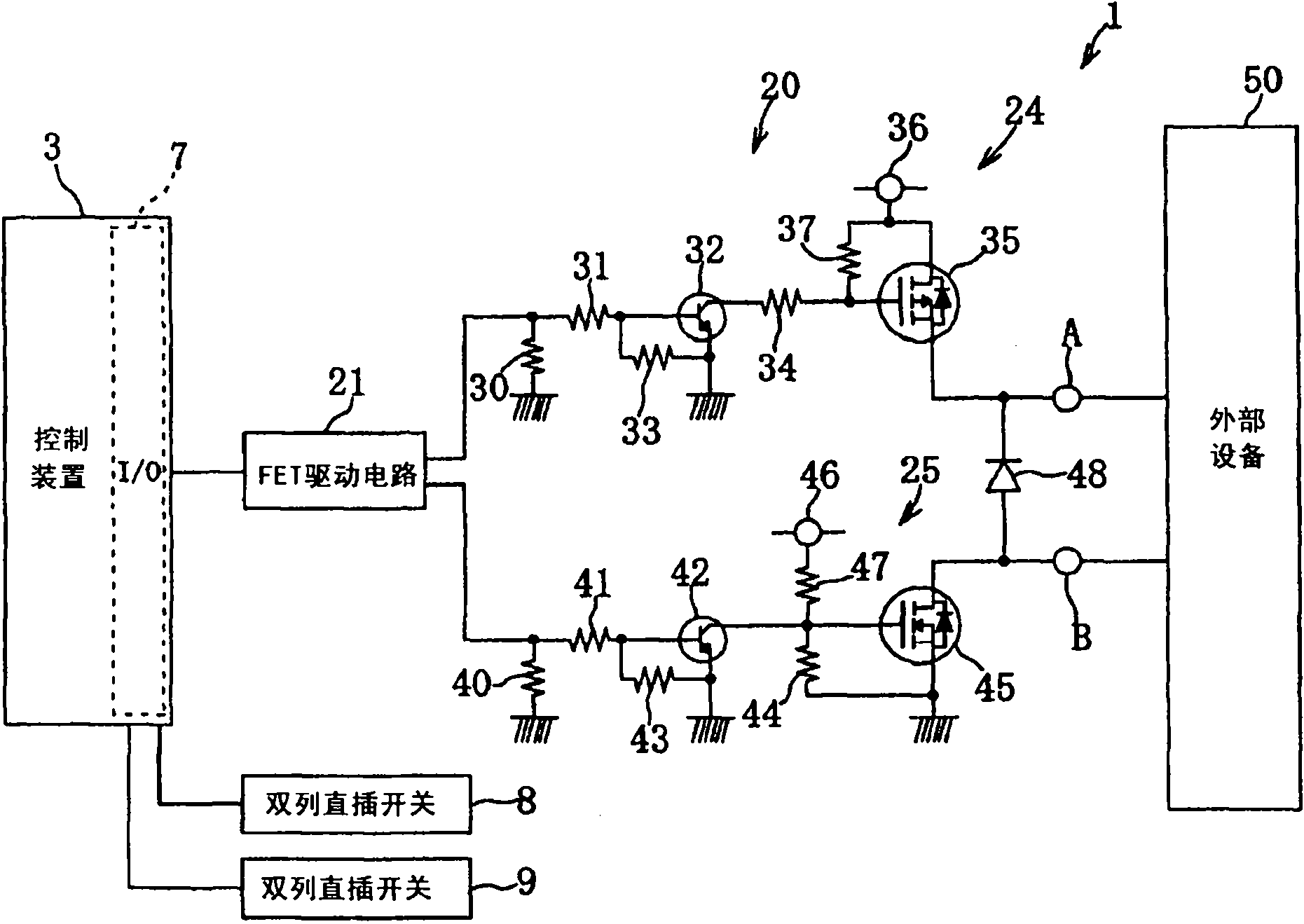

[0044] The output interface circuit 1 is set in the numerical control device of the machine tool. like figure 1 , figure 2 As shown, the output interface circuit 1 has a control device 3 , 32 output circuit units 20 , two dip switches (selection switches) 8 and 9 , and a terminal board 10 . The terminal board 10 includes 32 ports. Each port can be configured with two terminals. Terminal A and terminal B described later are disposed on this port.

[0045] The output interface circuit 1 is mounted on the substrate 2 . The control device 3 has a CPU 4 , a ROM 5 , a RAM 6 , and an input / output interface (I / O) 7 . The DIP switches 8 and 9 and the FET drive circuit 21 are connected to the input / output interface 7 . The control device 3 controls the drive of the FET drive circuit 21 described later in accordance with the selection made ...

Embodiment approach 2

[0084] Hereinafter, the present invention will be described in detail with reference to drawings showing a preferred embodiment 2. FIG.

[0085] according to Image 6 Next, the configuration of the input interface circuit 11 will be described.

[0086] The input interface circuit 11 is provided in the numerical control device of the machine tool. The input interface circuit 11 has a control device 13 , 32 input circuit units 200 , two dip switches (selection switches) 18 and 19 , and a terminal board 60 . The terminal board 60 includes 32 ports. Each port can be configured with two terminals. Terminals J and K described later are disposed on this port.

[0087] The input interface circuit 11 is installed on the substrate 12 . The control device 13 has a CPU 14 , a ROM 15 , a RAM 16 , and an input / output interface (I / O) 17 . The control device 13 controls the FET drive circuit 210 according to the selection made by the dip switches 18 and 19 . The input / output interface ...

Embodiment approach 3

[0129] Hereinafter, the present invention will be described in detail with reference to the drawings showing a preferred third embodiment.

[0130] according to Figure 11 The configuration of the input / output interface circuit 300 will now be described.

[0131] The input / output interface circuit 300 provided in the machine tool numerical control device includes an output interface circuit 1 and an input interface circuit 11 .

[0132] The output interface circuit 1 has a control device 3 , 32 output circuit units 20 , two dip switches 8 and 9 , and a terminal board 10 . The terminal board 10 includes 32 ports. Each port can be configured with two terminals. Terminal A and terminal B are arranged on this port.

[0133] The output interface circuit 1 is mounted on the substrate 2 . The control device 3 has a CPU 4 , a ROM 5 , a RAM 6 , and an input / output interface (I / O) 7 . The DIP switches 8 and 9 and the FET drive circuit 21 are connected to the input / output interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com