Stretching jack

A technology for tensioning jacks and cylinders, applied in the direction of lifting devices, etc., can solve the problems of high cost of the prestressed tendon tensioning system, large anchor holes of the tensioning system, and long working length of the tensioning bars, etc. Small stress loss and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

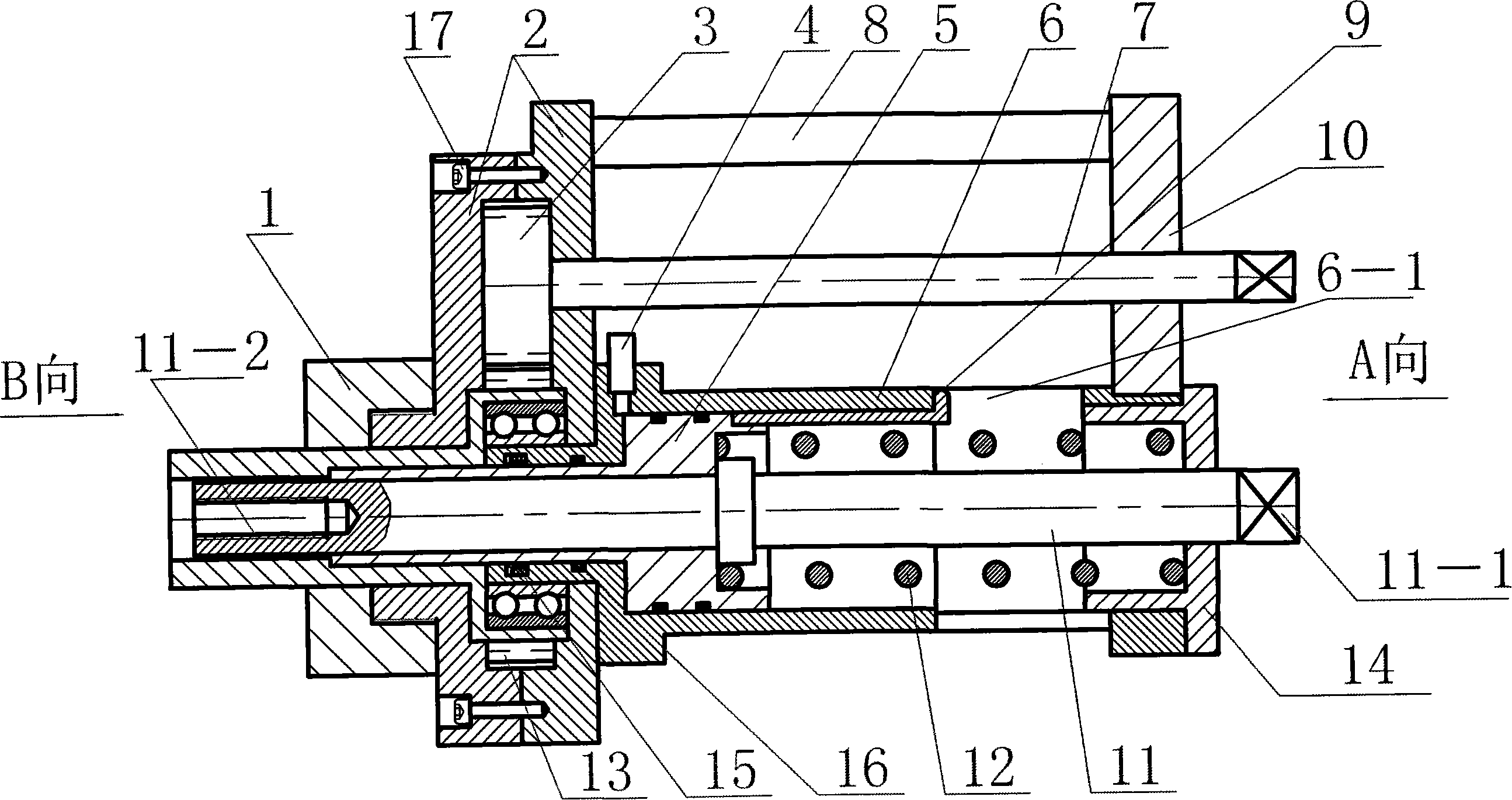

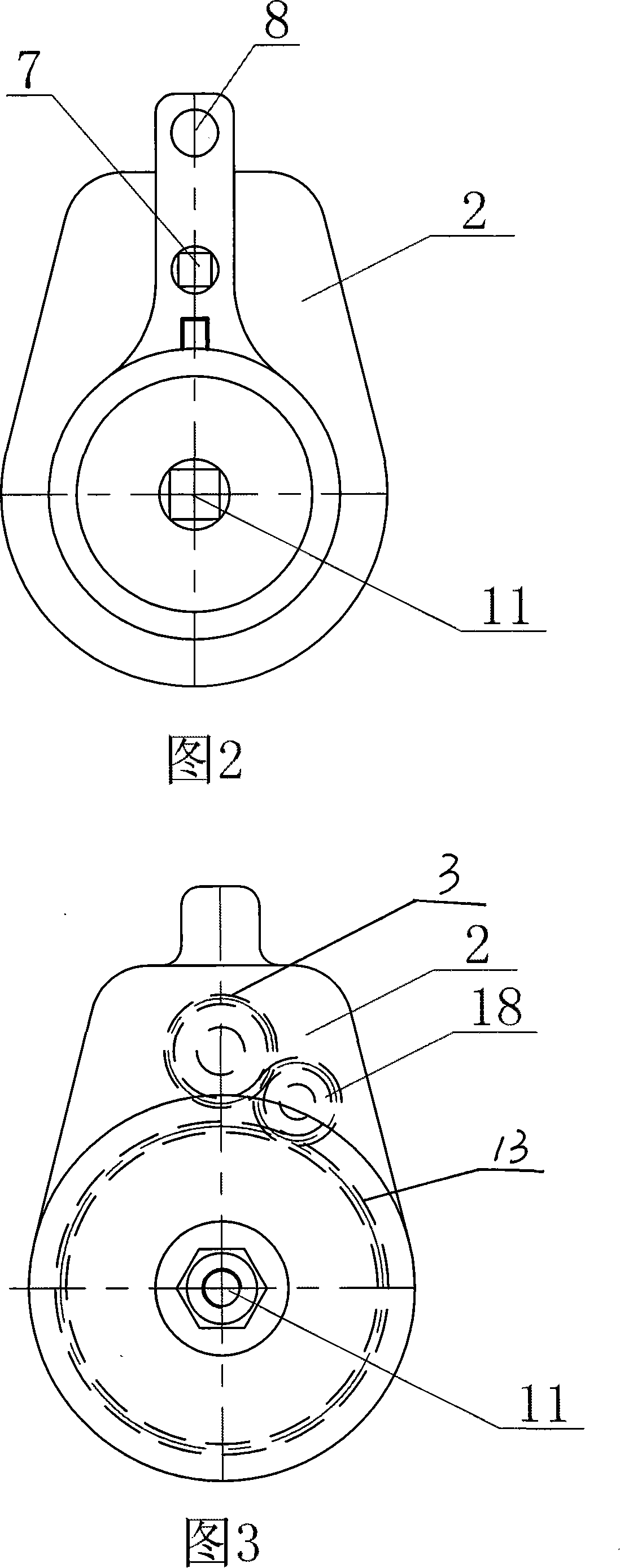

[0024] As shown in Figure 1-3, a tension jack includes a cylinder body 6, and one end of the cylinder body 6 with a support 10 is connected with an end cover 14, which is convenient for installing parts in the inner cavity of the cylinder body, and the other end of the cylinder body 6 passes through The bearing is connected with a large gear 13, one end of the large gear 13 has a sleeve, and one side of the large gear 13 is provided with an intermediate wheel 18 meshing with it. The end of the gear shaft 7 with a square head is installed on the support 10, and the gear shaft 7 The other end of the pinion gear 3 is fixedly connected with the intermediate wheel 18, and the pinion gear 3 meshing with each other, the intermediate wheel 18 and the large gear 13 are installed in the gear box 2, and the gear box 2 is connected by a hexagon socket. It is formed by connecting screws 17. The sleeve of the large gear 13 is fitted with a load-bearing sleeve 1, and the inner ring of the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com