Measurement mechanism of lens focal length, measurement method and thereof and optical quality evaluation method

A lens focal length and measuring device technology, which is applied in the direction of measuring devices, testing optical performance, optical instrument testing, etc., can solve the problems of many optical components, complex structure of adjustment mechanism, difficult installation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

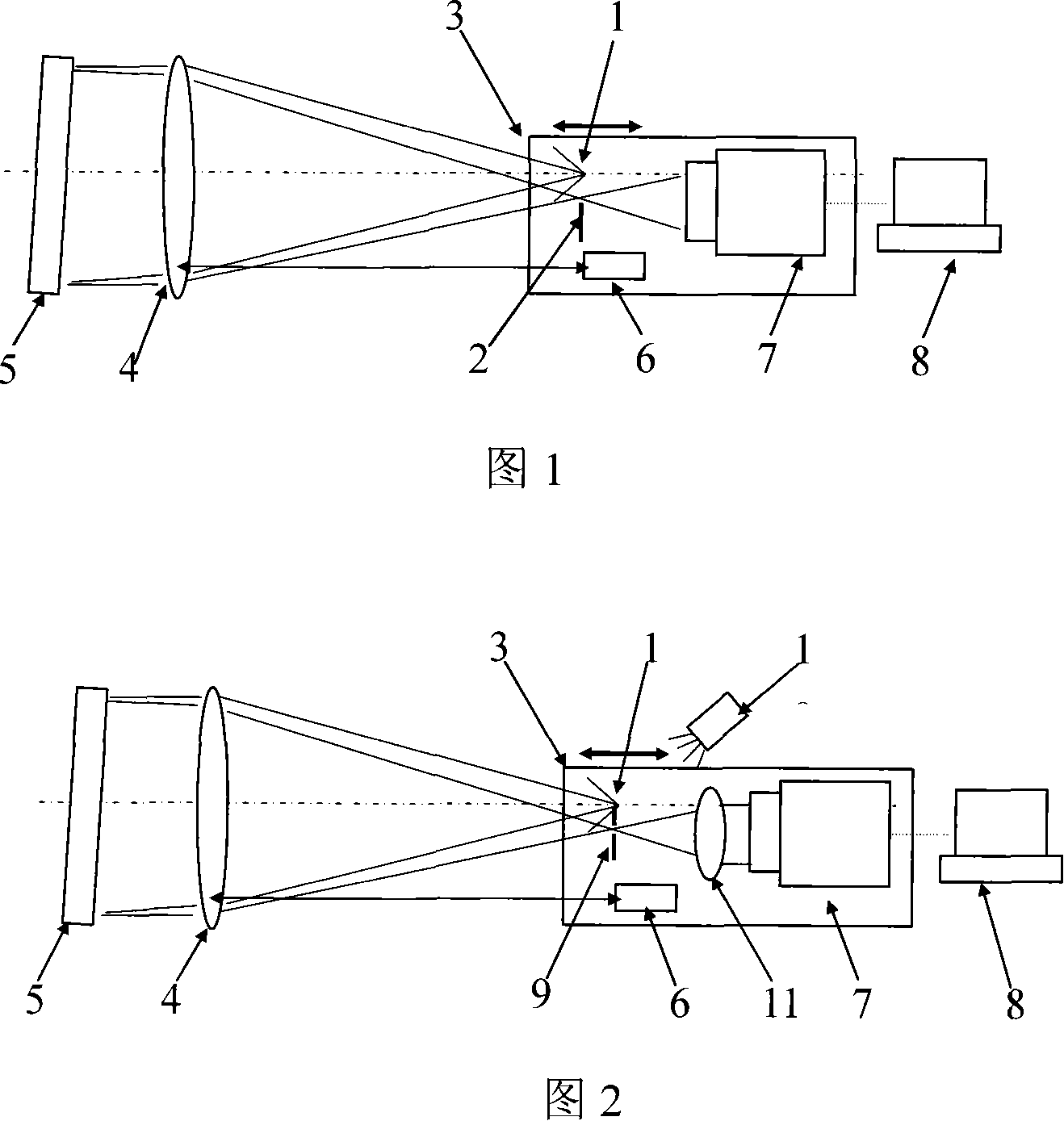

[0029] First please refer to Fig. 1, Fig. 1 is the structural representation of lens focal length measuring device of the present invention, as seen from the figure, the measuring device of lens focal length of the present invention is characterized in that its composition comprises: plane reflector 5, lens to be measured 4, point light source 1. Vertical knife edge 2, one-dimensional precision translation guide rail 3, laser range finder 6, CCD detector 7 and display 8, the positional relationship is as follows: plane reflector 5 and lens 4 to be measured are vertically installed on a platform , the point light source 1, the vertical knife edge 2, the laser range finder 6 and the CCD detector 7 are all fixed on the optical adjustment frame, and the optical adjustment frame is installed on the described one-dimensional precision translation guide rail 3, the one-dimensional precision The translation guide rail 3 is arranged along the main axis direction of the lens to be measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com