Critical refraction longitudinal wave detection component inside tangential stress assistant device

A technology for detecting components and critical refraction, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions, achieving good general performance and large amplitude effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

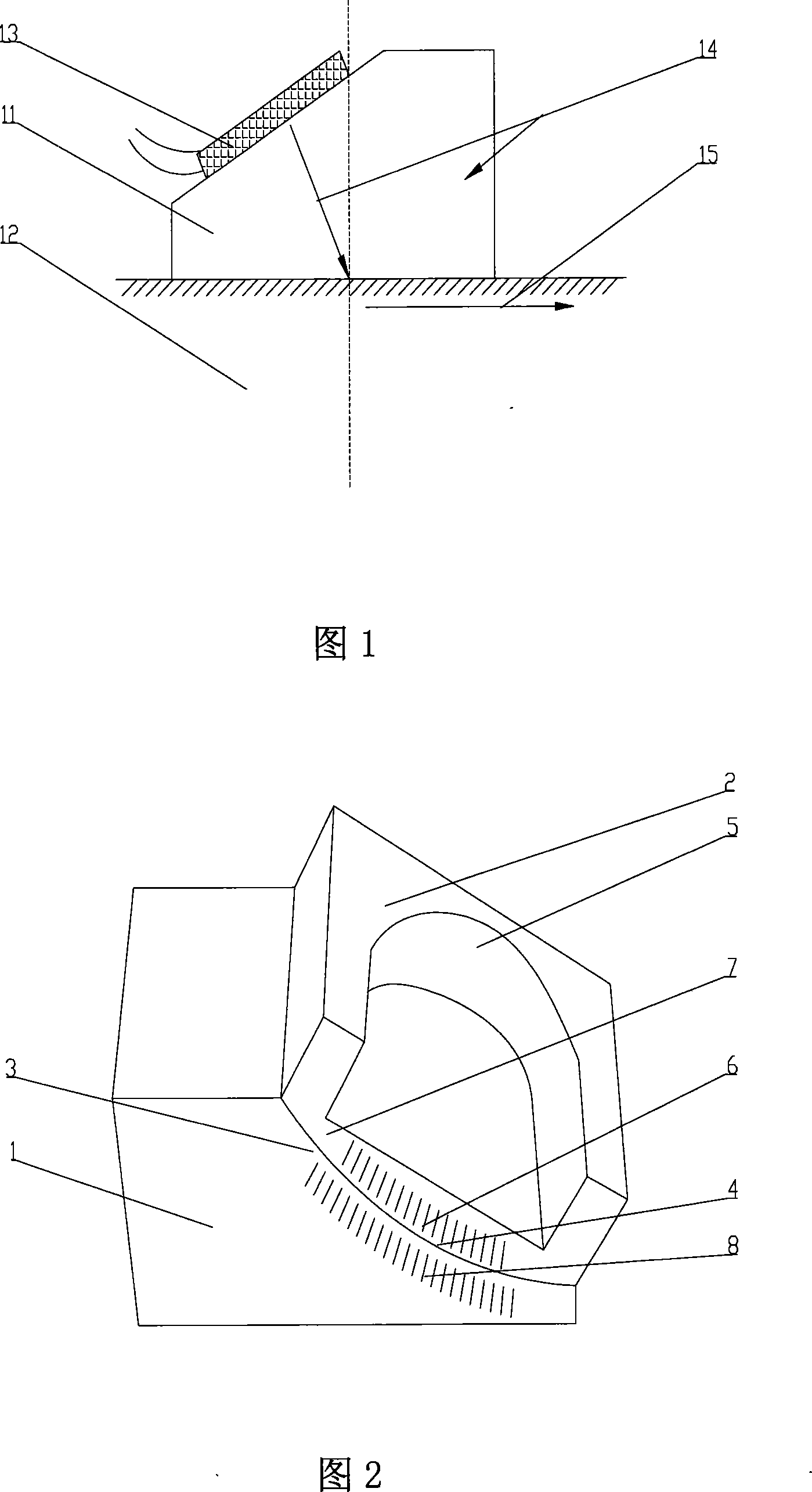

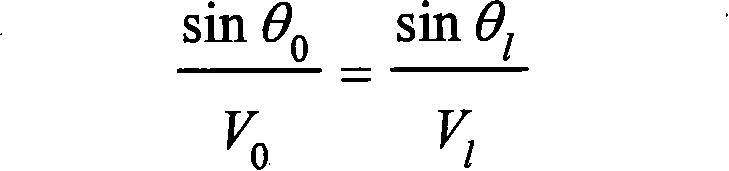

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0031] As shown in Figure 2, the present invention is made of two parts, the bottom 1 of organic glass, the upper part 2 of organic glass. The lower part 1 is shaped like a dam with a large bottom and a small top, and the upward slope forms a concave cylindrical surface 3 . Top 2 becomes U-shaped 5, and one side is open, is convenient to change the receiving and emitting probe of ultrasonic wave, and another side 7 is closed, and one side of sealing becomes outward protrusion cylinder 4. The protruding cylindrical surface 4 of the upper part 2 coincides with the concave cylindrical surface 3 of the lower part 1 , and the upper part 2 can slide on the concave cylindrical surface 3 of the lower part 1 . Fill high-viscosity liquid coupling agent between the upper part 2 and the lower part 1 to eliminate the gap in the contact area and avoid the attenuation caused by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com