Method for manufacturing natural detaching surface outside edge brick

A manufacturing method and technology for exterior wall corners, applied in building construction, covering/lining, construction, etc., can solve the problems of high cost, high glue price, high labor cost, achieve a high degree of automation, beautiful appearance and improve production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Production of (128+80)*20*13mm exterior wall corner tiles

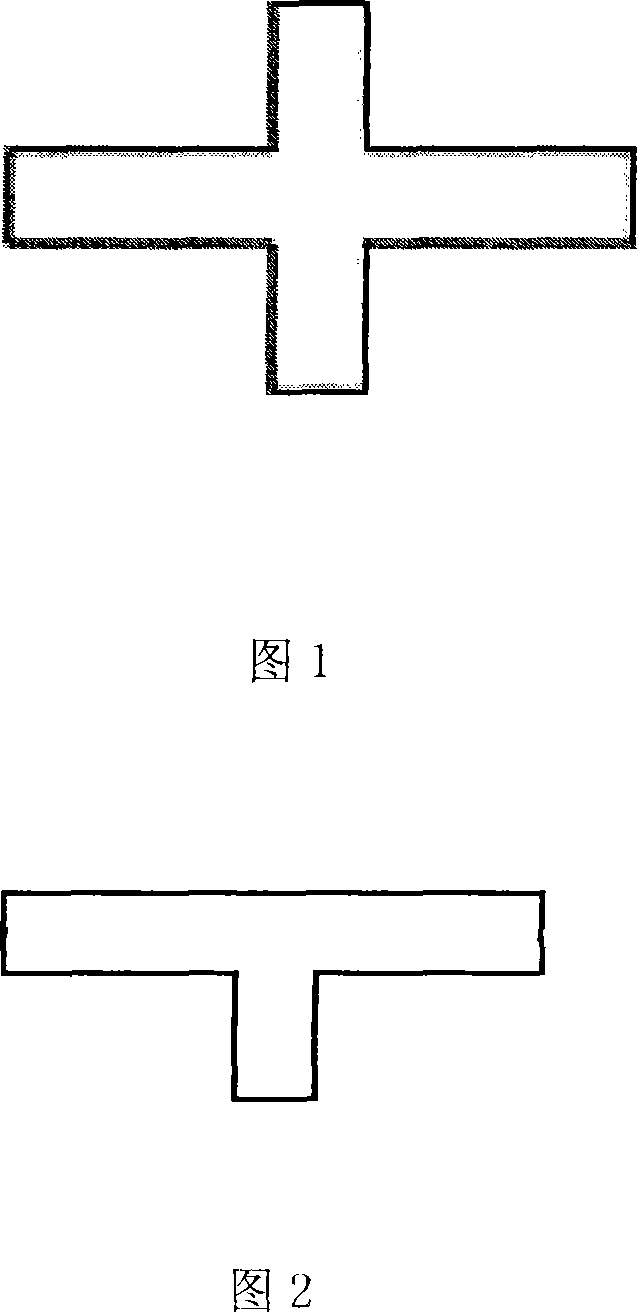

[0028] 1. The basic shape of the mold working surface is shown in Figure 1. It is designed as a "cross" shape, that is, the horizontal working surface of the upper mold is a "cross" shape, and the horizontal working surface of the lower mold is a "cross" shape that matches the upper mold. The surface has uneven surface.

[0029] 2. Molding: The general molding technology is adopted, and the technical parameters are: moisture: 6.5%; molding pressure: 20mpa; molding thickness: 21mm.

[0030] 3. Splitting and peeling: Splitting is carried out with a splitting tool. The splitting tool is a double-sided opening type splitting knife with different angles, and the splitting tool uses a 10° opening. The shape of the cutter is a "cross" shape, and it is split once. When splitting, the cutter is aligned with the center of the brick (the dotted line in Figure 2), and then the cutter is split and peeled by hydraulic impact equ...

Embodiment 2

[0035] Production of (125+60)*40*15mm exterior wall corner tiles

[0036] 1. The basic shape of the mold working surface is shown in Figure 1. It is designed as a "cross" shape, that is, the horizontal working surface of the upper mold is a "cross" shape, and the horizontal working surface of the lower mold is a "cross" shape that matches the upper mold. The surface is flat.

[0037] 2. Molding: The general molding technology is adopted. The technical parameters are: moisture: 6.0%, molding pressure: 25mpa, molding thickness: 41mm.

[0038] 3. Splitting and peeling: Splitting is carried out with a splitting tool. The splitting tool is a double-sided opening riving knife with different angles, and the splitting tool uses a 90° opening. The shape of the cutter is "one", and it adopts double splitting. After the cutter is aligned with the center of the brick (the dotted line in Fig. 3) during splitting, mechanical equipment acts on the cutter to perform secondary splitting and peelin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap