Centrifugal pellet dryer screen

一种颗粒干燥、干燥机的技术,应用在离心机、烘干机、有旋转式转鼓的离心机等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Although several preferred embodiments of the present invention have been described in detail, it should be understood that the scope of the present invention is not limited to the details of the structure and component arrangement listed in the following description or shown in the drawings. The present invention can adopt other embodiment forms, and can be practiced or executed in a variety of ways. In addition, in the described preferred embodiments, specific terminology will be used for clarity. It should be understood that each specific term includes all technical equivalents that use similar methods to achieve similar operations.

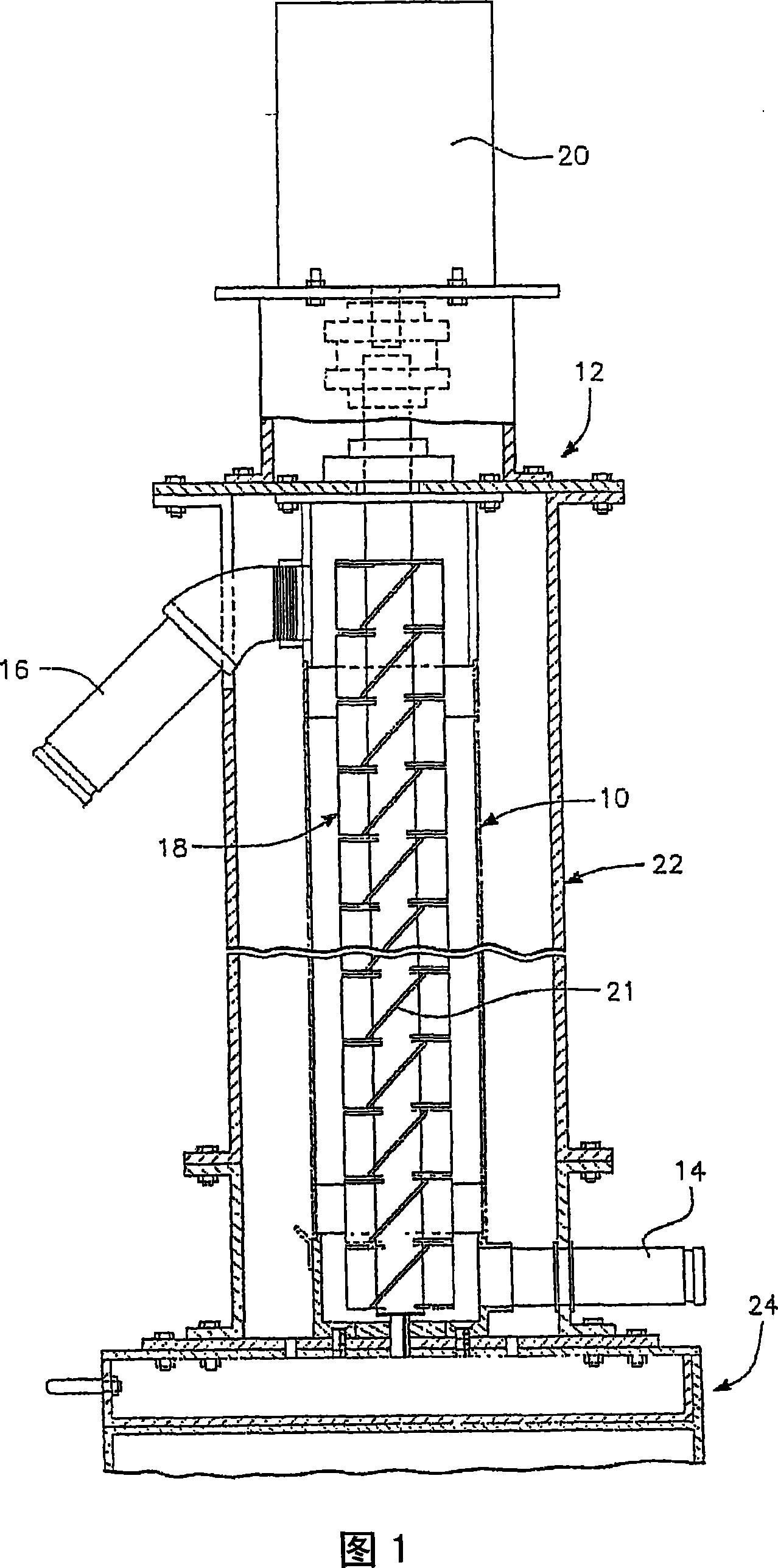

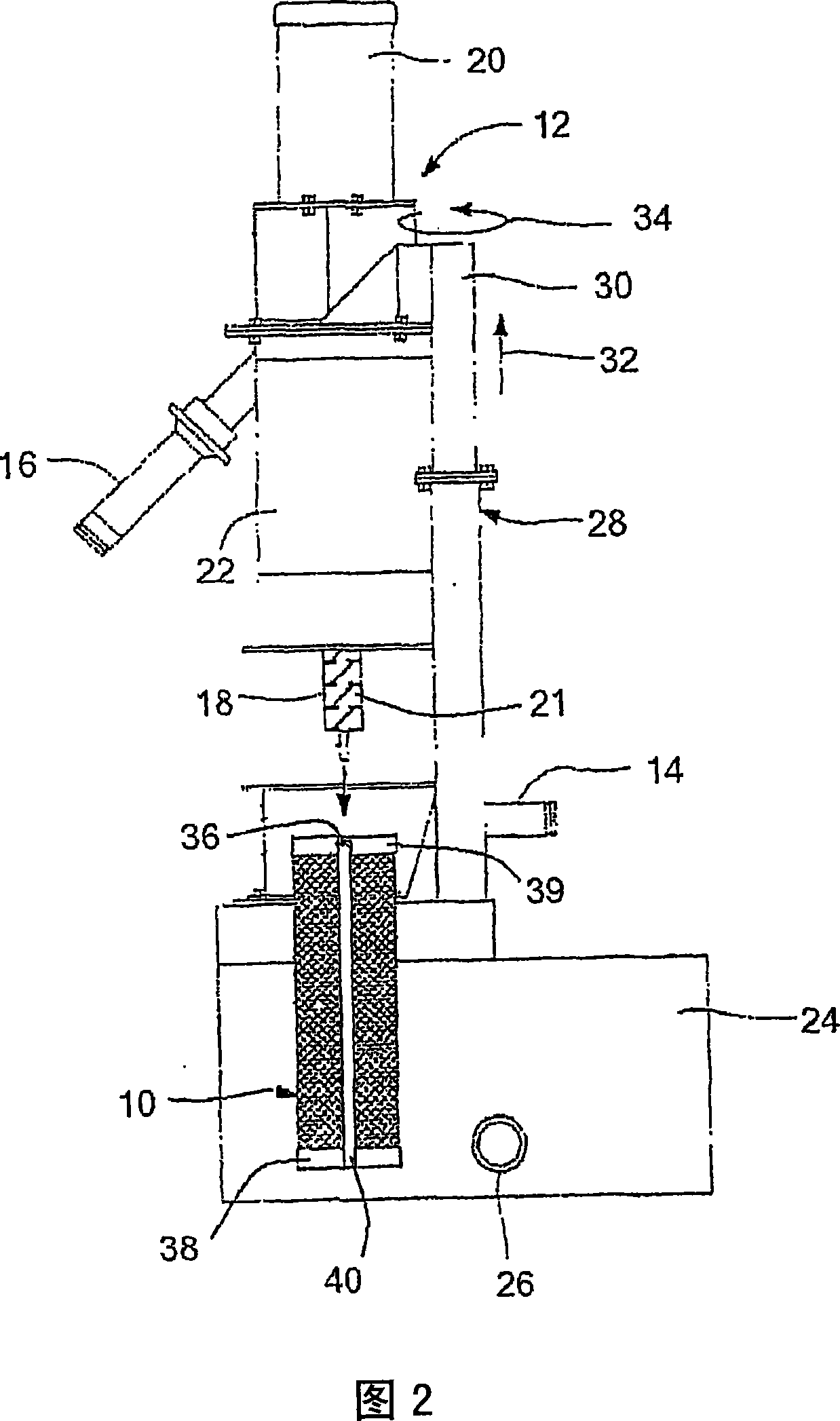

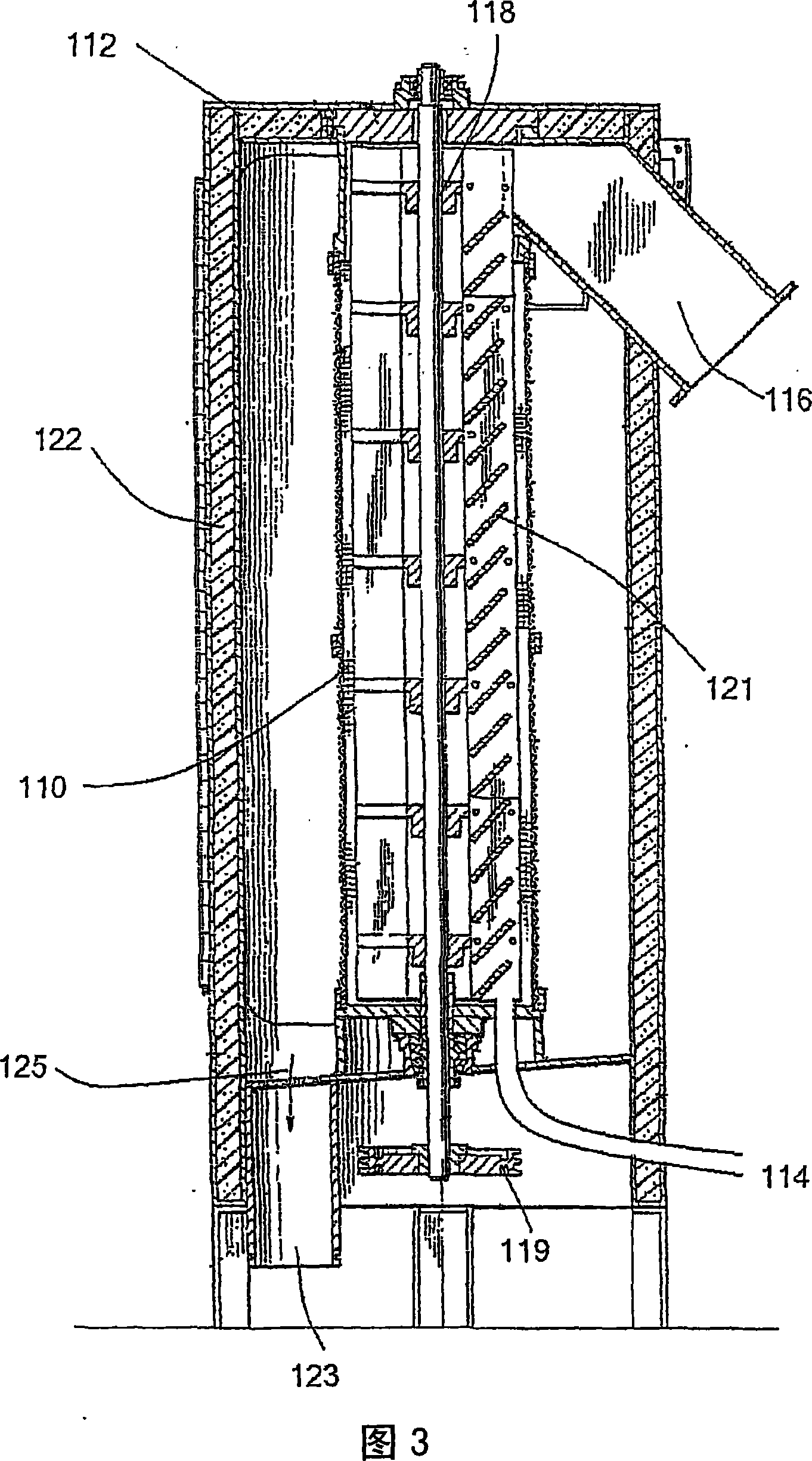

[0054] With particular reference to FIG. 1 of the drawings, the polymer particles and microparticle dryer screens of the present invention are generally indicated by the reference numeral 10. FIG. 1 discloses the combination of the particle sieve 10 in a typical centrifugal particle dryer, which is disclosed in detail in US Patent No. 6,237...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com