Wheat ridge-forming board and wheat ridge-forming seed-sowing machine

A seeder and forming board technology, which is applied in the field of agricultural machinery, can solve the problems of unfavorable use by ordinary farmers, troublesome maintenance or repair, and difficulty in popularization and use, and achieve the effects of improving light utilization rate, convenient operation, and facilitating promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

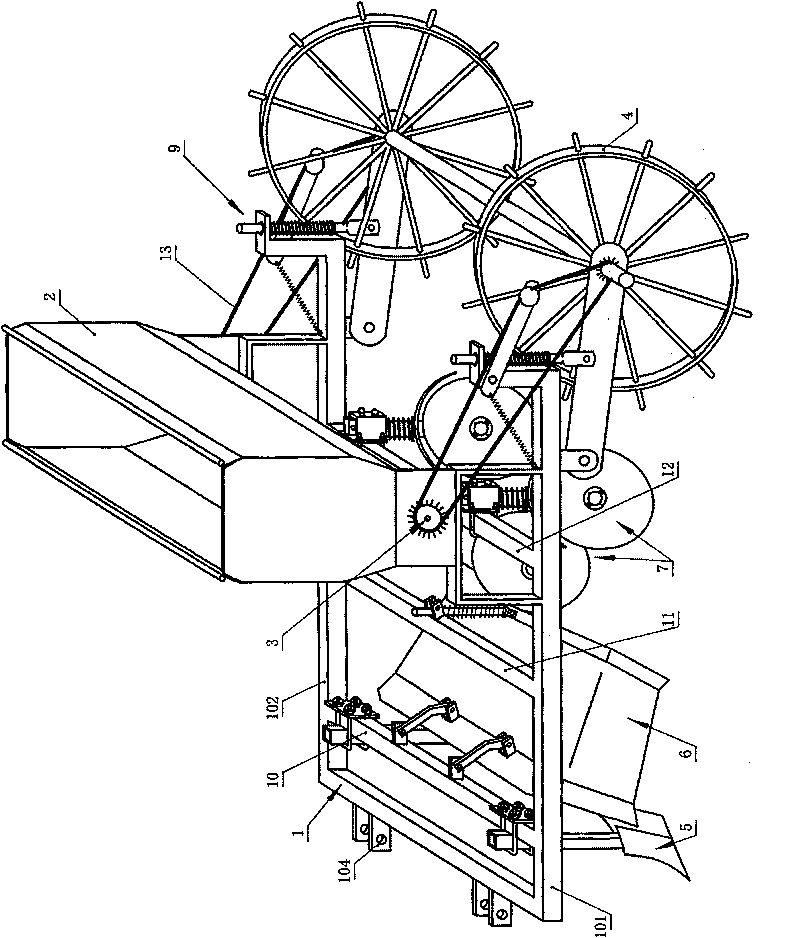

[0050] Embodiment one: see Figure 1-Figure 9-5 , Figure 14, a wheat ridge planter, comprising a frame 1, a soil lifter 5, a ground roller 4, a seed meter 3 and a sowing wheel 7, wherein two soil lifters 5 are fixedly installed on the front beam of the forming plate at the front end of the frame 1 10 On both sides of the symmetrical position, the soil lifting share 5 (5a is the left soil lifting share in the figure, and 5b is the right soil lifting share) includes an outer soil lifting share plate 502 and an inner soil lifting share plate 501, wherein the inner soil lifting share The area of the share plate 502 is greater than the area of the outside lifter plate 501 . A fixed connecting rod 503 is fixedly installed between the two soil lifting boards, and the fixed connecting rod 503 is fixed with the front beam 10 of the forming plate.

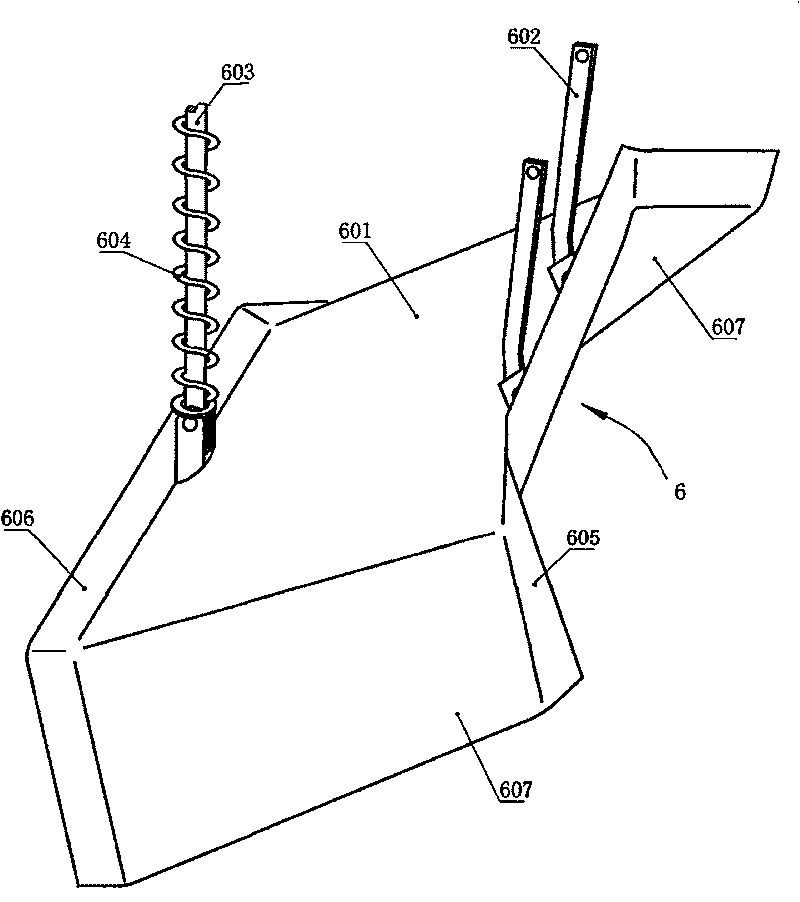

[0051] Behind the soil share 5, that is, between the soil share 5 and the sowing wheel 7, a forming plate 6 is installed. 601 and t...

Embodiment 2

[0058] Embodiment two: see Figure 10 , Figure 11 , numbering is identical with embodiment one, and meaning is identical, does not repeat, and difference is: six sowing wheels 7 are installed on the crossbeam 12 of the seed box 2 lower end of seed metering device 3 (no three groups, two in total group), on the front beam 10 of the forming plate, three soil lifters 5 are installed, and two parallel forming plates 6 are installed between the soil lifter 5 and the sowing wheel 7, each forming plate 6 corresponds to one group of sowing wheels 7, The area of the inboard soil share plate 501 of the soil lifter 5 on both sides is greater than the area of the outside lifter plate 502, and the both sides of the soil lifter in the middle position have the same area of the soil share plate. Or install two soil sharers 5 in the middle position, each group of lifter shares (one group by one side) the inner side lifter plate 501 area is greater than the outside lifter plate 502 area...

Embodiment 3

[0059] Embodiment three: see Figure 12 , Figure 13 , numbering is identical with embodiment one, and meaning is identical, does not repeat, and difference is: three sowing wheels 5 are installed on the crossbeam 12 of seed metering device 3 lower ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com