Multiple-effect wood fire retardant and method for preparing the same

A flame retardant, wood technology, applied in the direction of wood impregnation, wood impregnation, wood processing appliances, etc., can solve the problems of high processing cost, affecting the mechanical properties and gluing properties of wood, etc., and achieve the effect of reducing hygroscopicity and avoiding frost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

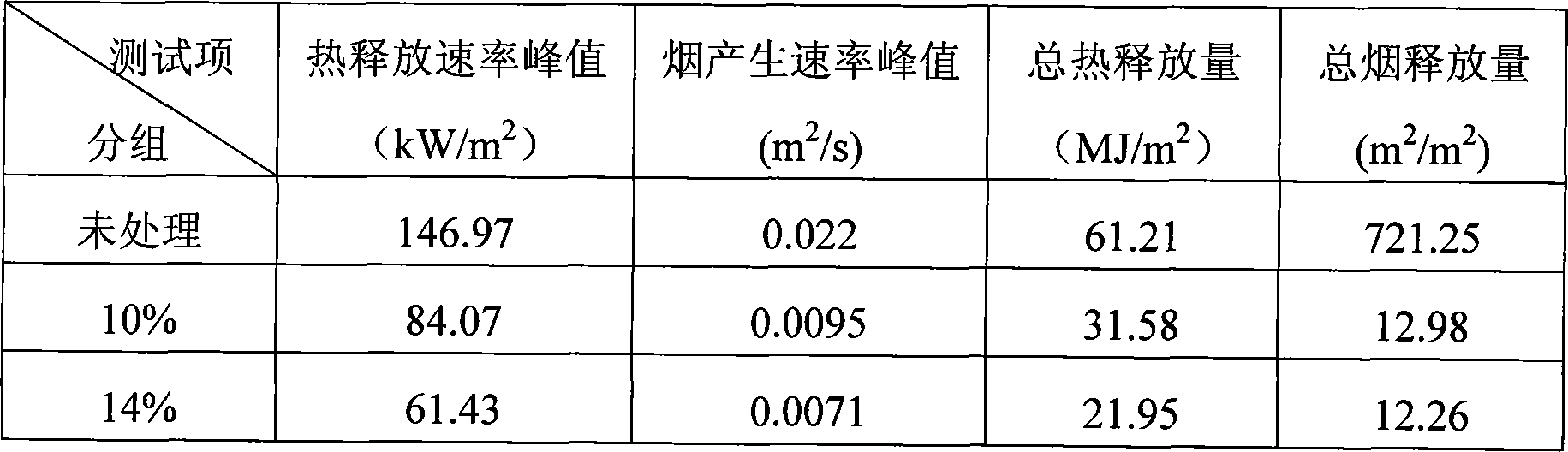

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The multi-effect wood flame retardant of this embodiment consists of 17 to 21 parts by weight of boric acid, 24 to 56 parts of guaninourea phosphate, 24 to 56 parts of ammonium dihydrogen phosphate, and 0.1 to 1.5 parts of hard water softener It is prepared by mixing and drying with 0.1 to 2 parts of antifungal agent.

specific Embodiment approach 2

[0011] Specific embodiment two: The multi-effect wood flame retardant of this embodiment consists of 18 to 20 parts of boric acid, 28 to 52 parts of guaninourea phosphate, 28 to 52 parts of ammonium dihydrogen phosphate, and 0.2 to 1.4 parts of hard water softener in parts by weight. It is prepared by mixing and drying with 0.2~1.8 parts of antifungal agent.

specific Embodiment approach 3

[0012] Specific embodiment three: The multi-effect wood flame retardant of this embodiment consists of 18.2-19.8 parts of boric acid, 32-48 parts of guaninourea phosphate, 32-48 parts of ammonium dihydrogen phosphate, and 0.4-1.2 parts of hard water softener in parts by weight. It is prepared by mixing and drying with 0.4~1.6 parts of antifungal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com