Technology for methanation processing consumer waste step by step and bioreactor

A technology of bioreactor and methanogenic reactor, which is applied in the field of bioreactor for step-by-step methanation treatment of domestic waste, which can solve the problems affecting the stabilization process of landfill waste, increasing operating costs, and uneven fermentation process , to achieve the effect of promoting rapid stabilization process, accelerating stabilization, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

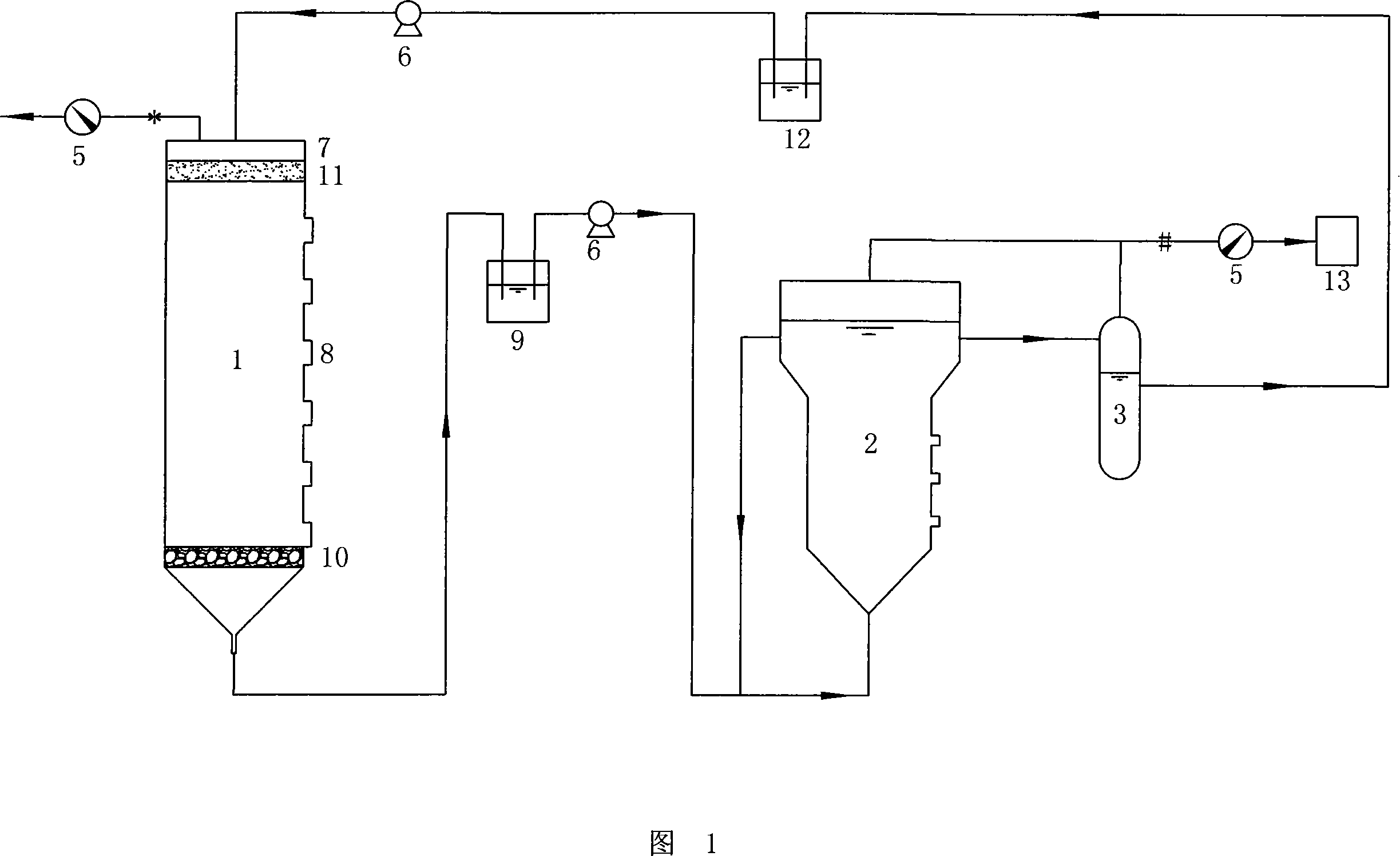

[0017] As shown in Figure 1, a bioreactor for step-by-step methanation of domestic waste includes a sanitary landfill 1, and the bottom leachate outlet of the sanitary landfill 1 is connected to the methane-producing reactor through a water collection bottle 9 and a peristaltic pump 2. The top air chamber 7 of the methanogenic reactor 2 is connected to the gas collection bag, the water outlet of the methanogenic reactor 2 is connected to the three-phase separator 3, and the liquid passage of the three-phase separator 3 is connected to the water collecting bottle 12 and the peristaltic pump 6 The top leachate water inlet of the sanitary landfill 1 is connected, and the gas passage is connected to the gas collection bag 13 .

[0018] The methanogenic reactor 2 is provided with a circulation pipeline that returns to the water inlet pipe at the bottom.

[0019] The bottom of the sanitary landfill 1 is provided with a gravel layer 10 to facilitate the smooth discharge of leachate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com