Wood floor

A wood structure and floor technology, which is applied to building structures, wood layered products, floors, etc., can solve the problems of large amount of adhesive, high cost, and inability to use secondary materials and small materials, etc., to achieve natural and real elasticity, The effect of reducing production costs and saving solid wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

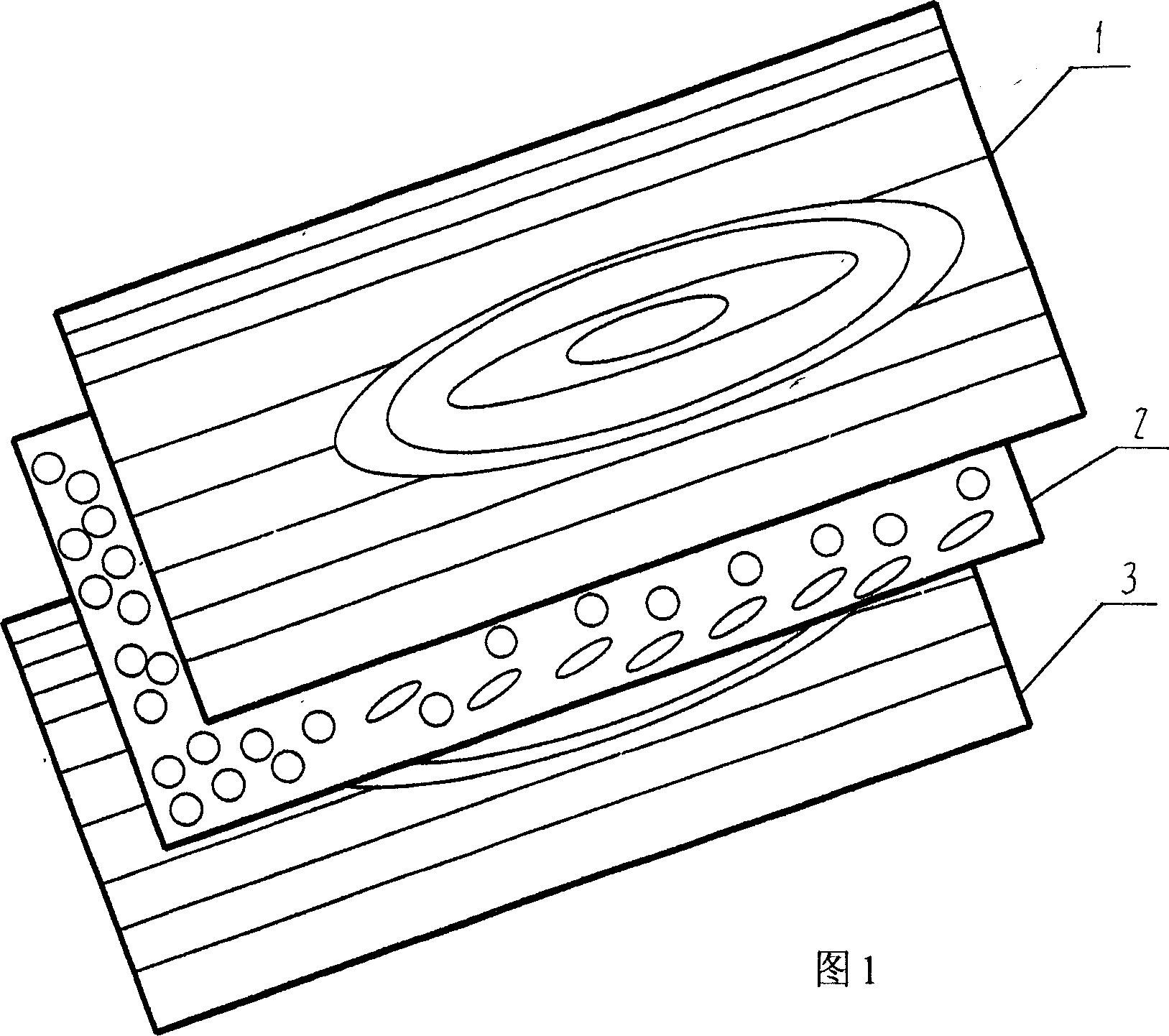

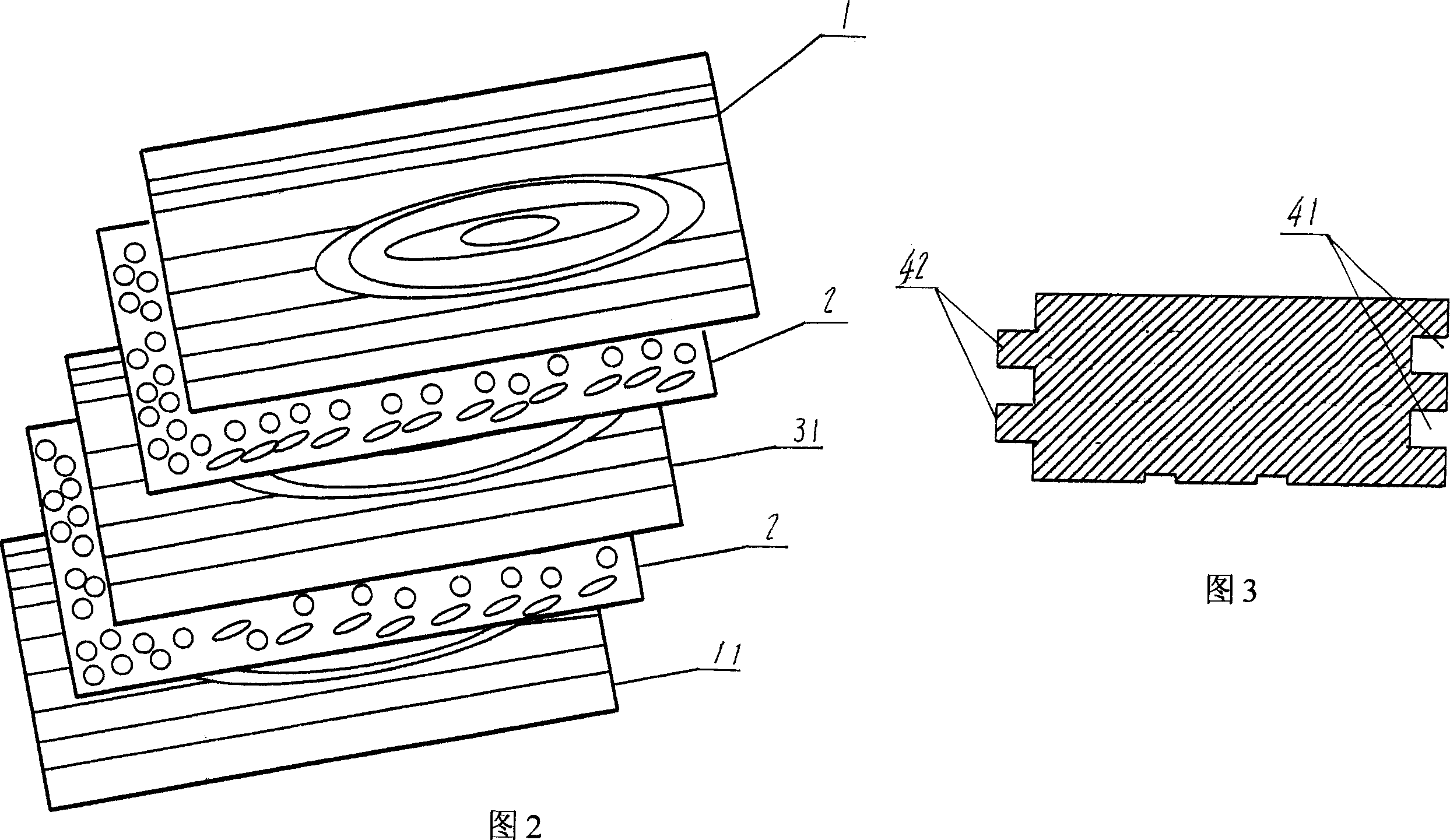

[0042] (1), three-tier structure

[0043] A. Add man-made fiber fabric

[0044] ①. The surface layer is made of 0.8mm solid wood whole board, and the core layer is added with cotton cloth 25g / m 2 , the bottom layer is glulam with a thickness of 16mm. After gluing and hot pressing, the thickness of the whole floor is 16mm. The test report is as follows:

[0045] Test items

[0046] ②. The surface layer is made of 2.5mm solid wood board, and the core layer is added with polyester cloth 30g / m 2 , Nylon cloth 60g / m 2 , the bottom layer is glulam with a thickness of 13mm. After gluing and hot pressing, the thickness of the whole floor is 14mm. The test report is as follows:

[0047] Test items

[0048] ③. The surface layer is made of 4mm solid wood board, and the core layer is made of non-woven fabric 330g / m 2 , the bottom layer is glulam with a thickness of 12mm. After gluing and hot pressing, the thickness of the whole floor is 16mm. The test report is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com