Manufacture of lateral semiconductor devices

A lateral semiconductor, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex manufacturing and increasing the total on-resistance of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

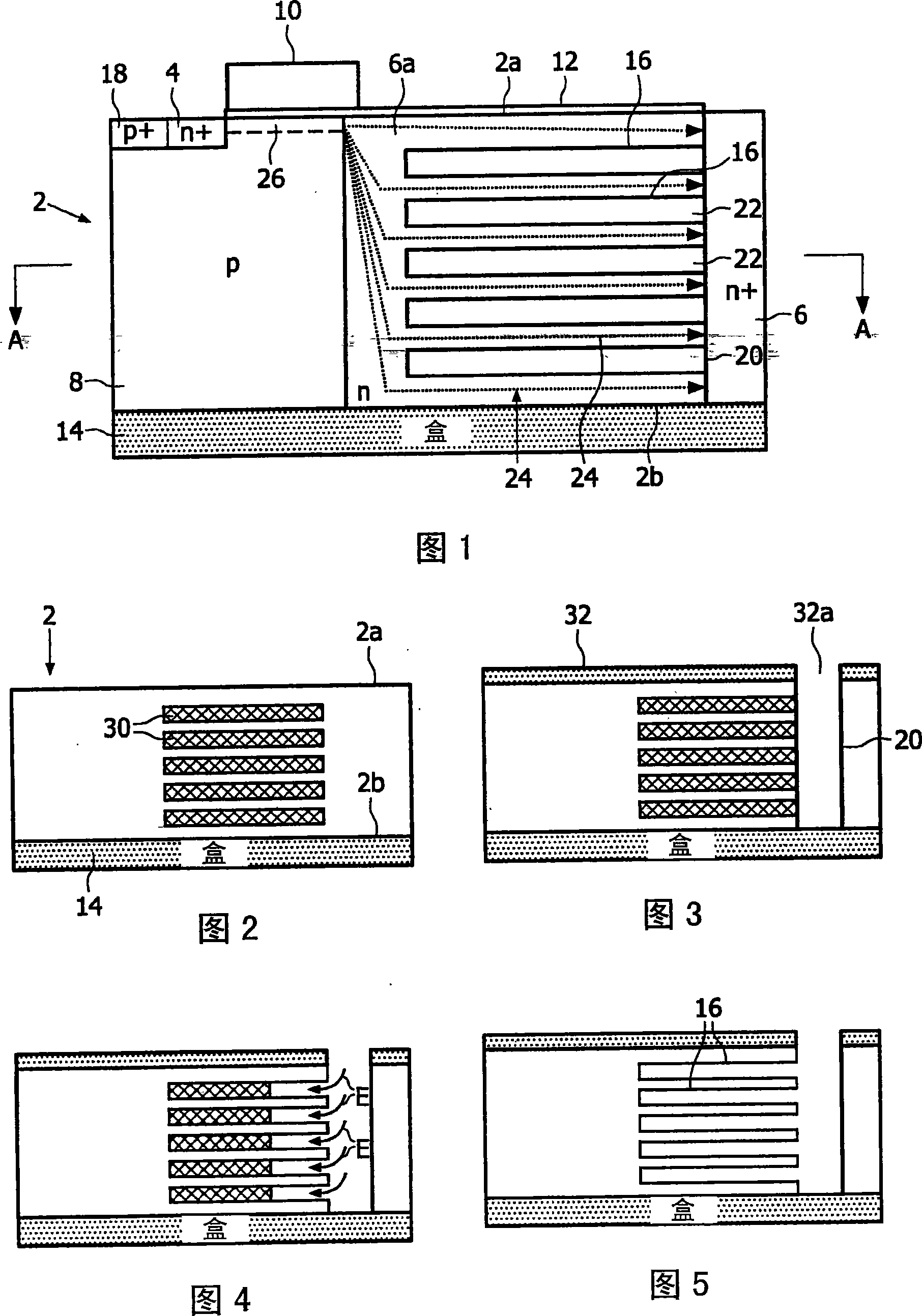

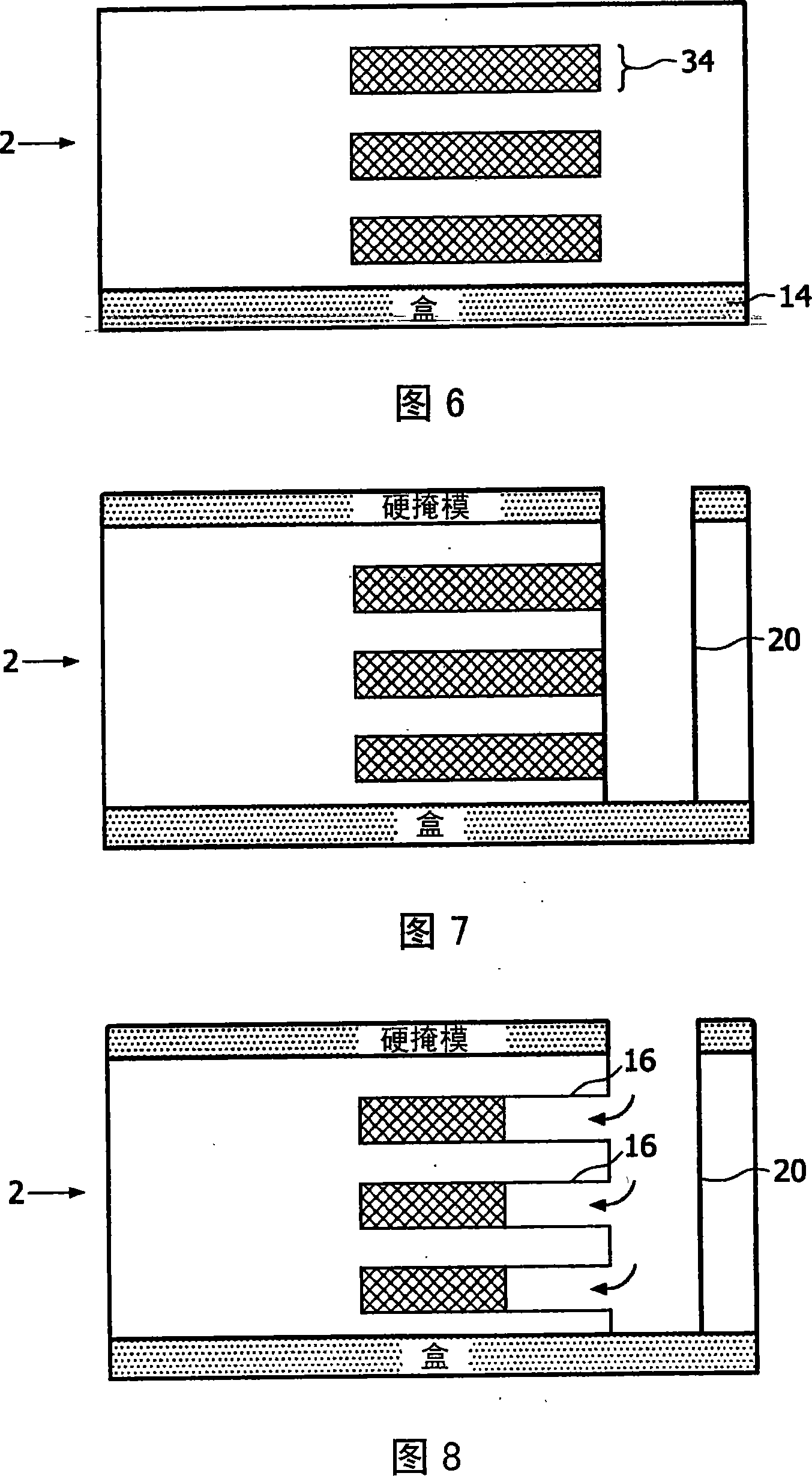

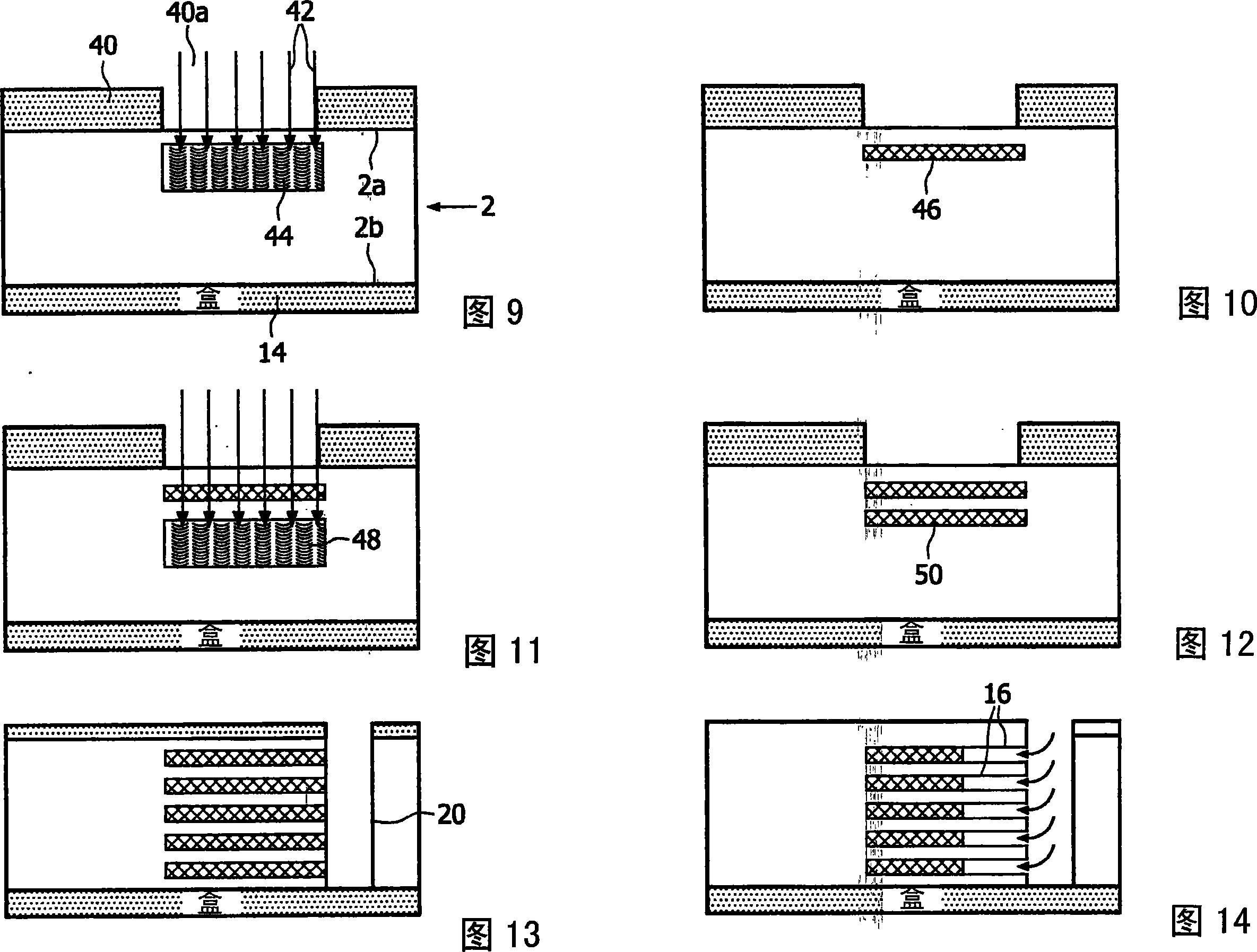

[0063] It should be noted that the diagrams are only diagrams and not drawn to scale. The relative sizes and proportions of the components of these figures have been enlarged and reduced in size, in order to express more clearly and conveniently in the figures. In modified or different embodiments, the same reference symbols are generally used to indicate corresponding or similar features.

[0064] Fig. 1 shows a cross-sectional side view of a device manufactured by a method according to an embodiment of the present invention. Specifically, the effective area of the device is displayed. The effective area can be bonded around its periphery by various well-known peripheral terminal configurations (not shown).

[0065] The device includes a source region 4 and a drain region laterally spaced apart therefrom. The drain region is composed of a drain drift region 6a that traverses the drain contact region 6 with a higher degree of doping. These regions form part of the semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com