Shuttle box driving device for computer flat machine

A driving device and technology of computerized flat knitting machine, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems affecting the types of knitting machine patterns, the large space occupied by the transmission mechanism, and the complexity of the shuttle box transmission mechanism, etc., to achieve the goal of knitting Superior performance, improved cost performance, accurate and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

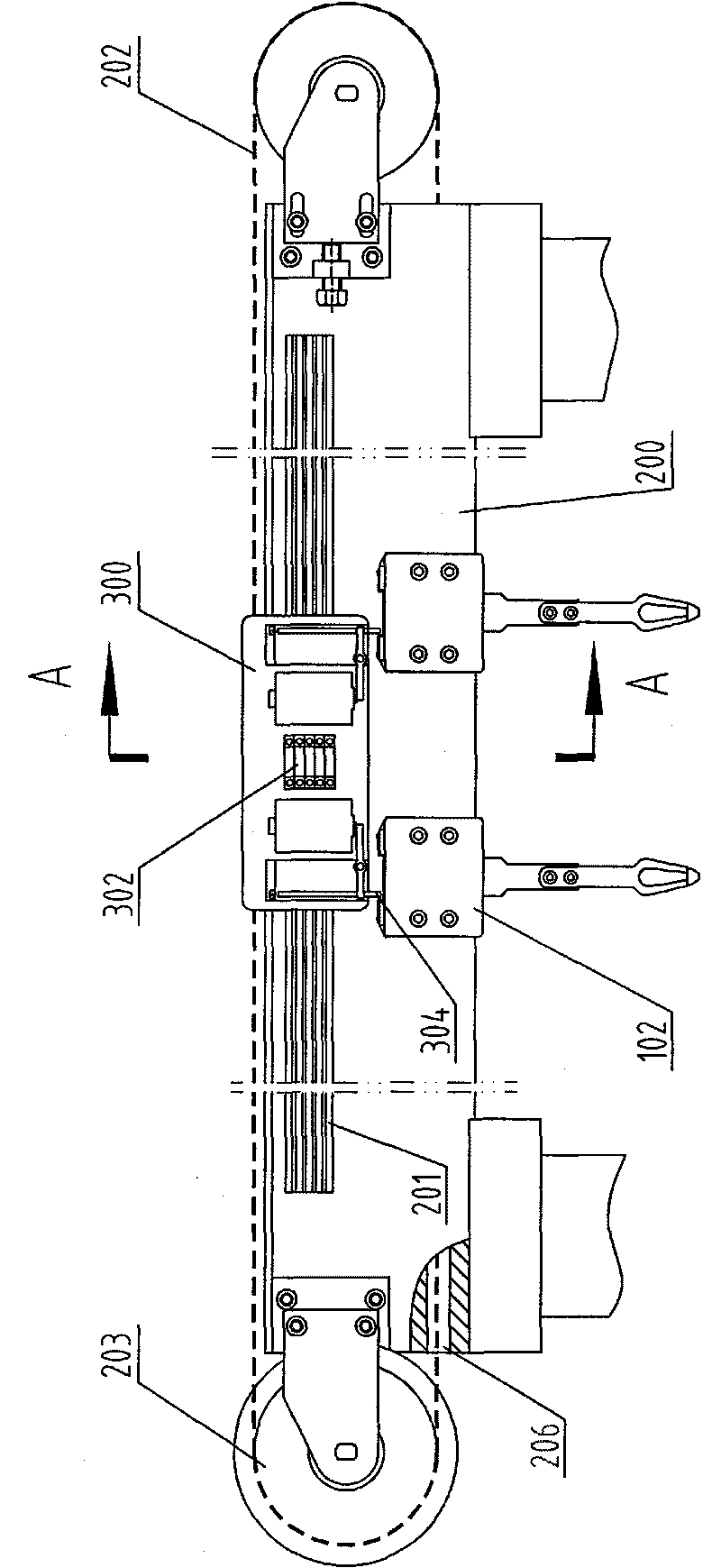

[0023] control figure 1 , the synchronous wheel 203 is fixed on the two ends of the shuttle bar 200, and the synchronous belt 202 wraps the two synchronous wheels 203, and the shuttle box control mechanism connection 300 placed on both sides of the shuttle bar 200 is connected with the synchronous belt 202, and the synchronous wheel 203 meshes and drives synchronously. The belt 202 drives the shuttle box control mechanism 300 to move along the shuttle bar 200 .

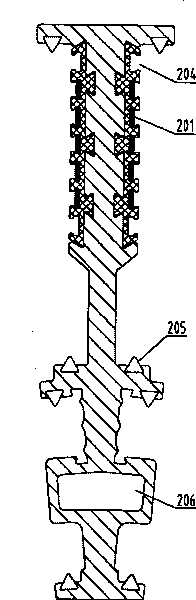

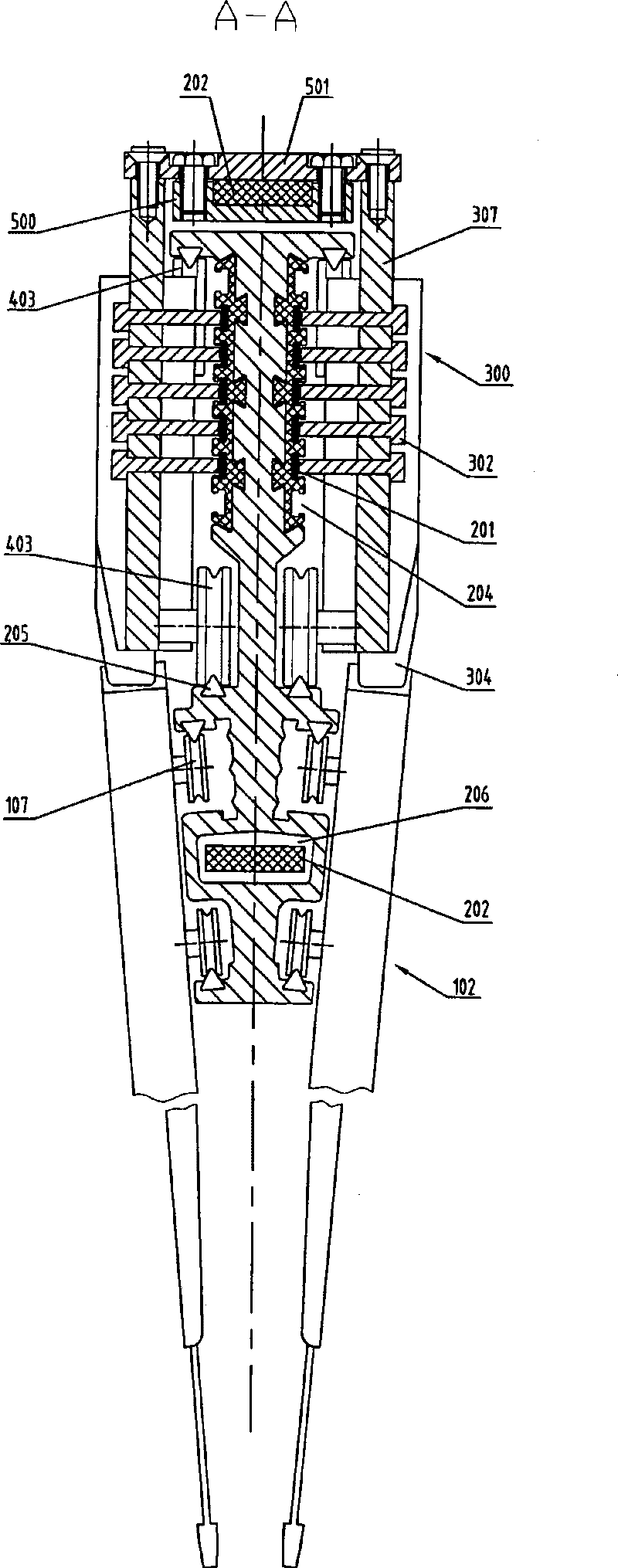

[0024] control figure 2 , image 3 , The lower part of the shuttle bar 200 is provided with a surrounding hole 206 along its length, the timing belt 202 passes through the hole and meshes with the synchronous wheel 203 and moves around the shuttle bar 200 . On both sides of the upper part of the shuttle bar 200, three brush slots 204 are arranged along the length direction of the shuttle bar, and a conductive sheet 201 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com