Rotary drum washing machine with transverse warm air fan and detachable filter

A pulsator washing machine and filter technology, applied in the field of washing machines, can solve the problems of inability to control the size, troublesome cleaning of the air inlet and filter of the washing machine, and reduced packing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

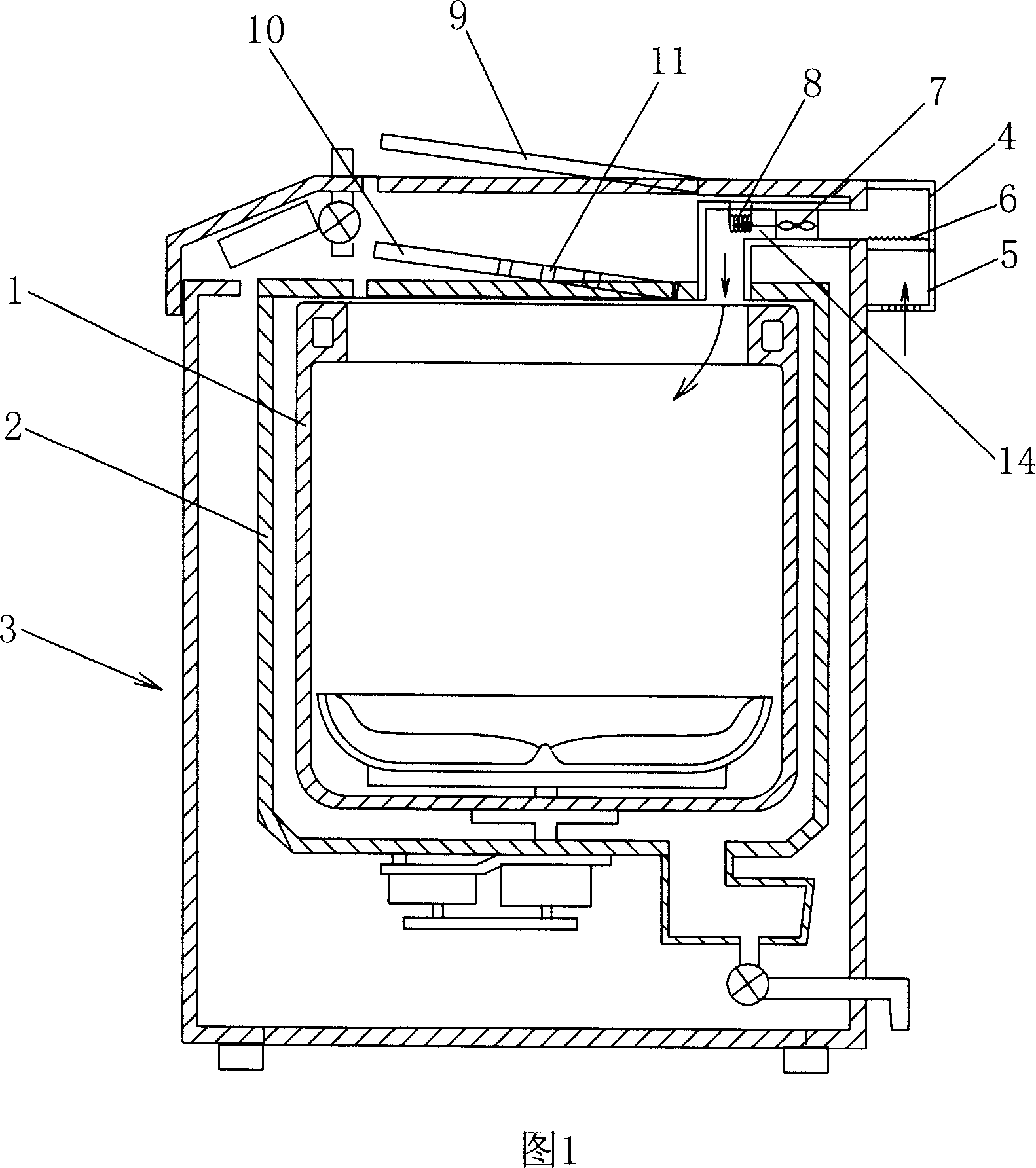

[0036] As shown in Fig. 1, the washing machine of the present invention comprises: a casing 3; a casing cover 9 arranged on the top of the casing 3; an outer tub 2 arranged in the casing, and an outer tub cover 10 is arranged on the opening side of the top of the outer tub 2 , the outer barrel cover 10 is provided with an air outlet hole 11; the inner barrel 1 which is rotated and arranged inside the outer barrel 2 has a large number of dehydration holes on its surrounding walls; the fan 7; the heater 8; the air duct 14; the air inlet 5; device 4.

[0037] In this embodiment, a kind of washing machine with air inlet and filter at the back is proposed. A detachable filter is arranged at the back of the washing machine. When in use, the air passes through the detachable filter at the back, is heated, and then enters the inner tub 1 through a pipe. An air outlet 11 is arranged on the outer bucket cover 10 of the outer tub, and the humid air after heat exchange with the clothes is...

Embodiment 2

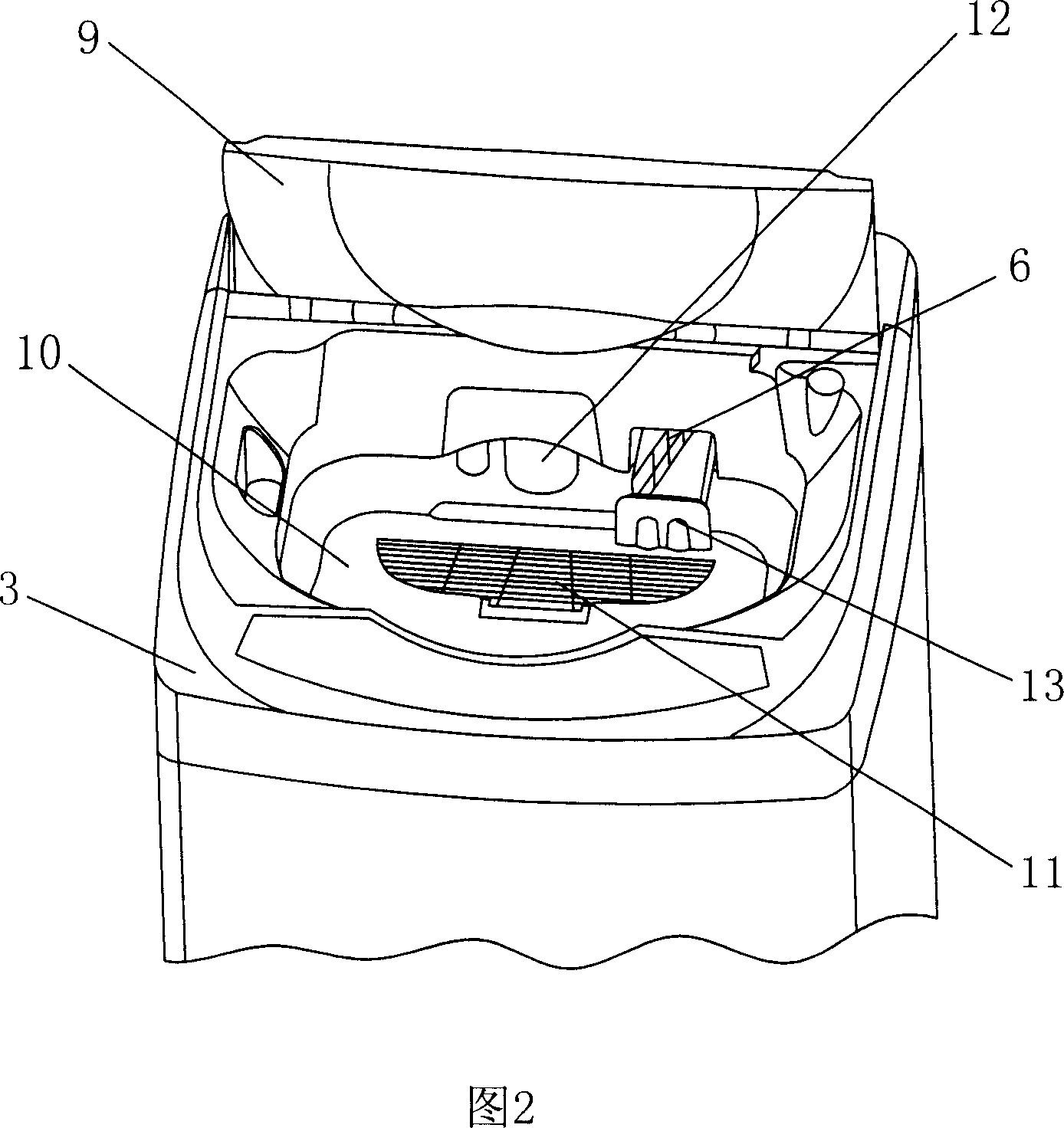

[0042] As a modification of Embodiment 1, the washing machine described in this embodiment is provided with an air inlet at the rear for air intake, but the filter is installed on the upper part of the outer tub of the washing machine in the form of a drawer.

[0043] As shown in Figure 2, the washing machine of the present invention comprises: a casing 3; an upper casing cover 9 arranged on the casing 3; an outer tub arranged in the casing, and an outer tub cover 10 is arranged on the opening side above the outer tub, The outer barrel cover 10 is provided with an air outlet hole 11; the inner barrel which is rotatably arranged inside the outer barrel 2 has a large number of dehydration holes on its surrounding walls; a fan; a heater; a warm air intake pipe 12; an air duct; an air inlet; a drawer Type filter 13, wherein, inner barrel, outer barrel, fan, heater, air channel and air inlet are not shown in the figure.

[0044] In this embodiment, a kind of washing machine with rear...

Embodiment 3

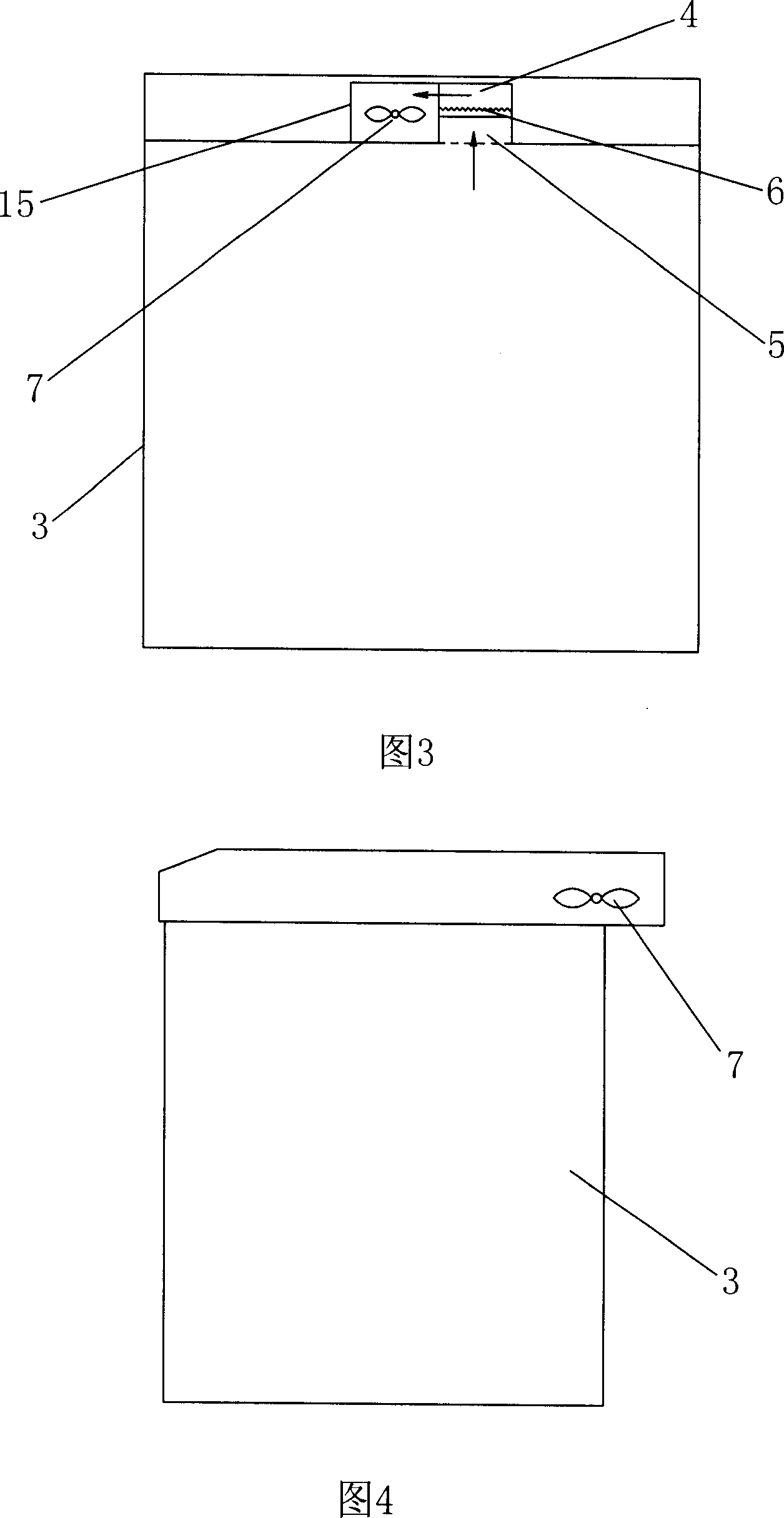

[0049] In Embodiment 1, a space box is arranged at the rear of the washing machine and the box-shaped air inlet side by side, so that the fan can partially rotate in the space box. As shown in Fig. 3 and Fig. 4, the component structure of the present invention is the same as that of Embodiment 1, and its difference is that a space box 15 is arranged at the side-by-side position of the air inlet 5 and the filter 4, and the fan 7 is installed near the casing 3. Position, the fan 7 has a part in the space box 15, the outside air enters the air inlet 5, is sucked into the space box 15 by the fan 7 after being filtered by the filter screen 6 in the filter 4, then enters the air duct and enters the inner barrel after being heated by a heater. The invention can save the inner space of the washing machine and increase the utilization rate of other equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com