Bamboo-wood structure floor

A bamboo, wood and floor technology, applied in building structures, floors, buildings, etc., can solve the problems of large amount of adhesive, high cost, inability to use small materials and other problems, achieve natural elasticity and reduce production costs , The effect of saving solid wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

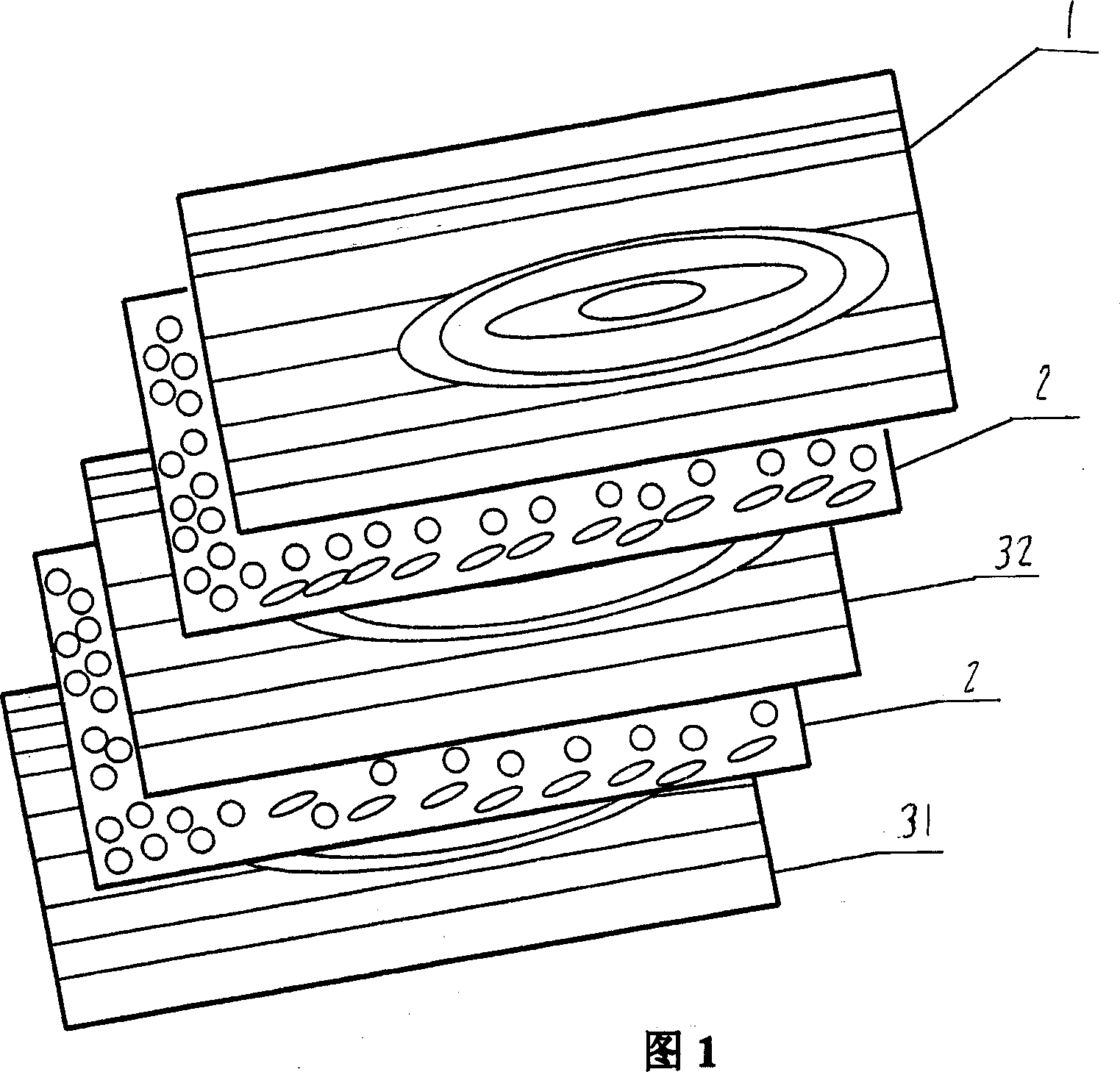

Image

Examples

Embodiment

[0034] A. Add man-made fiber fabric

[0035] ①. The surface layer is made of 2mm bamboo chips, and the second layer is added with cotton cloth 35g / m 2 , the third layer is glulam with a thickness of 14mm, and the fourth layer is added with cotton cloth 35g / m 2 , the fifth floor is made of 2mm solid wood board, after gluing and hot pressing, the thickness of the whole board is 18mm, the test report is as follows:

[0036] Test items

unit

Standard value

test result

MPa

≥4000

7200

Dip Peel Test

MM

The cumulative amount of adhesive layer opening does not exceed 1 / 3 of the adhesive layer

0

[0037] Formaldehyde emission

Mg / L

≤1.5

0.8

moisture content

%

5~14

11

static bending strength

MPa

ave≥30; min≥24

Ave=66; min=53

[0038] ②, the surface layer is made of 2mm bamboo chips, and the second layer is added with polyester cloth 190g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com