Asphalt concrete elevated temperature property testing method

A technology of asphalt concrete and testing methods, applied in the direction of applying stable tension/pressure to test material strength, material inspection products, etc., can solve problems such as untenable analytical formulas, lack of confining pressure, incomplete compliance, etc., to overcome stress-strain distribution uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

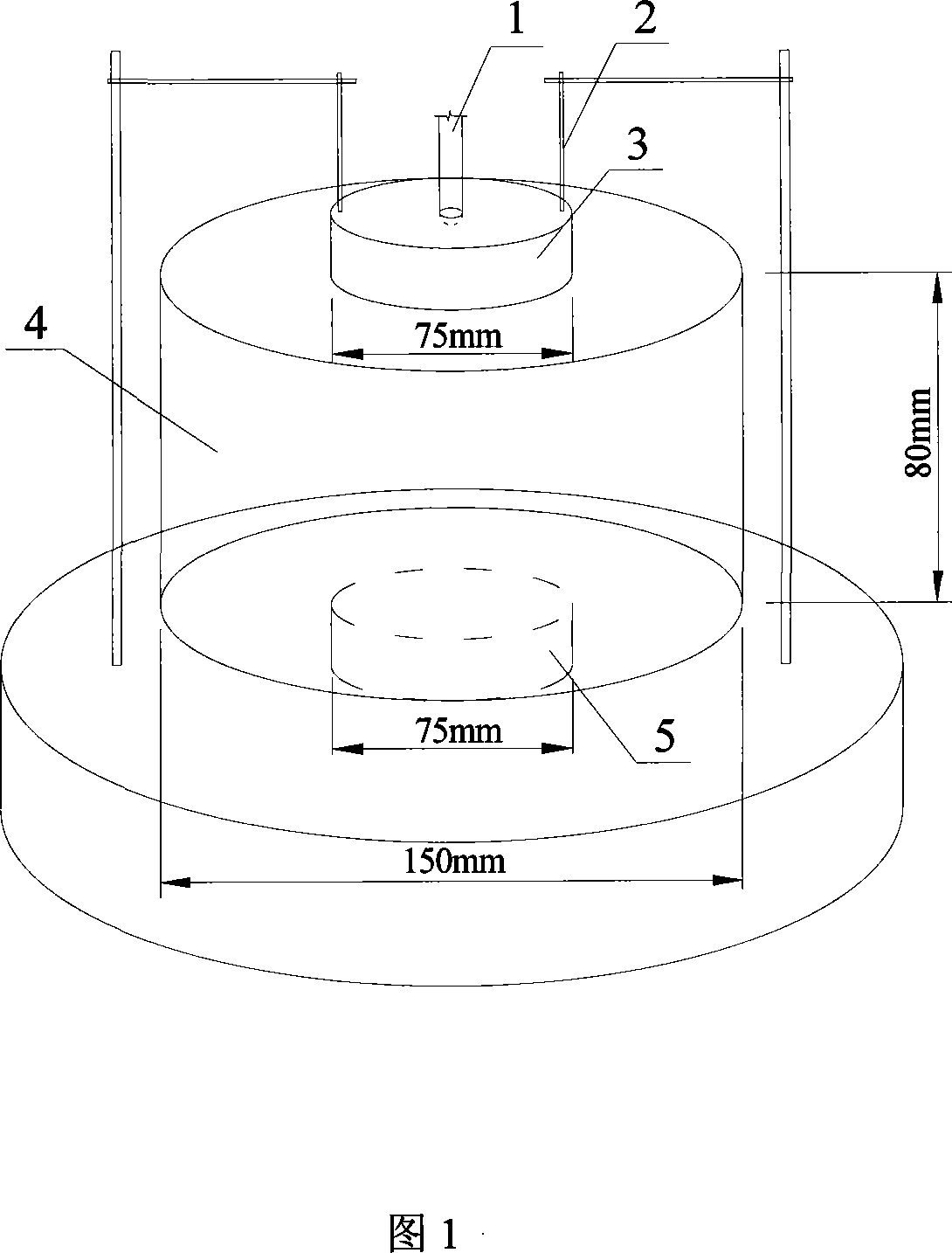

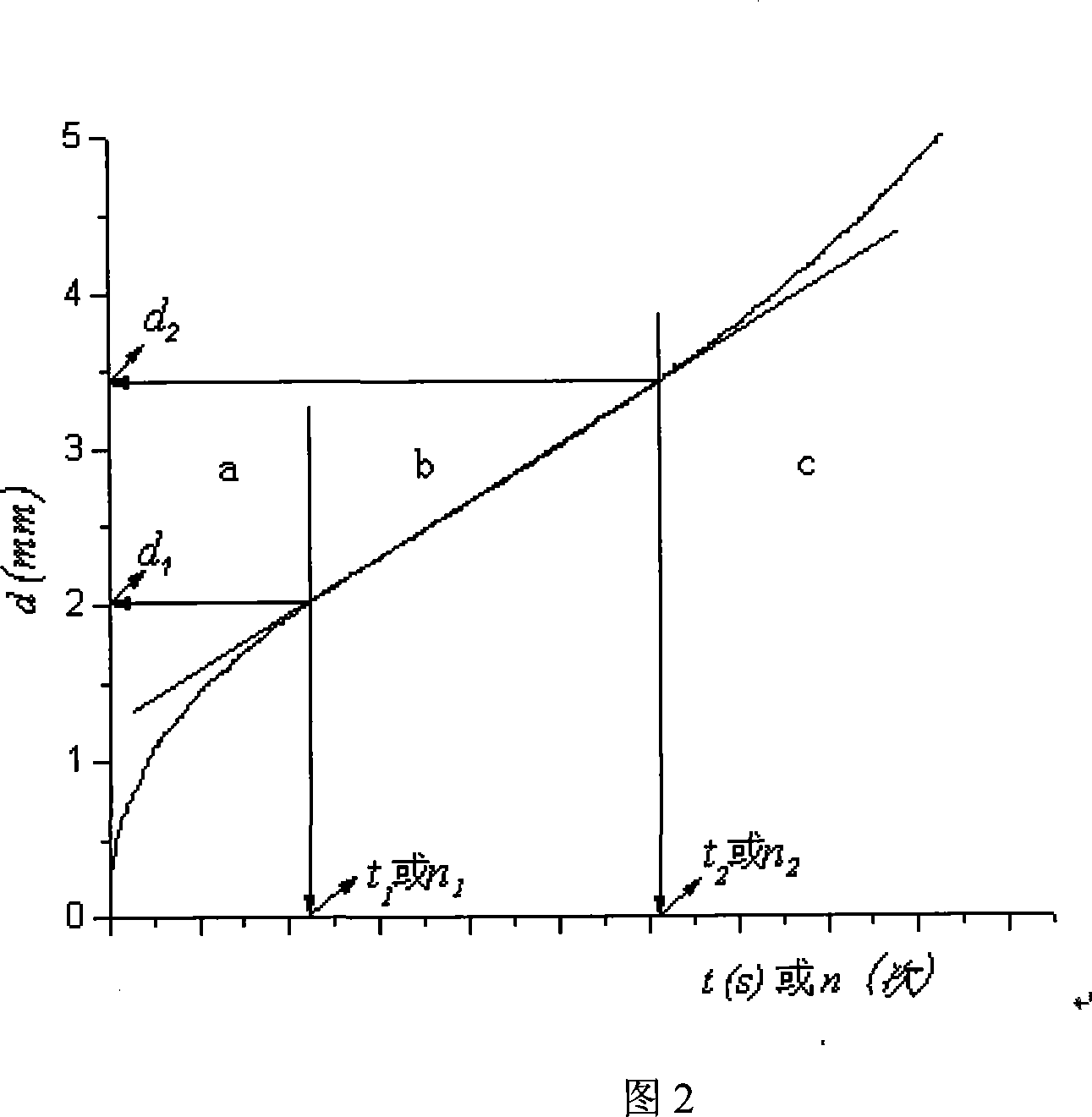

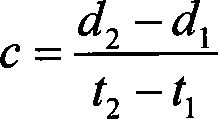

[0020] The design idea of the asphalt concrete high-temperature performance test method provided by the present invention is to retain the advantages of the penetration test and the rutting test on the one hand, that is, the mixture itself provides the confining pressure that changes with external factors to simulate the actual road surface mechanical state, and the other On the one hand, it draws on the advantage that the stress-strain state of the triaxial test is clear, and a little strain state can be obtained by measuring the deformation. The specific technical solution is to change the manually applied fixed confining pressure in the triaxial test to the variable confining pressure provided by the asphalt concrete itself in the penetration test. The loading test was carried out; in order to prevent the stress distribution and its inhomogeneity in the penetration test, a base smaller than the cross-sectional diameter of the cylindrical asphalt concrete specimen was used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com