Device for grinding and cutting wafer

A grinding, wafer technology, applied in the direction of grinding device, grinding/polishing equipment, grinding machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

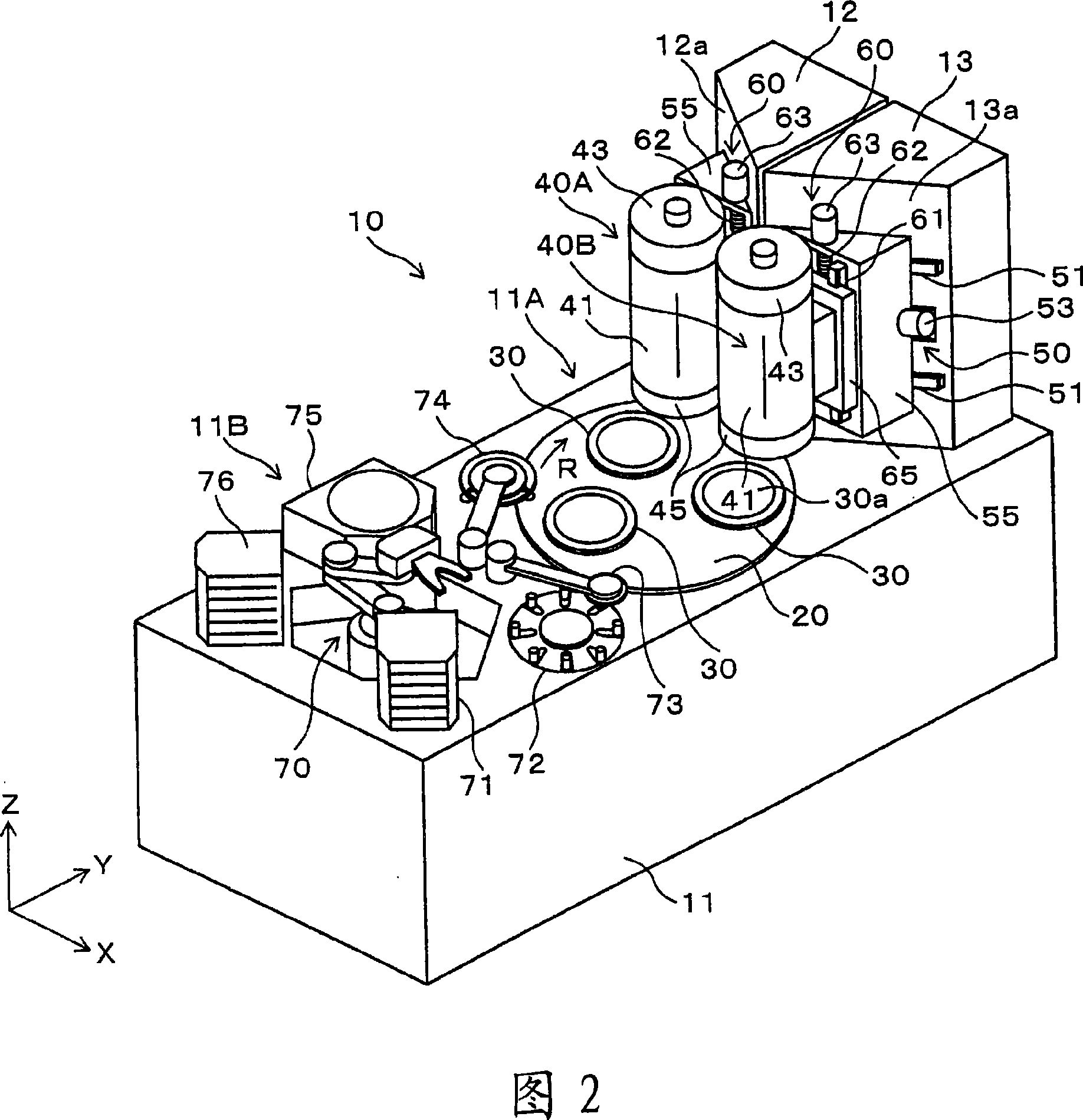

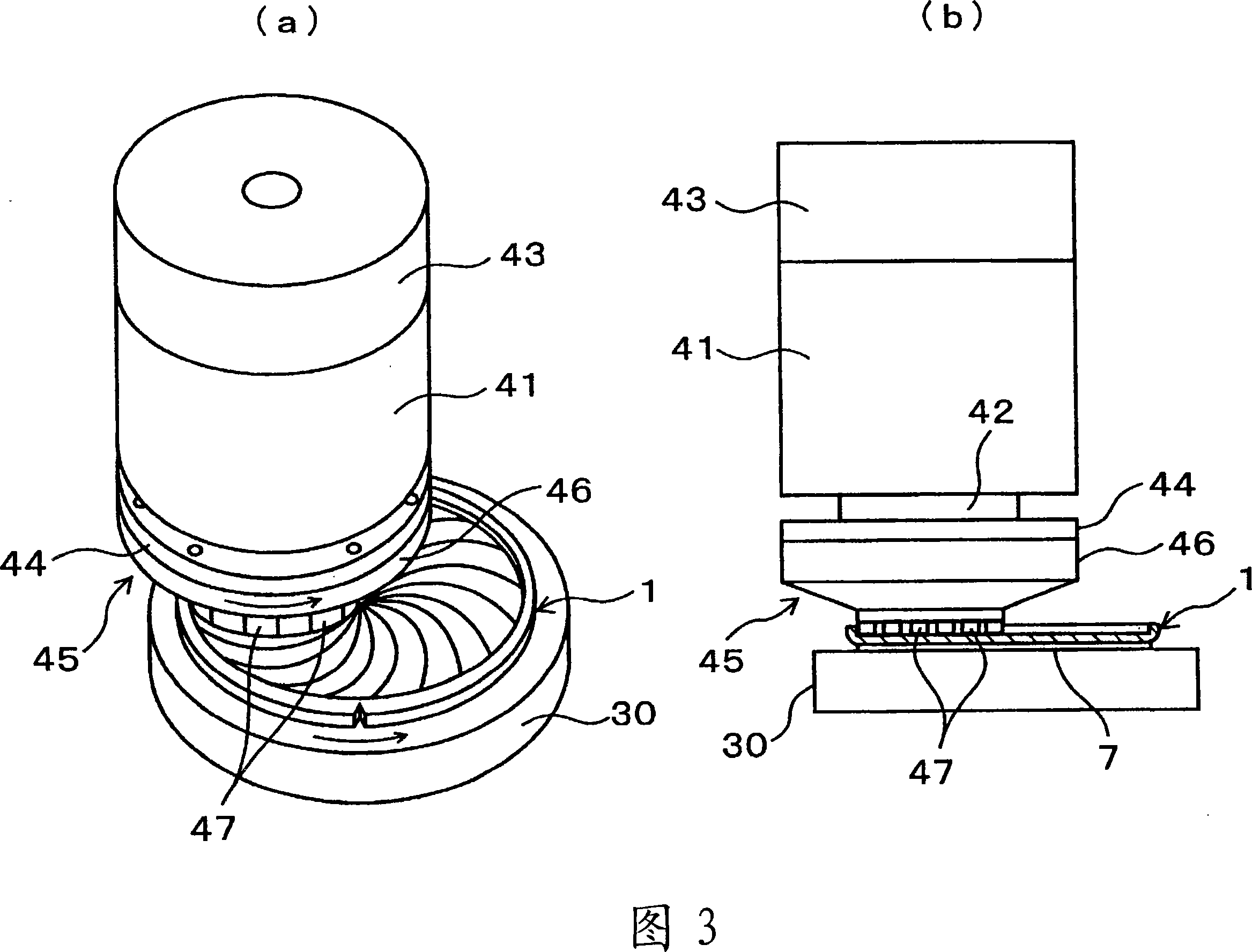

[0035] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

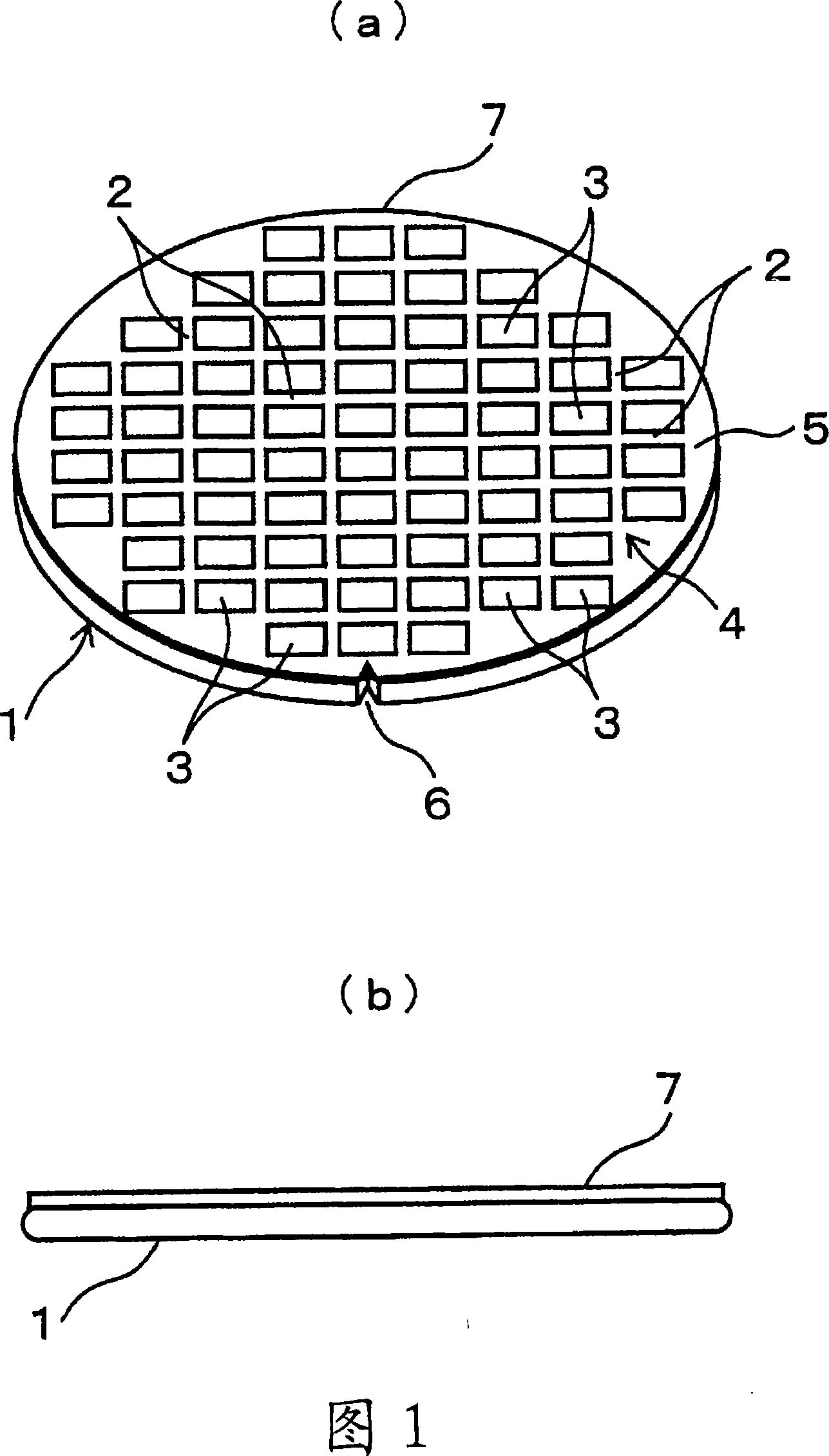

[0036] (1) Semiconductor wafer

[0037] Reference numeral 1 in FIG. 1 denotes a disk-shaped semiconductor wafer (hereinafter, simply referred to as a wafer) having recesses formed on the back surface thereof by a wafer grinding apparatus according to one embodiment. The wafer 1 is a silicon wafer or the like, and its thickness before processing is, for example, about 600 to 700 μm. On the surface of the wafer 1, a plurality of rectangular semiconductor chips 3 are divided by grid-like dividing lines 2, and IC (Integrated circuit: integrated circuit), LSI (Large Scale Integration: large-scale integration) are formed on the surface of these semiconductor chips 3. circuit) and other electronic circuits not shown in the figure.

[0038] A plurality of semiconductor chips 3 are formed in an approximately circular-shaped device formation region 4 concentric with the wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com