Liquid consuming battery with liquid regulating system

A fluid conditioning system, fluid consumption technology, used in battery packs and batteries, air-assisted and fuel cells and battery packs, which can solve the problems of occupying volume, increasing manufacturing cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

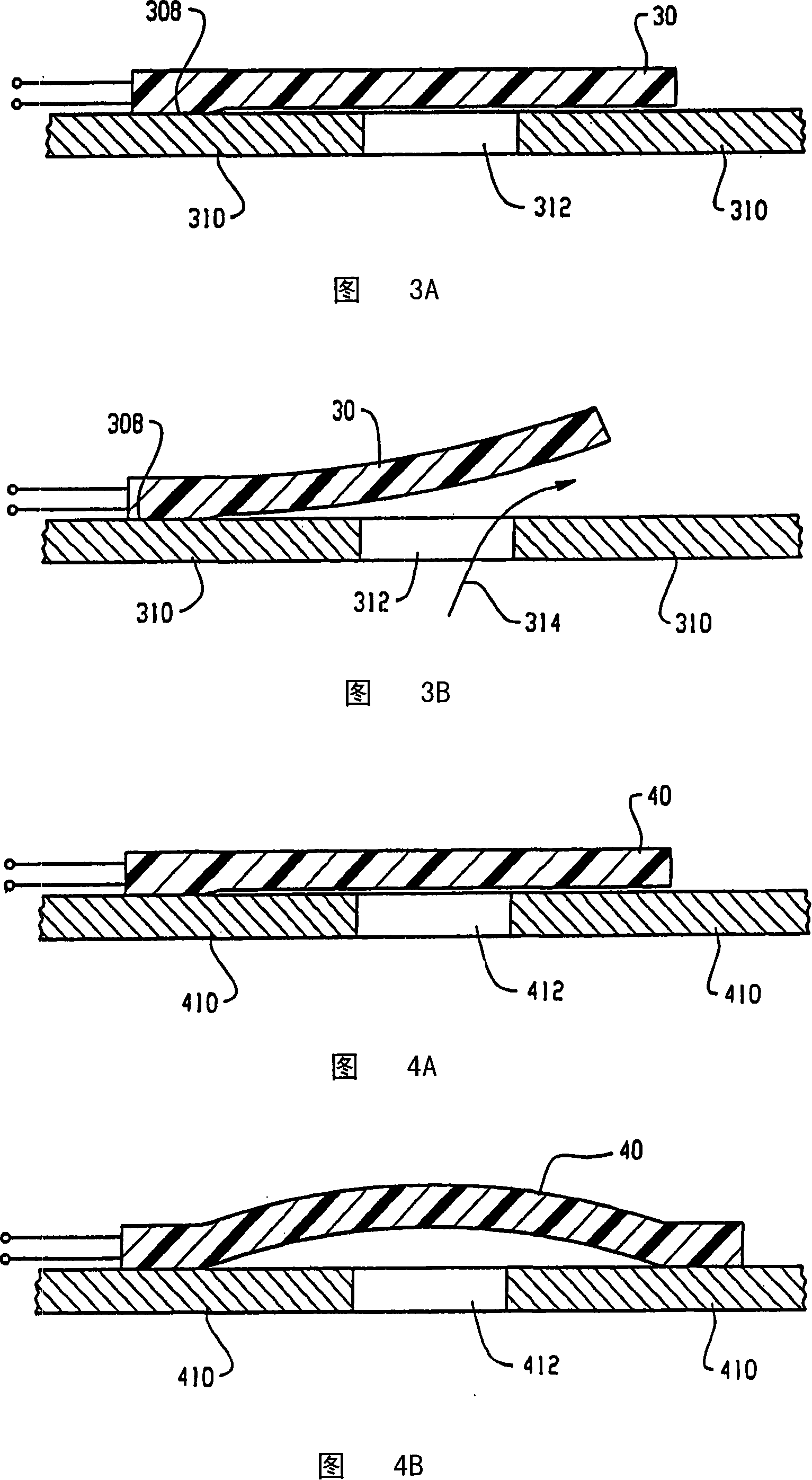

[0081] The actuator sheet can be prepared by any suitable method of preparation. A high speed printing process can be used to prepare the actuator film sheet. Slits may be made in the sheet to form flaps using a rotary die cutting process.

[0082]Another example of a suitable valve is a valve having two or more adjacent plates, each plate having one or more openings, which can be arranged at different angles to vary the size of the opening therethrough. The plates are usually relatively rigid to provide a proper seal in the closed position, movable relative to each other, for example by sliding one of the plates linearly across the other, by rotating one of the plates about an axis, or by sliding Multiple plates. In such an embodiment, the high permeability region of the valve may be part of one or more high permeability membranes adjacent to or secured to a surface of one of the sheets, or the high permeability region may be Only through the openings through adjacent shee...

Embodiment 1

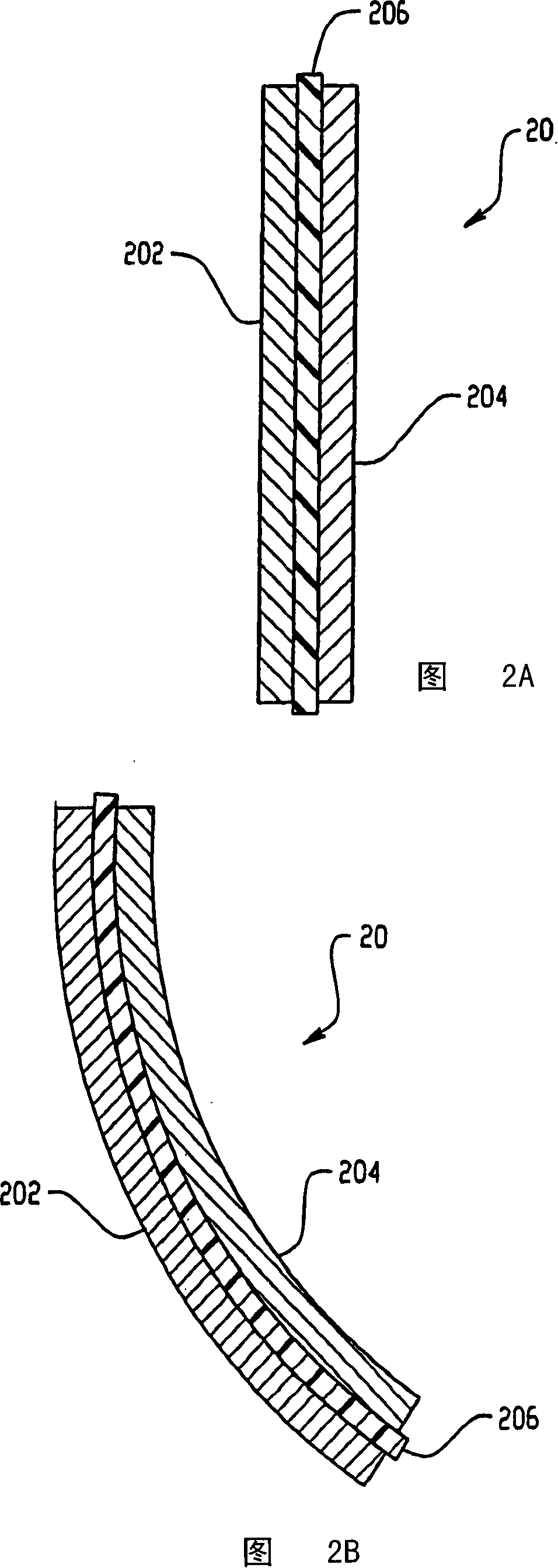

[0099] Prepare single electrode stimulator strips for testing.

[0100] By combining 75 wt% MnO 2 , 20% by weight of graphite and 5% by weight of polytetrafluoroethylene (PTFE) to prepare an electrode mixture. MnO 2 Electrolyte manganese dioxide (EMD), which is an alkaline battery grade, is available from Kerr-McGee Chemical Corp., Oklahoma City, OK, USA. Graphite was grade KS6 natural graphite powder available from Timcal America, Westlake, OH, USA. PTFE was TFE 6C grade TEFLON®, available from E.I. DuPont deNemours & Co., Chicago, IL, USA. Lightly mix the above ingredients using a mortar and pestle.

[0101] To each actuator, 5 g of this mixture was added with enough mineral spirits that the mixture could form a cohesive ball. The electrode mixture balls were rolled using a Swest mill to form electrode strips approximately 0.020 inches (0.508 mm) thick, 2 inches (5.08 cm) long, and 3 / 8 inch (0.953 cm) wide. The electrode strip was placed between two brass plates, press...

Embodiment 2

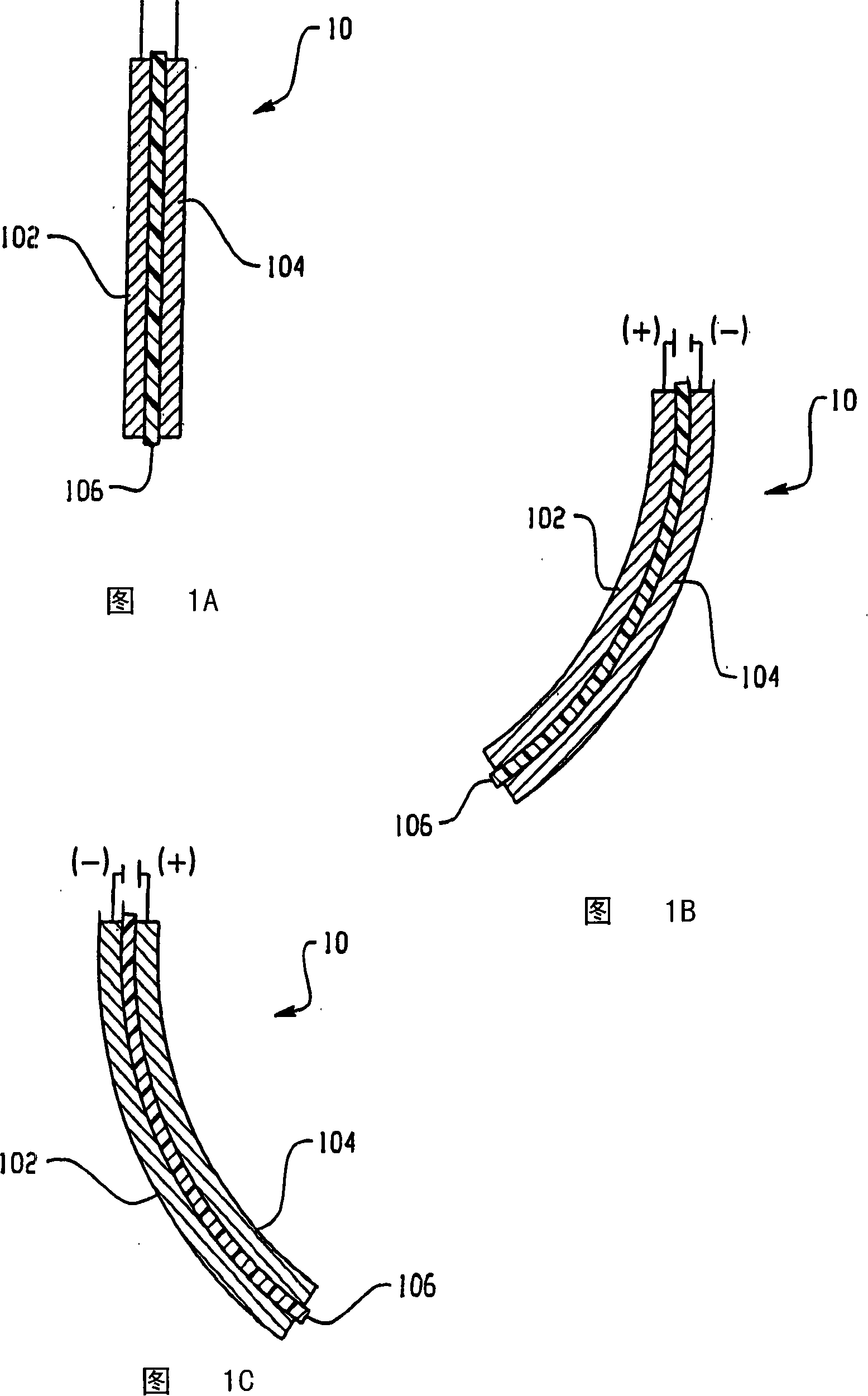

[0103] Two actuator bars prepared as described in Example 1 were tested to determine their ability to repeatedly bend and straighten when an electric potential was applied.

[0104] Prepare stimulator strips for testing. Lay the exciter strips side by side, keeping the nickel mesh sides away from each other. Fix the extended nickel mesh together so that the two stimulator strips serve as a single working electrode in the test. The stimulator strip was immersed in a beaker containing an aqueous KOH electrolyte along with a zinc reference electrode and a Pt counter electrode.

[0105] The exciter was alternately discharged and then charged with a constant current of about 0.01278 amp for a total of 4 discharge / charge cycles. The first discharge lasted about 70 minutes, and subsequent discharges and all charges were about 80 minutes each. Observe the exciter bar. Both strips bend during discharge, moving the free ends away from each other, and then straighten during charging,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com