Optical fibre connecting mechanism

An optical fiber connection and optical fiber technology, which is applied in the field of optical fiber connection devices and optical fiber connection components, can solve the problems of high manufacturing cost, complex product structure, and unfavorable products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] An optical fiber connection device and a method for using the connection device according to an embodiment of the present invention will be described below with reference to the accompanying drawings. Throughout the drawings, the same parts are denoted by the same reference numerals.

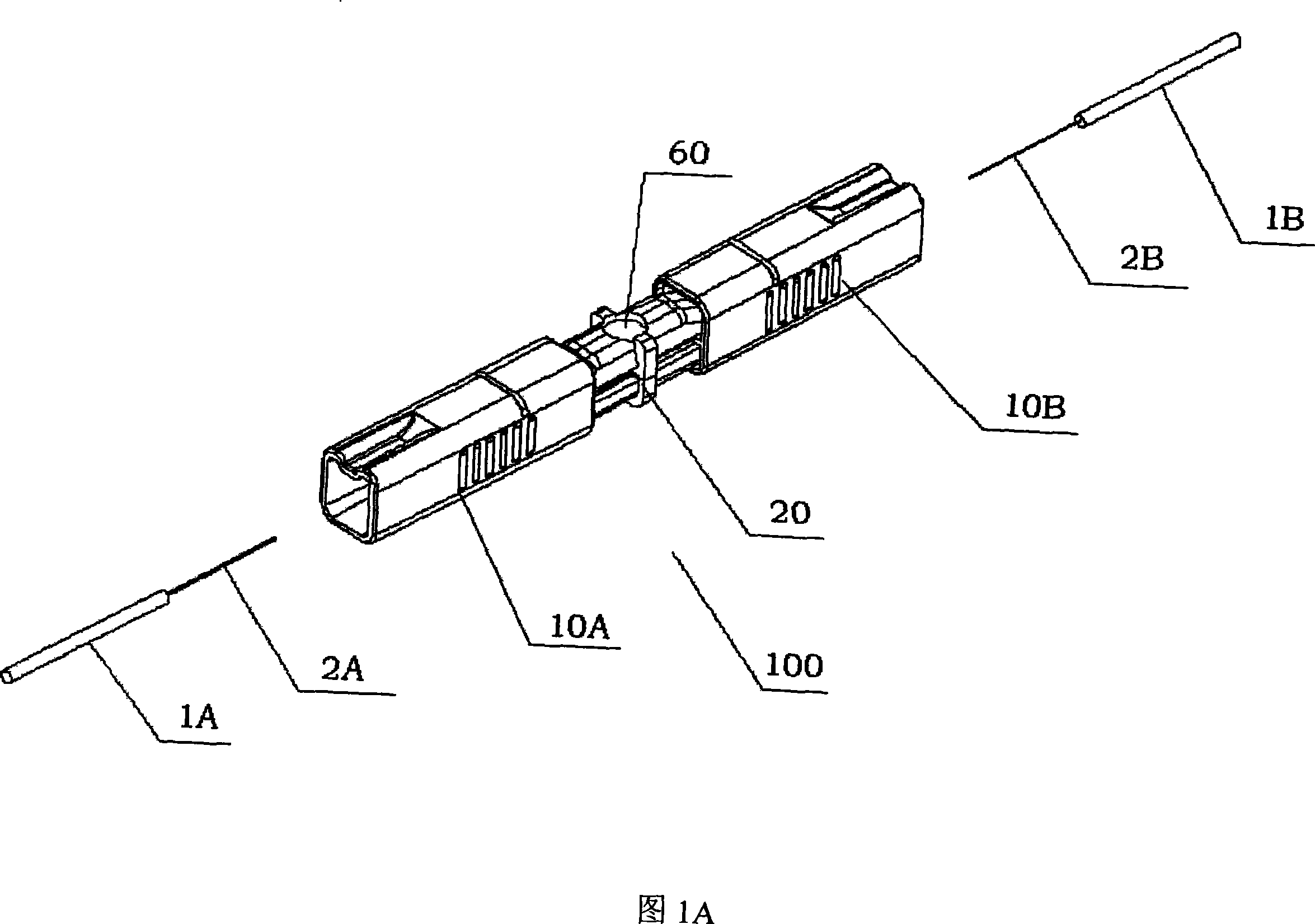

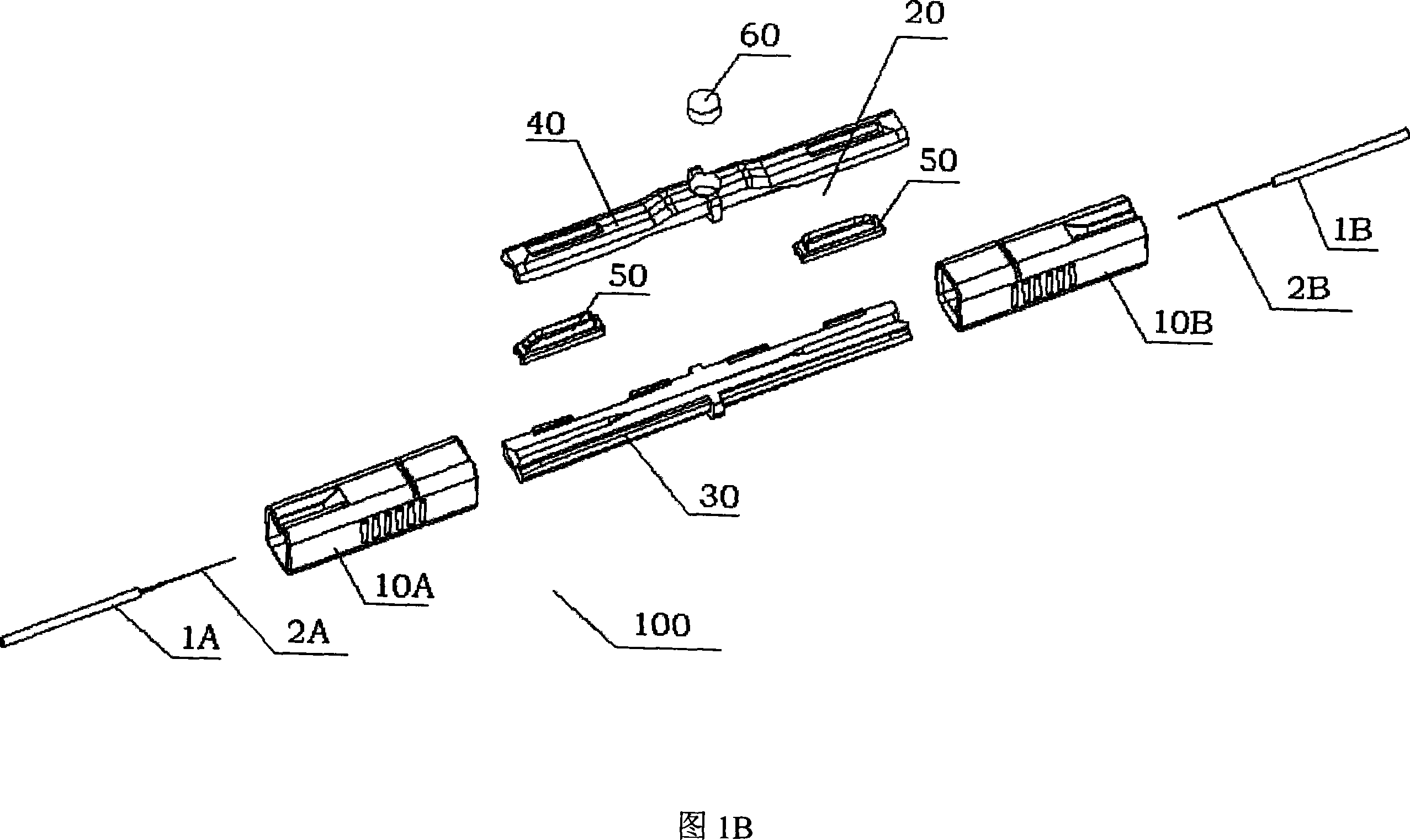

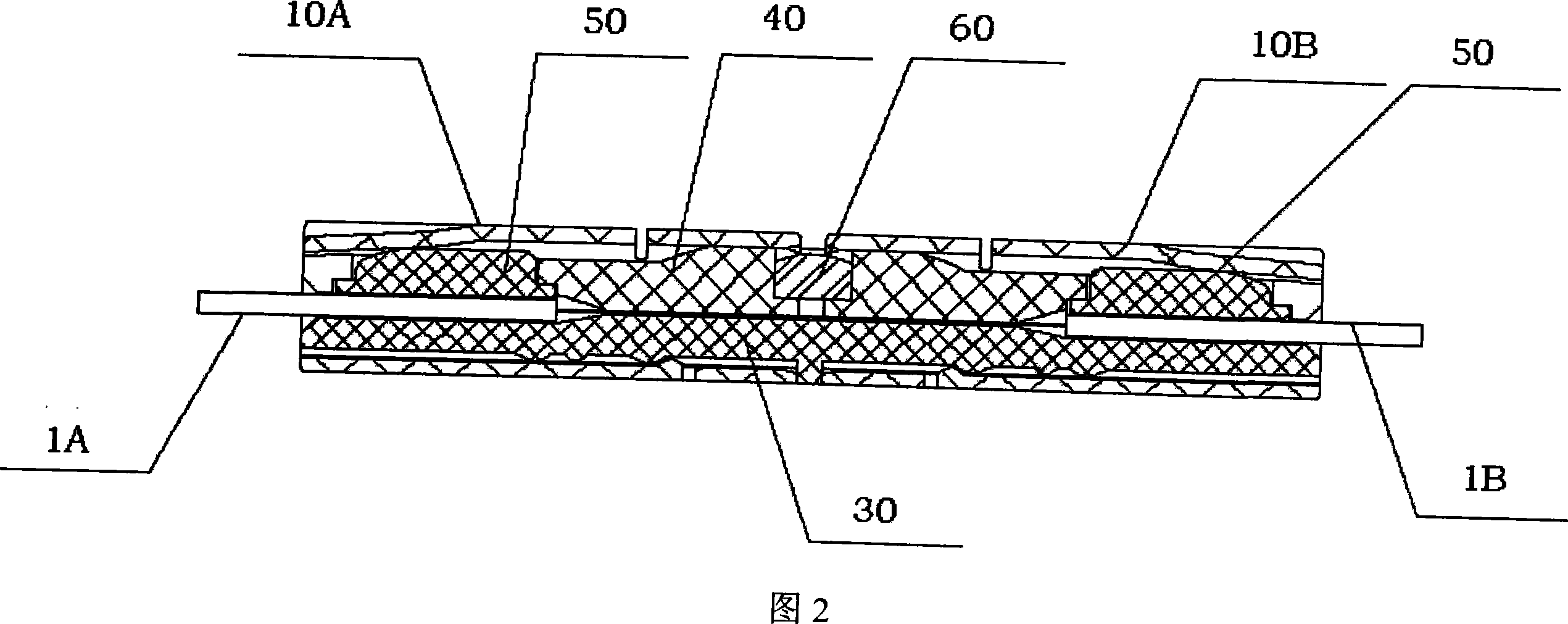

[0049] As shown in FIGS. 1A and 1B , the optical fiber connection device 100 is provided with a joint member 20 , a housing 10 , and a magnifying lens 60 . Optical fibers 1A and 1B are inserted from both ends of the connector as shown. Before the optical fiber 1 is inserted, a special tool should be used to remove the buffer coating of the optical fiber 1 for a specific length, so as to expose the bare optical fibers 1A and 1B, and then cut the bare optical fibers 1A and 1B to retain a certain length.

[0050] The joining member 20 is composed of a base part 30 , a pressure plate part 40 , and two cushion layer holding parts 50 . The buffer layer holding part 50 is embedded in the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com