Film feeding mechanism for film type camera

A film conveying mechanism and film technology, applied in the field of film conveying mechanism, can solve the problems such as the difficulty of film conveying in the same amount as the camera shooting cycle, and achieve the effects of compact structure, large transmission torque and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

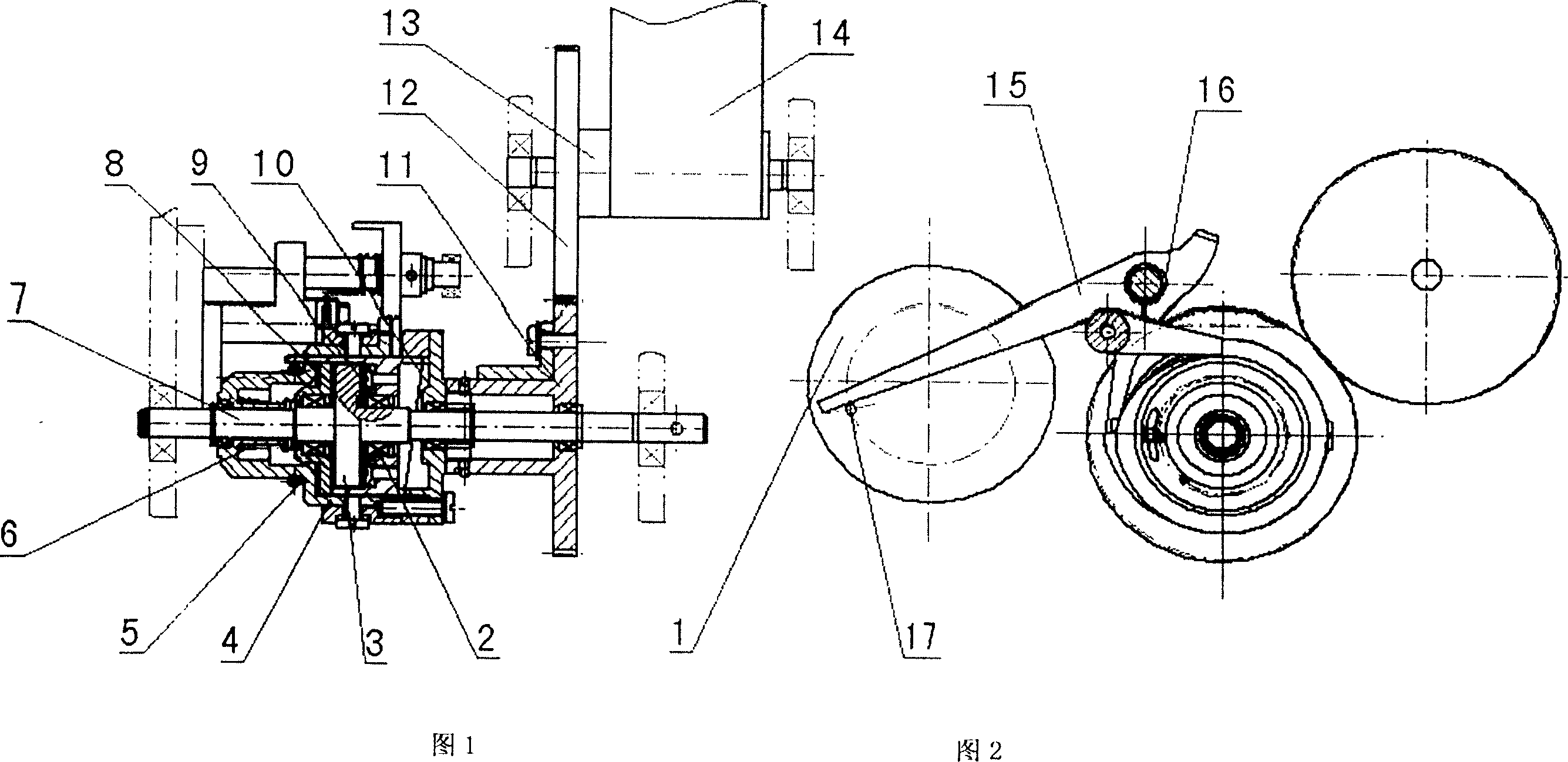

[0018] One week electromagnetic coil 1, transmission shaft 7, A gear 11, B gear 12, measuring sheet roller 13, stop hook 15 are respectively fixed on the support frame structure by bearing 2.

[0019] A transmission friction disc 3, a clutch housing 4, a transition piece 8, B transmission friction disc 9, C transmission friction disc 10, and A gear 11 are respectively installed on the transmission shaft 7 through the bearing 2.

[0020] Stop the long handle of hook 15 and contact with the dial pin 17 on the electromagnetic coil 1 of a week, stop the breach contacting with the flange on the clutch housing 4 of a week, and stop the clutch housing 4 rotations of a week.

[0021] Stop hook spring 16 one end links to each other with stop hook 15, and the other end is fixed on the support frame, and is wound on the stop hook 15, guarantees that the long handle of stop hook 15 leans against on the dial pin on the week electromagnetic coil 1 all the time. When one week electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com