Functianalised polyvinylaromatic nanoparticles

A vinyl aromatic, nano-particle technology, applied in the field of reinforcing fillers, can solve the problem of increasing the weight of the polymer matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

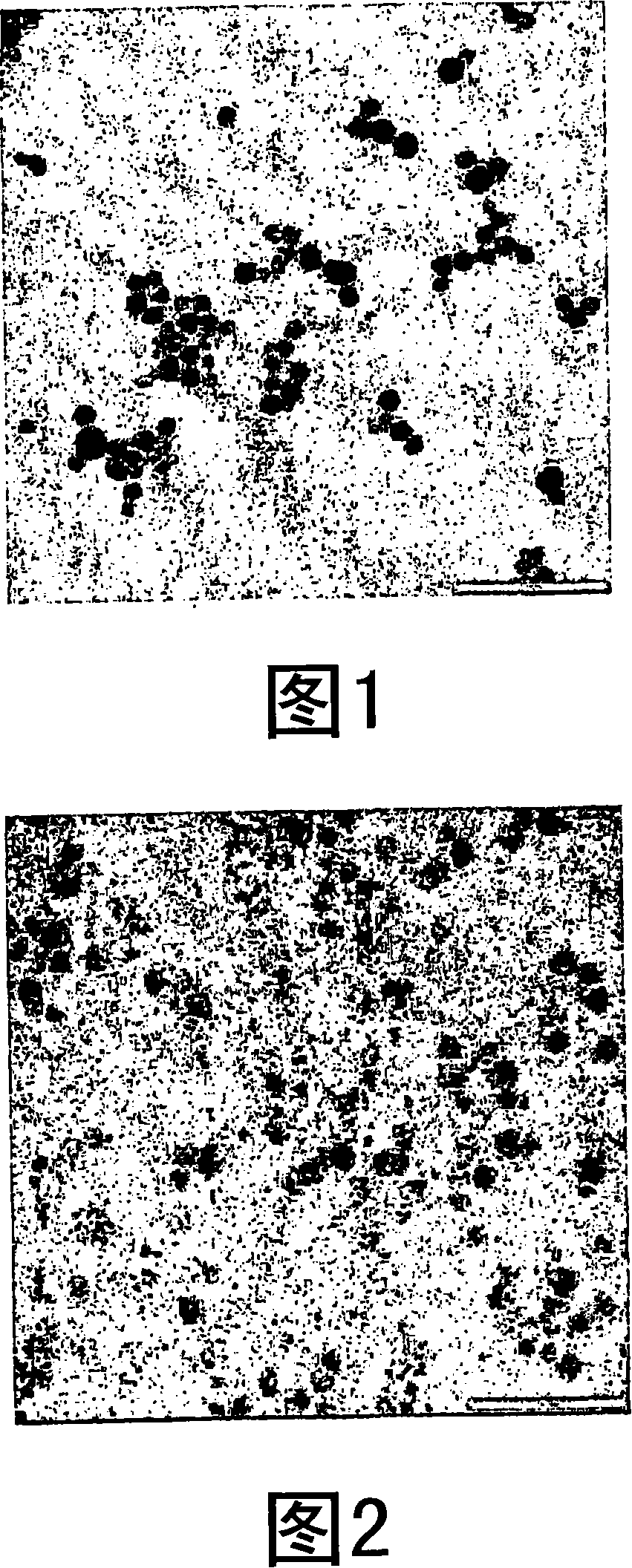

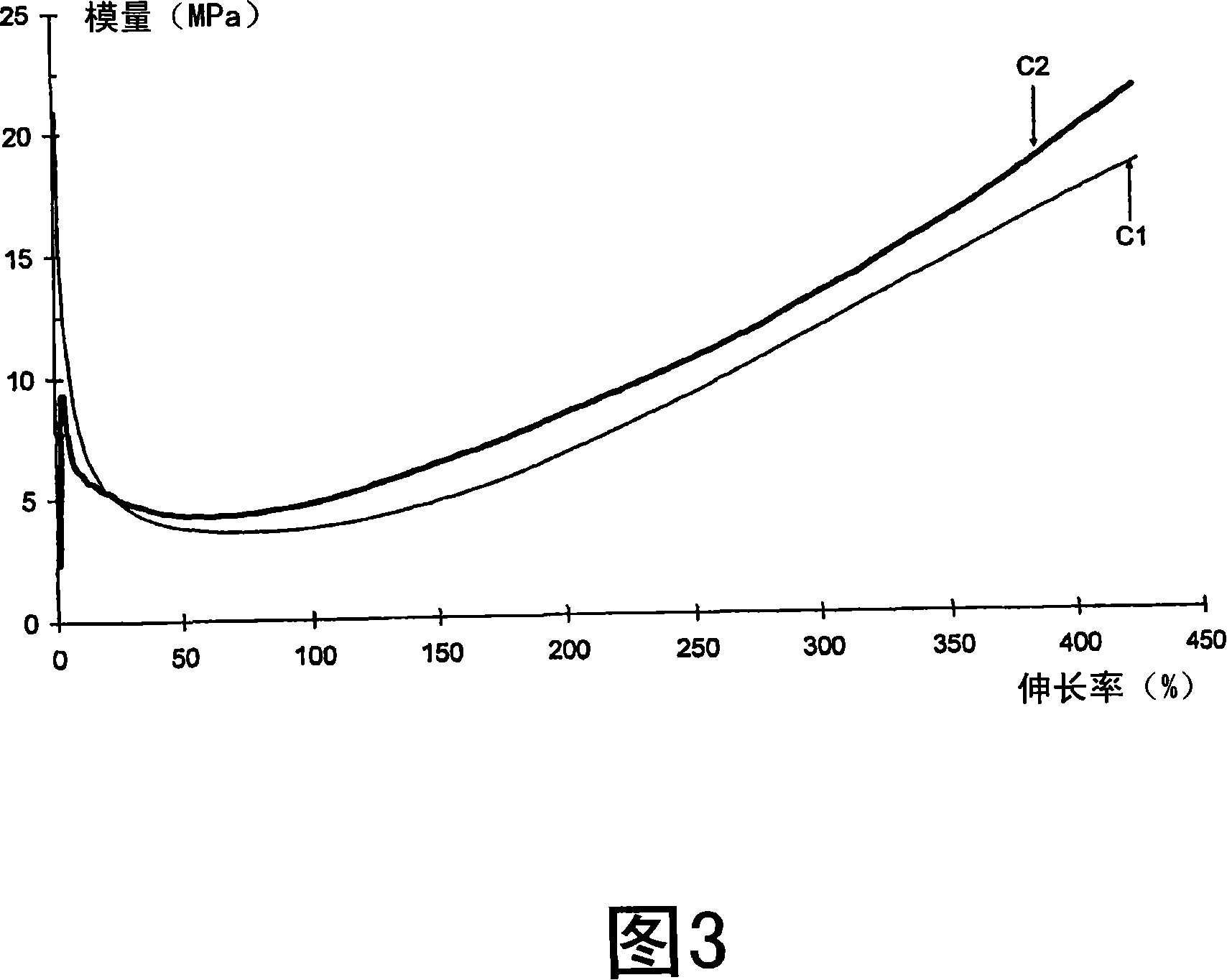

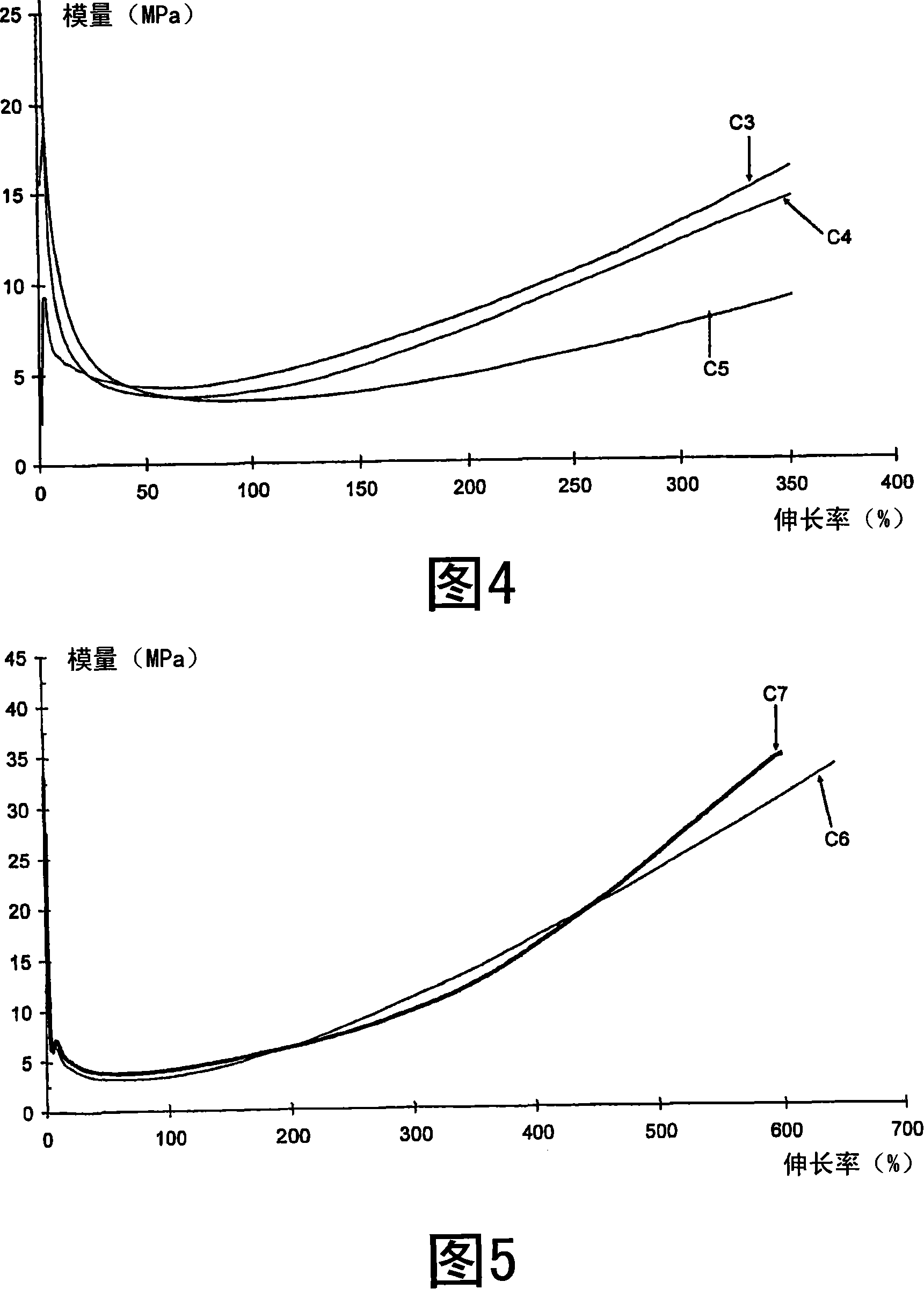

Image

Examples

Embodiment approach

[0053] According to a preferred embodiment of the present invention, Z satisfies one of the following formulas:

[0054]

[0055] in:

[0056] - Substituted or unsubstituted, same or different radicals R 1 selected from the following groups: C 1 -C 8 Alkyl, C 5 -C 8 Cycloalkyl and C 6 -C 12 aryl; and

[0057] - Substituted or unsubstituted, same or different radicals R 2 selected from the following group: hydroxyl, C 1 -C 8 Alkoxy and C 5 -C 8 Cycloalkoxy.

[0058] More preferably, in these formulae:

[0059] -base R 1 selected from the following groups: C 1 -C 4 Alkyl, cyclohexyl and phenyl, especially C 1 -C 4 Alkyl, more particularly methyl and ethyl; and

[0060] -base R 2 selected from the group consisting of: hydroxyl and C 1 -C 6 Alkoxy, especially hydroxyl and C 1 -C 4 Alkoxy is more particularly selected from hydroxy, methoxy and ethoxy.

[0061] Even more preferably, the group R 1 One is selected from methyl and ethyl, the base R 2 selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com