Ceramic lamp and making method thereof

A technology of ceramic metal halide lamps and ceramics, which is applied to clay products, household utensils, and other household utensils. It can solve the problems of consuming large metal mineral resources, high pollution, and low safety, and achieve long-lasting color without deterioration and safety. High coefficient, the effect of saving metal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ceramic metal halide lamp

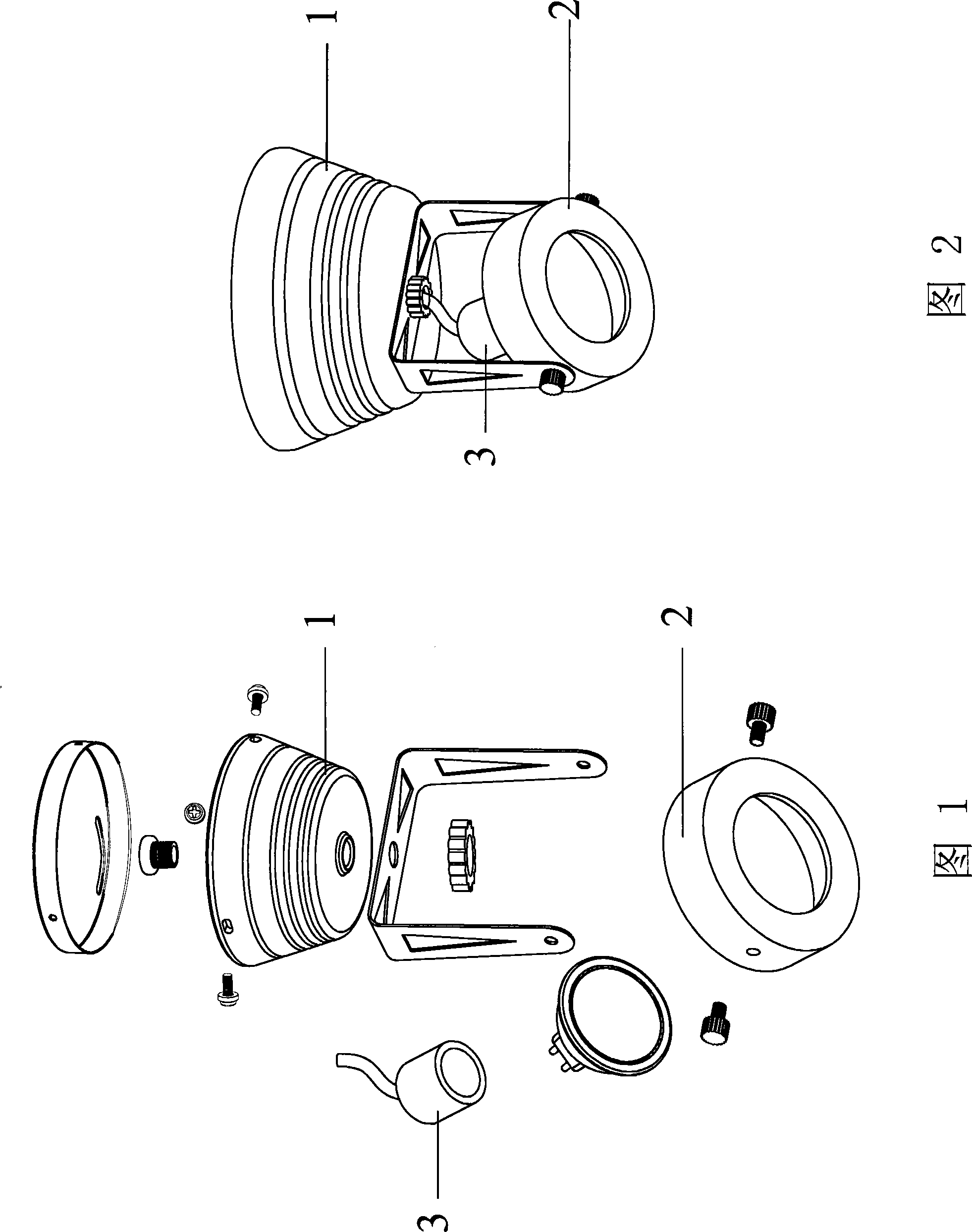

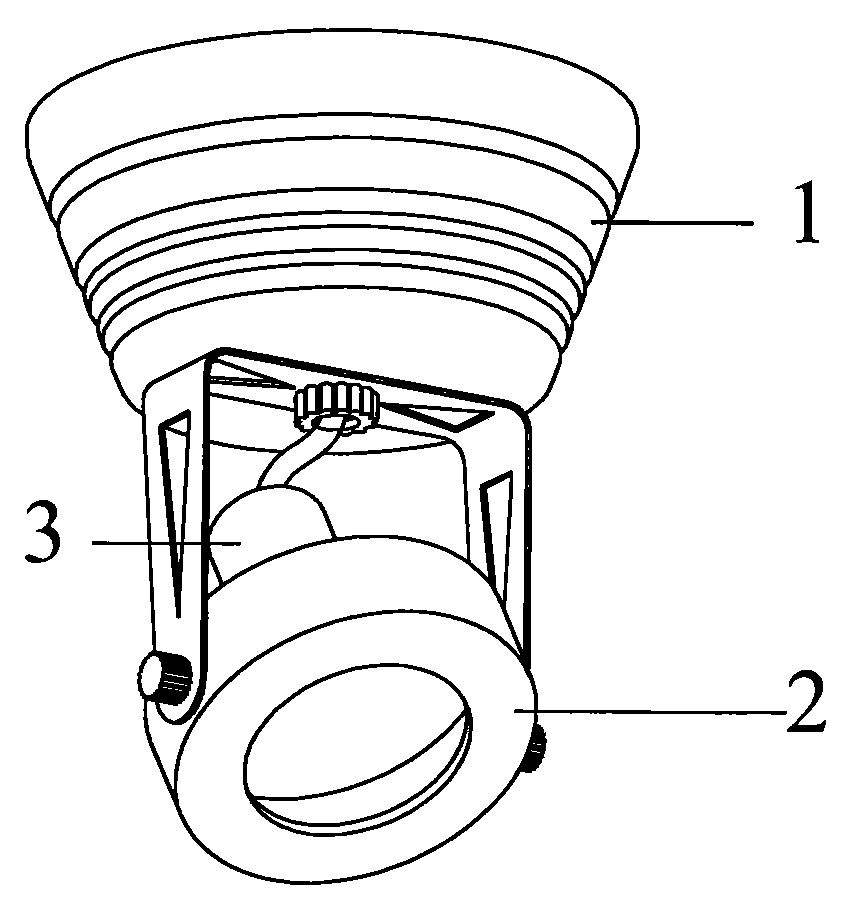

[0034] as attached figure 1 As shown, the lamp body 1 , the dough ring 2 and the lamp cap 3 in the ceramic metal halide lamp of this embodiment are parts made of ceramic materials.

[0035] The specific preparation method is as follows:

[0036] 1) Make a lamp body 1, a dough ring 2 and a lamp holder 3 by using a molding pot with pottery clay;

[0037] 2) Color glaze is applied on the surface of the lamp body 1, dough ring 2 and lamp base 3 pottery blank prepared in step 1);

[0038] 3) Sintering the part ceramic blank prepared in step 2) at a high temperature according to a conventional method to make a ceramic lamp body 1, a dough ring 2 and a lamp holder 3;

[0039] 4) Install the ceramic lamp body 1, dough ring 2 and lamp cap 3 prepared in step 3) together with conventional light-emitting parts, conductive parts, screws, brackets, nuts and bottom cover according to the conventional method into the ceramic metal halide lamp of the prese...

Embodiment 2

[0041] ceramic decorative lamp

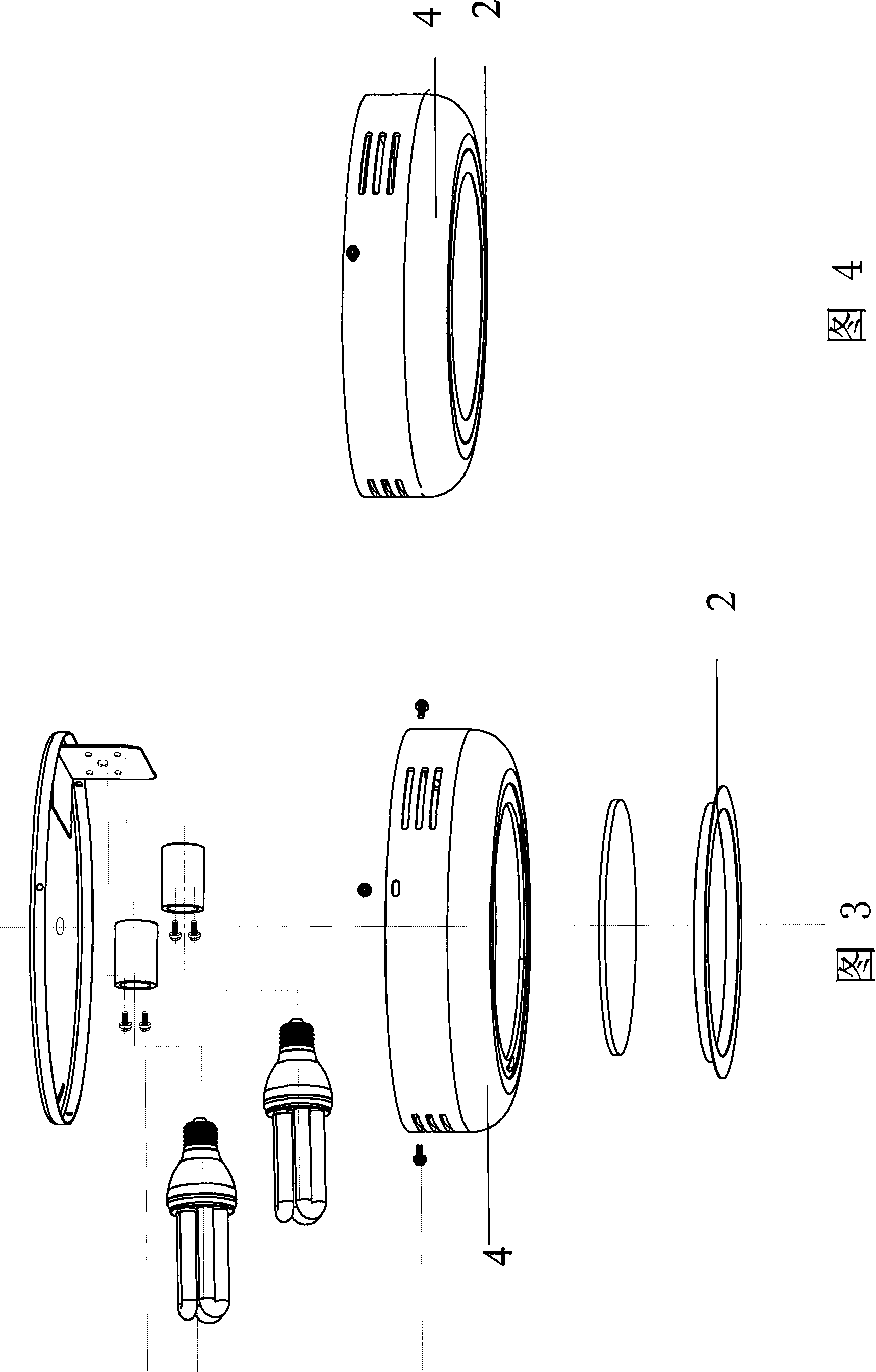

[0042] as attached image 3 As shown, the lamp tube 4 and the dough ring 2 in the ceramic decorative lamp of this embodiment are parts made of ceramic materials.

[0043] The specific preparation method of the ceramic parts is the same as in Example 1, and then the prepared ceramic lamp tube 4 and the face ring 2 are installed together with the conventional light-emitting parts, conductive parts, screws, brackets, nuts and bottom cover according to the conventional method to the ceramic decoration of the present invention. lights (see attached Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com